MAC- 440 Centre de fabrication profilés aluminium

MAC- 440

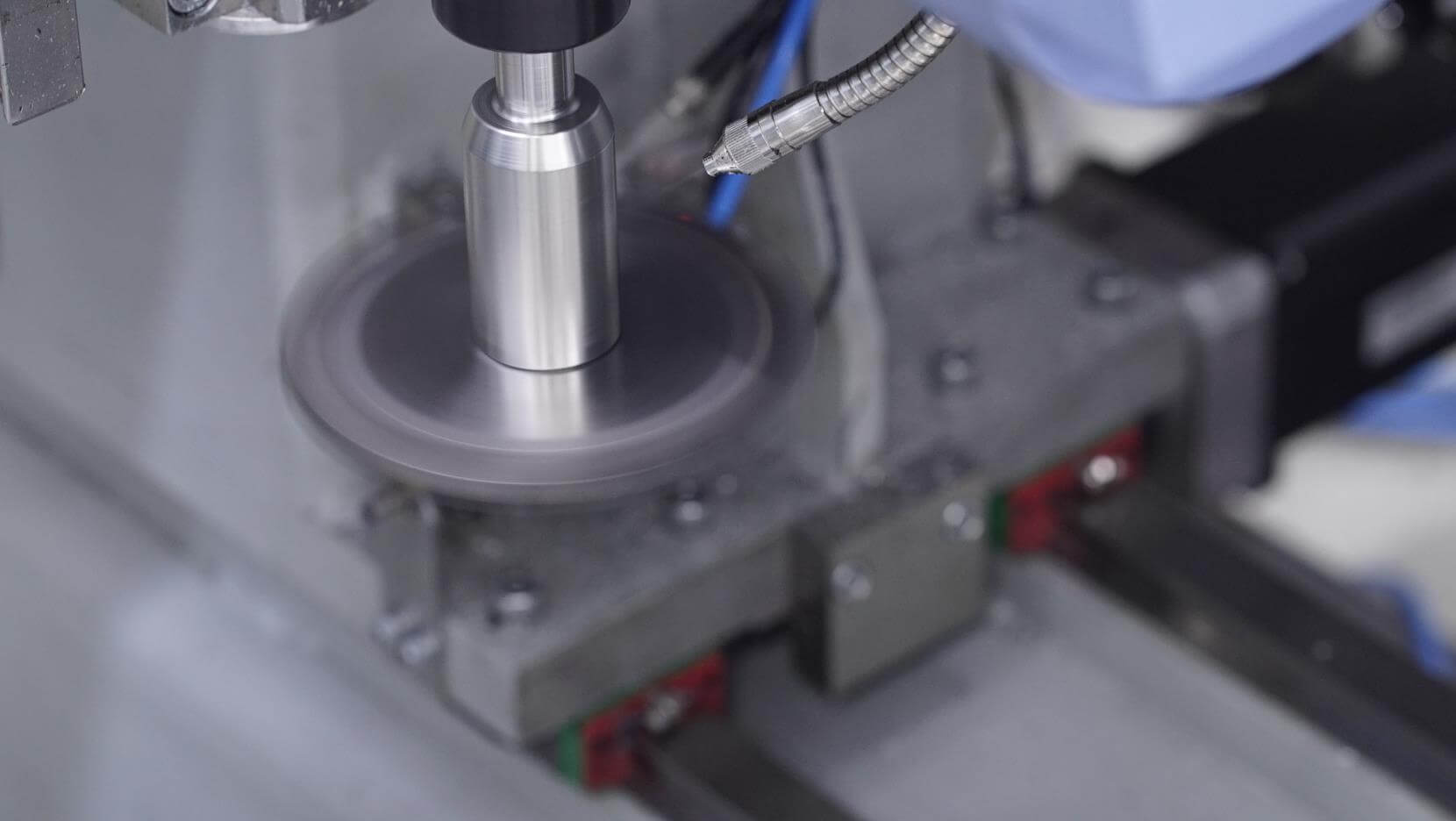

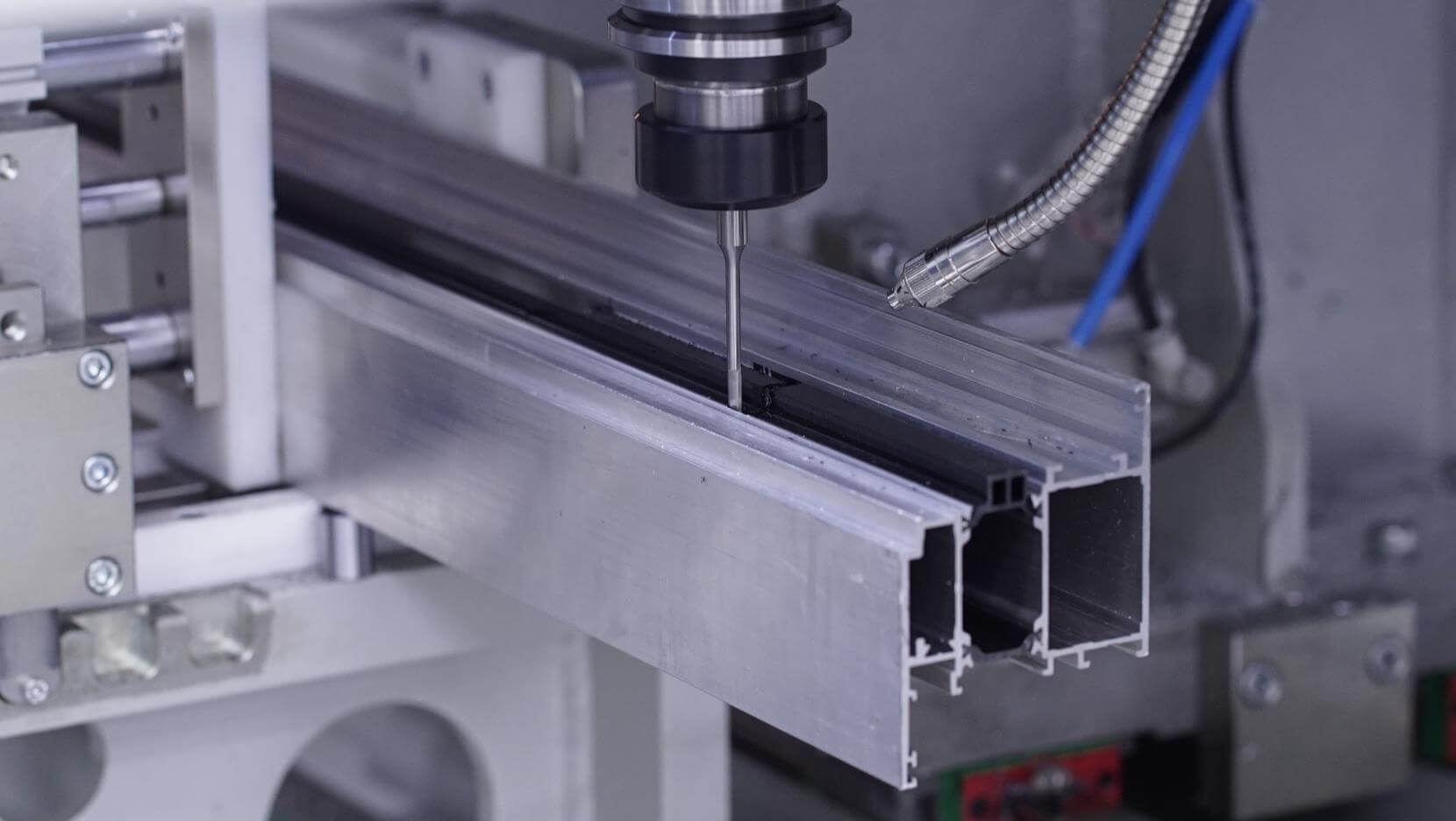

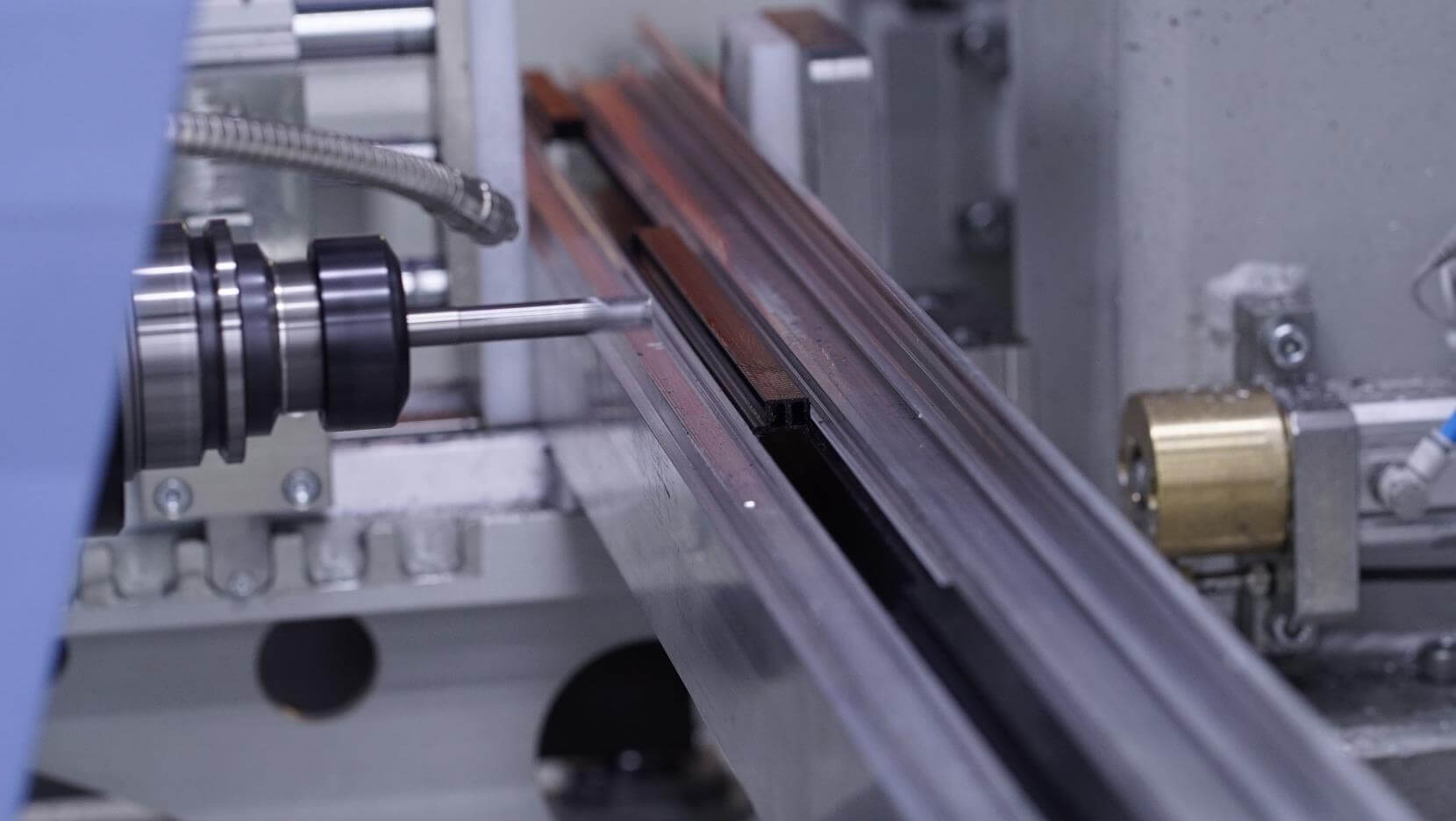

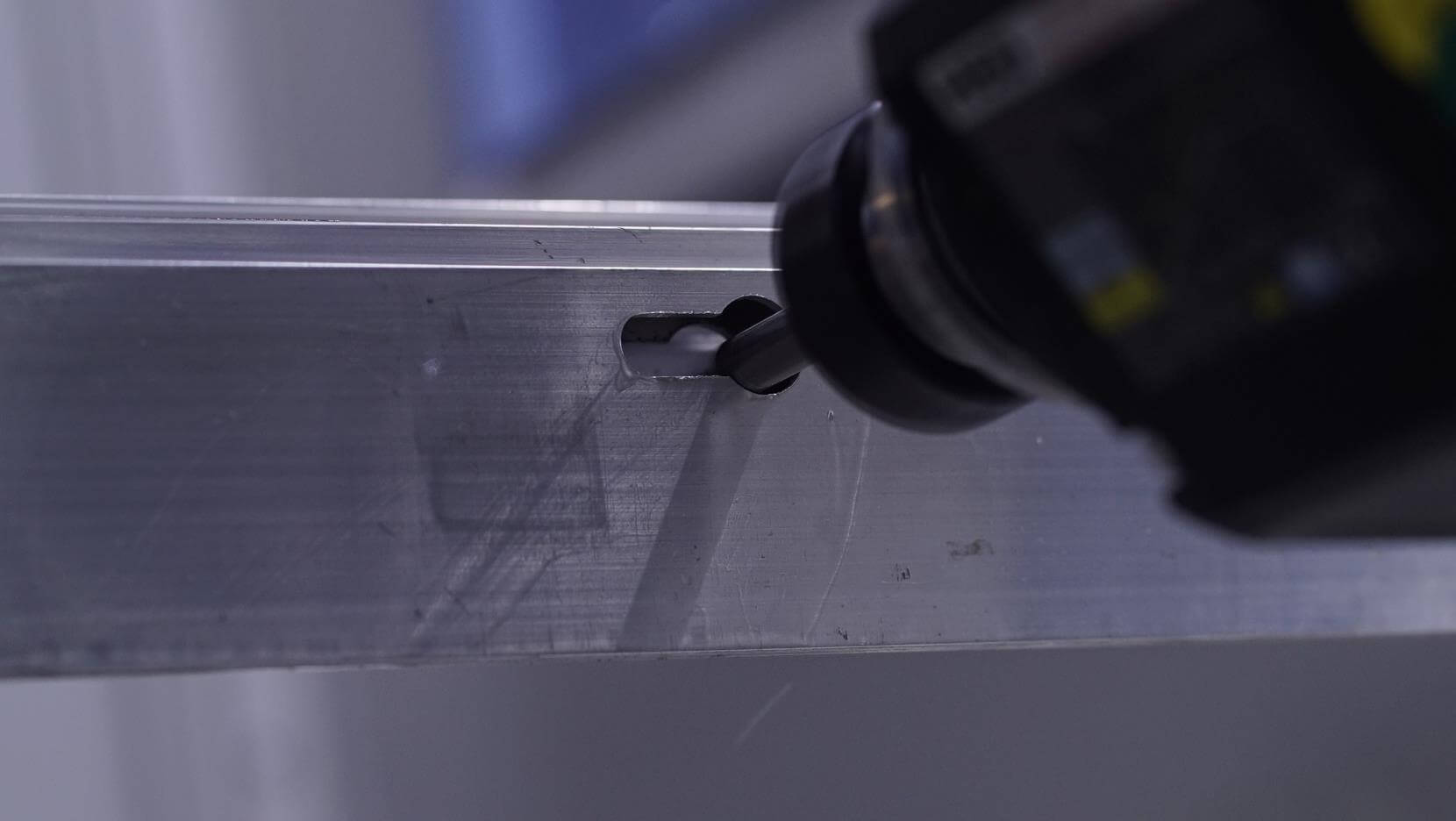

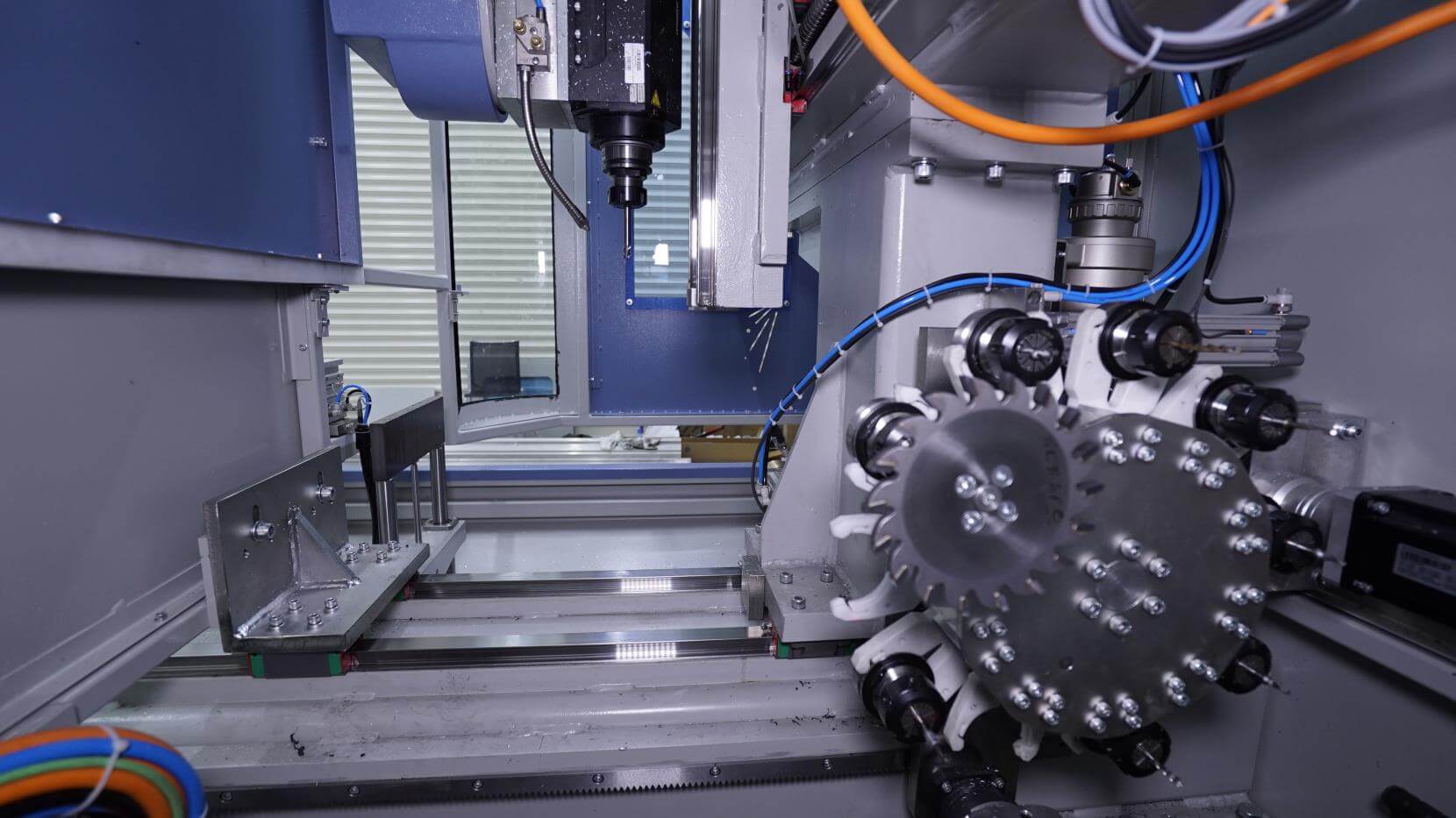

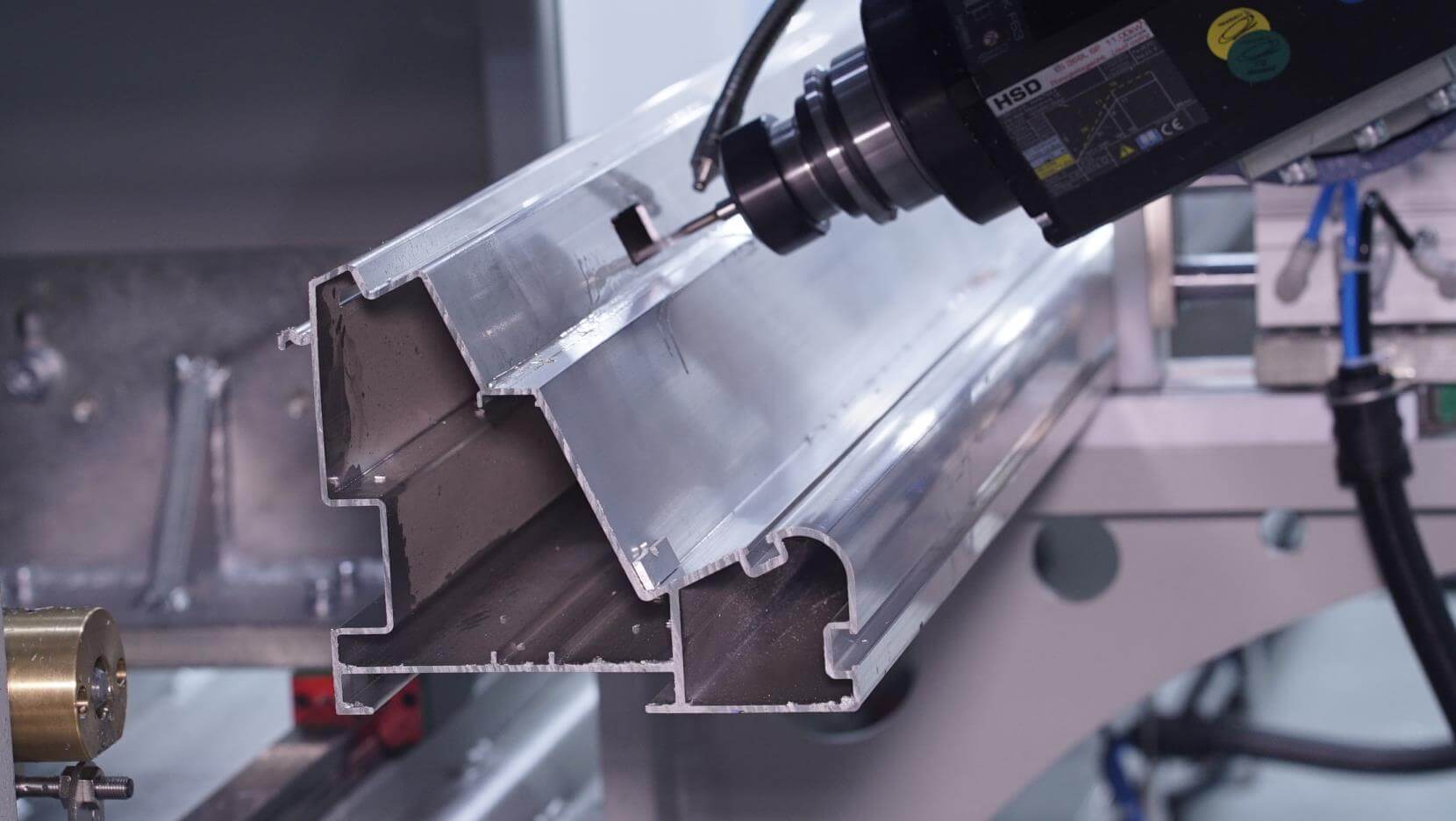

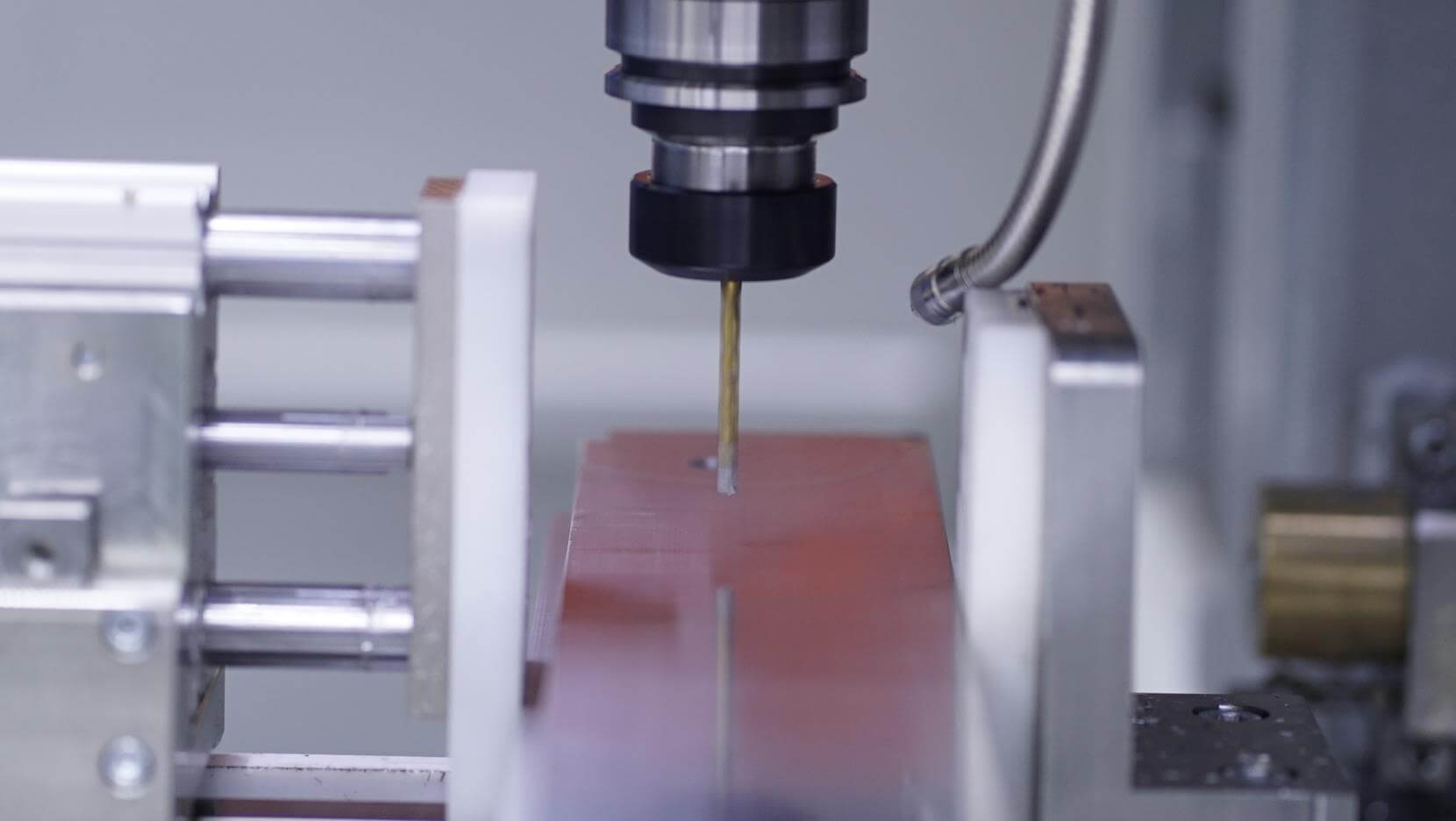

Le centre d’usinage MAC-440 est conçu pour effectuer des opérations standard sur des profilés tels que le fraisage, le perçage, l’entaillage et le marquage, le flowdrill et le taraudage, avec contrôle par ordinateur. Les opérations effectuées sur plus d’une machine de découpe sont rassemblées dans une seule machine, garantissant la vitesse de production et la standardisation de la qualité, tandis que les ressources en main-d’œuvre sont optimisées.

Overview

- The 4-Axis movement is controlled by high-precision servomotors

- 4.1 meters (161.41 in.) of machinable length

- Water-cooled electric spindle (8 kW, (10.72 hp), 24,000 rpm), with HSK-F63 tool connection suitable for material removal processes during milling and drilling operations

- Mobile tool magazine holding up to 6 tools (10 optional) reduces the automatic tool changing time (tools not included)

- Automatic clamp recognition and clamp positioning

- A-Axis processing between -120° to +120°.

- Windows operating system

- 19” LED display screen

- Hand held operator terminal with start/stop switch and speed control

- Pulse spray mist tool lubricant system

- Photoelectric barrier along the front and safety fences along the left and right sides of the machine

- Network connection for remote technical support

- Chip collection trays

- Protective safety cover around machining spindle

- Filter-Regulator-Lubricator for incoming air supply

- Tool kit

- Operating and maintenance manual

- Machine installation and training

Available Options

- Additional pneumatic clamps (without profile support fixtures)

- Two-workstation clamping system

- Automatic independent clamp movement

- 8.5 m (334.64 in.) machining length

- Barcode scanner

- 11 kW (14.75 hp) spindle motor

Video Demo & Application

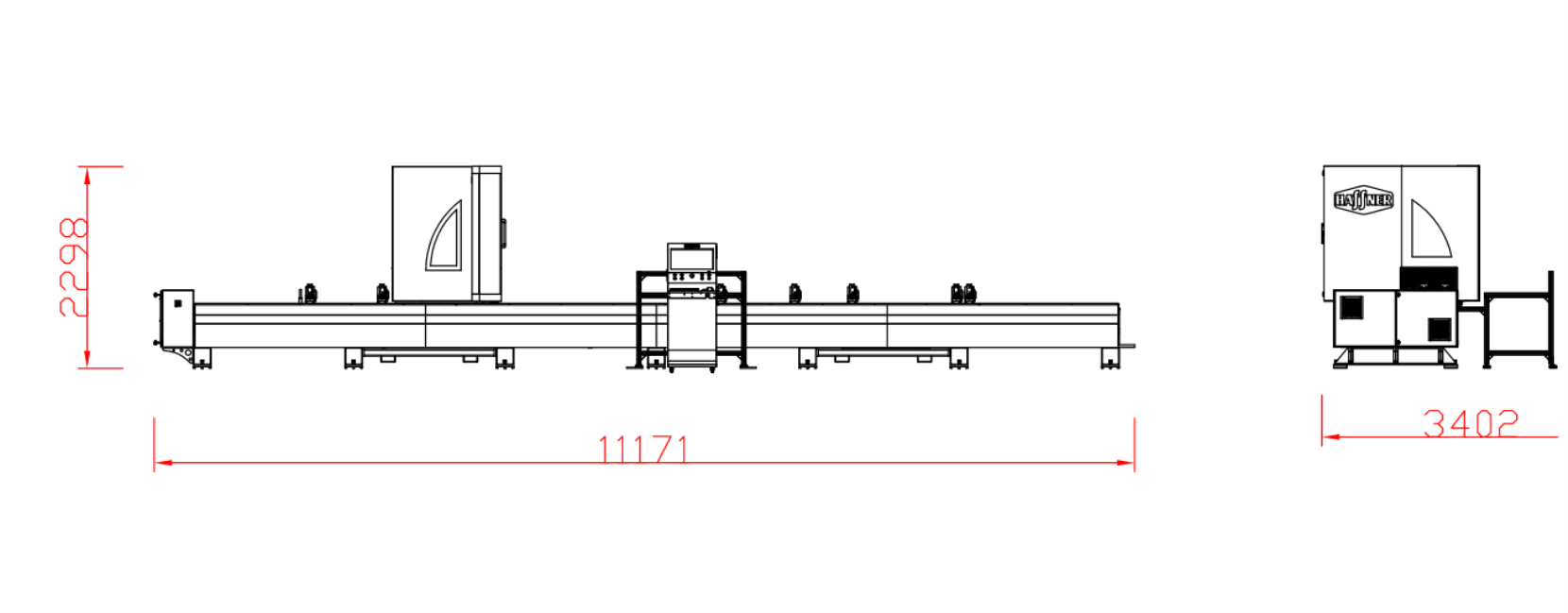

Specs & Sizing

4.1 meter (161.41 in.) Machine

8.5 meter (334.64 in.) Machine

X-Axis traverse path:

4,600 mm (181.10 in.) Vmax. = 120 m/min. (393.70 ft./min.)

9,350 mm (368.11 in.) Vmax. = 120 m/min. (393.70 ft./min.)

Y-Axis traverse path:

930 mm (36.61 in.) Vmax. = 60 m/min. (196.85 ft./min.)

930 mm (36.61 in.) Vmax. = 60 m/min. (196.85 ft./min.)

Z-Axis traverse path:

625 mm (24.60 in.) Vmax. = 60 m/min. (196.85 ft./min.)

625 mm (24.60 in.) Vmax. = 60 m/min. (196.85 ft./min.)

Maximum machinable length:

4,100 mm (161.41 in.)

8,500 mm (334.64 in.)

Tool magazine:

6 positions (10 positions available)

6 positions (10 positions available)

Maximum milling blade diameter:

150 mm (5.90 in.)

150 mm (5.90 in.)

Number of standard pneumatic clamps:

4 pcs.

8 pcs.

Clamp positioning:

Automatic Movement by Machine Head

Automatic Movement by Machine Head

Number of reference stops:

2 Pneumatic

2 Pneumatic

Power supply:

240, 400, 480 or 575V, 3 ph., 50/60 Hz

240, 400, 480 or 575V, 3 ph., 50/60 Hz

Spindle motor power:

8 kW (10.72 hp) (11 kW (14.75 hp) available

8 kW (10.72 hp) (11 kW (14.75 hp) available

Adjustable electro spindle motor:

0 – 24,000 rpm

0 – 24,000 rpm

Tool holder:

HSK-F63

HSK-F63

Working air pressure:

7 bar (100 psi)

7 bar (100 psi)

Connected load:

12 kW

12 kW

Machine height:

2,300 mm (90.55 in.)

2,300 mm (90.55 in.)

Machine length:

6,200 mm (244.09 in.)

11,100 mm (437.00 in.)

Machine width:

1,800 mm (70.86 in.)

1,800 mm (70.86 in.)

Gallery