Inside Fenestration: July Highlights from Haffner Machinery

Blog Post

This month, we explored how smart machinery and proactive strategies are reshaping the production floor, from precision cutting to preventive maintenance. If you’re looking to streamline your screen assembly line or future-proof your operations, Haffner’s latest innovations deliver speed, consistency, and control just for that.

Solving the Production Puzzle with AUTOSCREEN™

Every production floor presents its own unique challenges. Haffner Machinery’s AUTOSCREEN solutions are designed to help manufacturers solve those challenges with precision and efficiency.

Key Components of the System:

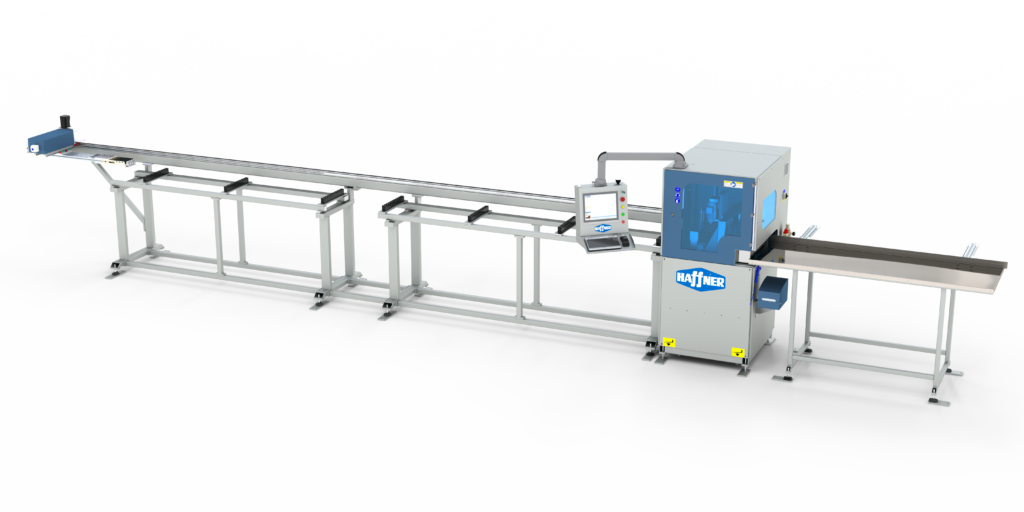

- TA-144/50 Aluminum Wedge Cutting Saw

High-precision, high-volume cutting of aluminum profiles with a 600mm saw blade and 90° angle. Offers a wide cutting range to start your process strong. - SAC-100 Automated Screen Frame Assembly Machine

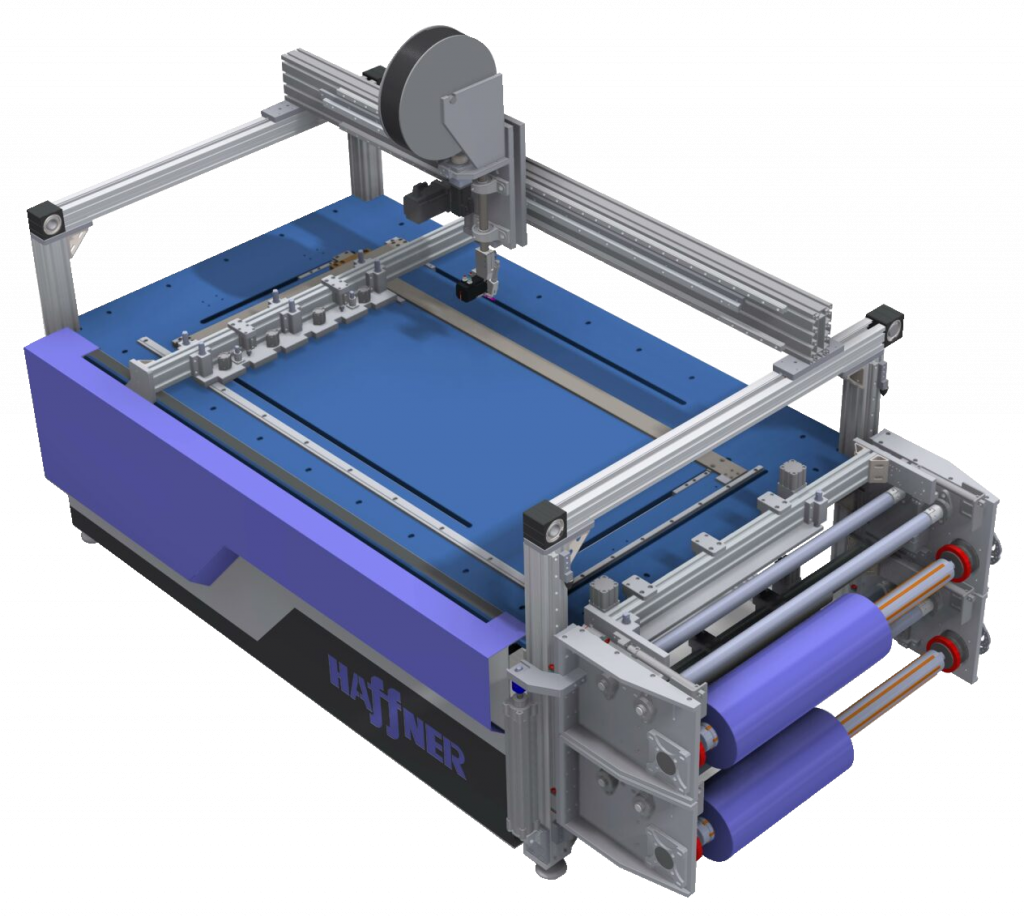

Ensures perfectly welded frames with barcode input, a corner key cartridge system, and a conveyorized design to move frames seamlessly to the next station. - SAC-850 Mesh and Spline Insertion Machine

Processes a 48″ x 60″ screen frame in just 50 seconds. One operator can produce up to 480 screens in an 8-hour shift, bringing the entire system together.

Together, these machines form a complete solution that helps manufacturers tackle daily production challenges with confidence and control.

Reactive vs. Proactive: Why Preventive Maintenance Pays Off

A breakdown doesn’t knock. It crashes loudly, messily, and expensively. And when it does, it halts production, delays orders, and chips away at your reputation.

Every hour invested in Preventive Maintenance saves you days of downtime—and money.

A single worn-out component can bring your entire line to a standstill or even cause irreversible damage. That’s why Haffner Preventive Maintenance Services is a competitive strategy.

What You Gain with Haffner Preventive Maintenance:

- Early detection of hidden issues through structured inspections

- High uptime via system diagnostics, cycle checks, and precision tuning

- Extended machine lifespan with proper alignment and wear inspections

- Critical part replacement based on machine hours—not post-failure

- Improved safety with E-stop, guard, and interlock reviews

- Actionable insights from detailed reports and expert advice

Reactive maintenance might feel cheaper in the moment, but it’s a high-stakes gamble. Preventive maintenance helps you win the battle before it begins.

Ready to Transform Your Production Line?

Whether you’re solving the daily puzzle of screen assembly, leveling up with precision machining, or protecting your uptime with preventive maintenance, Haffner Machinery is here to help you move faster, smarter, and more confidently.

Let’s connect and build your next move.

Call 1.888.423.3671 or connect with us today.

Product Features

TA-144/50: Start Strong with Precision Cutting

Every productive day starts with a great cup of coffee: warm, reliable, and energizing. Now imagine your production line starting the same way.

Meet the TA-144/50 Automatic Aluminum Wedge Cutting Saw, the first step in Haffner’s powerful AUTOSCREEN trio. It’s the machine that brings that “first-cup” energy to your fabrication floor.

Why It Sets the Tone:

- Precision-ground carbide blades deliver clean, accurate wedge cuts—no warm-up needed.

- Fully automatic operation means your team can hit the ground running with minimal setup.

- Adjustable cutting angles offer flexibility without slowing you down.

- High-volume capacity keeps your workflow energized from open to close.

As the foundation of the AUTOSCREEN system, the TA-144/50 ensures your screen frame production starts with speed, consistency, and control.

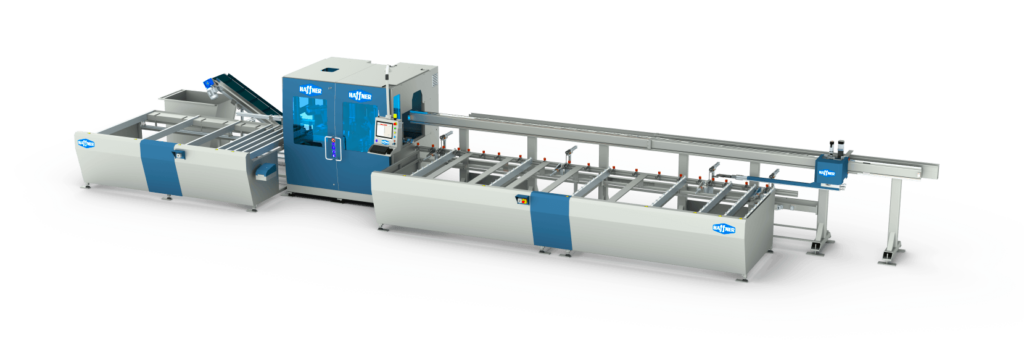

DMC-052: Precision That Plays to Win

If your production floor feels like a game of Tetris: stacking parts, scrambling to deliver, and hoping everything lines up before time runs out. Haffner Machinery has your cheat code.

Introducing the DMC-052 PVC Profile Machining Center code:

One machine + One operator + One shift = 80 Patio Door Sets

Key Features:

- Handles all operations: cutting, milling, drilling, dimpling

- Processes with precision and repeatability

- Eliminates bottlenecks and micro-delays

- Maximizes labor efficiency and ROI

No more shuffling parts or rotating components to “make them fit.” The DMC-052 brings control and clarity to your workflow, helping you level up your output without the stress.

SAC-850: Precision Engineered for Screen Automation

The latest upgrade to the AUTOSCREEN trio, the SAC-850, is more than a machine. It’s a precision instrument designed to automate mesh and spline insertion with near-clinical accuracy. Think of it as your assistant for screen production: fast, flawless, and tireless.

Why It’s Revolutionary:

- Automates mesh and spline insertion with unmatched precision

- Eliminates manual bottlenecks, freeing your team for higher-value tasks

- Accelerates production without compromising quality

This isn’t just automation; it’s engineering with intent.

In today’s competitive landscape, efficiency isn’t optional; it’s essential. The SAC-850 gives you the edge by combining speed, accuracy, and reliability in one sleek system. It’s not just a tool — it’s your new production partner.

Meet Us at GlassBuild America 2025 – Booth #21097

We’re excited to invite you to join us at GlassBuild America, happening November 4–6 in Orlando, FL.

Stop by Booth #21097 for a personalized tour of the latest innovations shaping the fenestration industry. From automation breakthroughs to precision engineering, we’ll show you how Haffner Machinery is helping manufacturers level up their production lines.

Use code ORL25 for complimentary entry passes.

Let’s connect, explore what’s new, and talk about how we can support your goals.