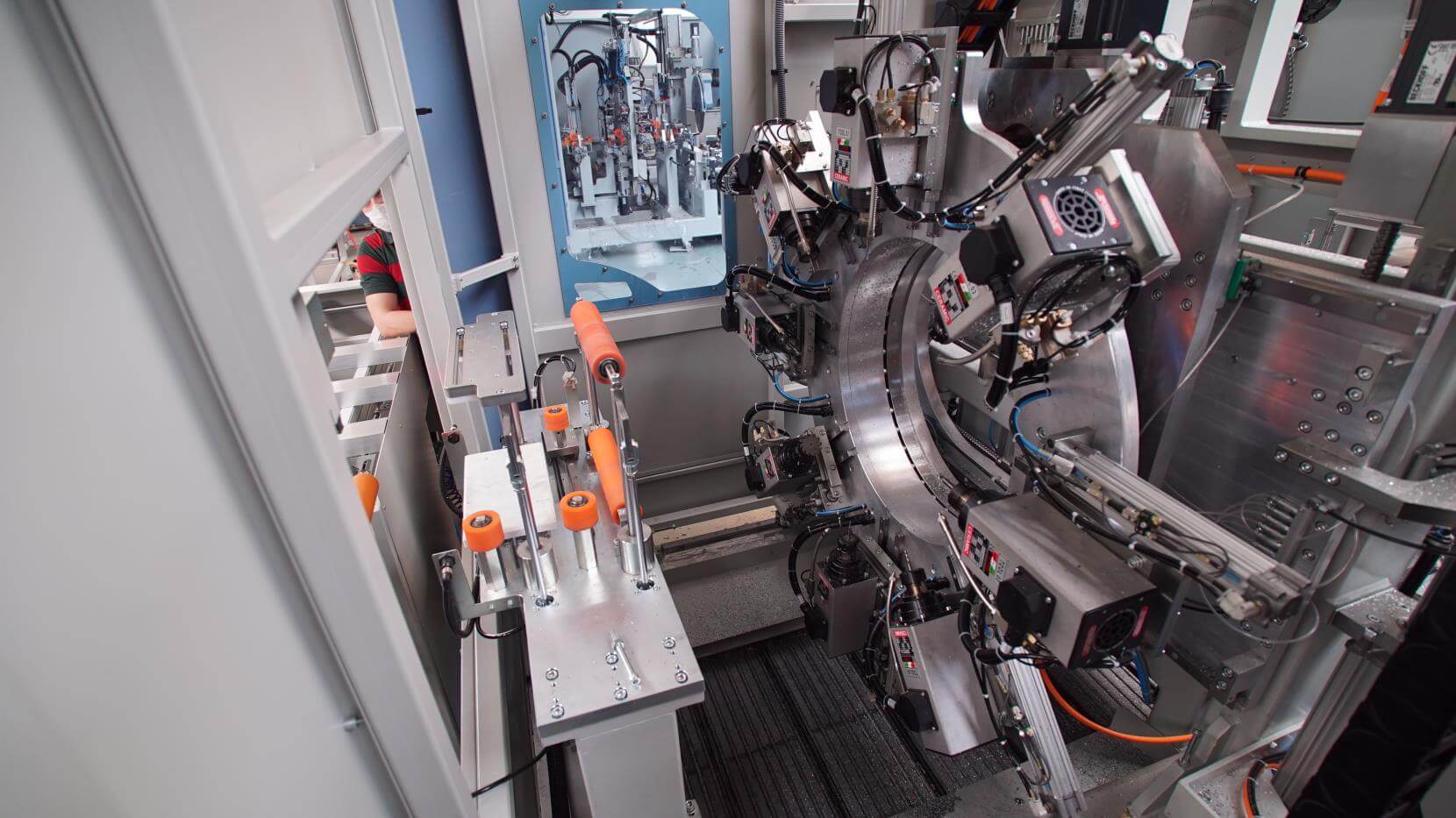

AL-230 Aluminum Profile Processing Center

AL-230

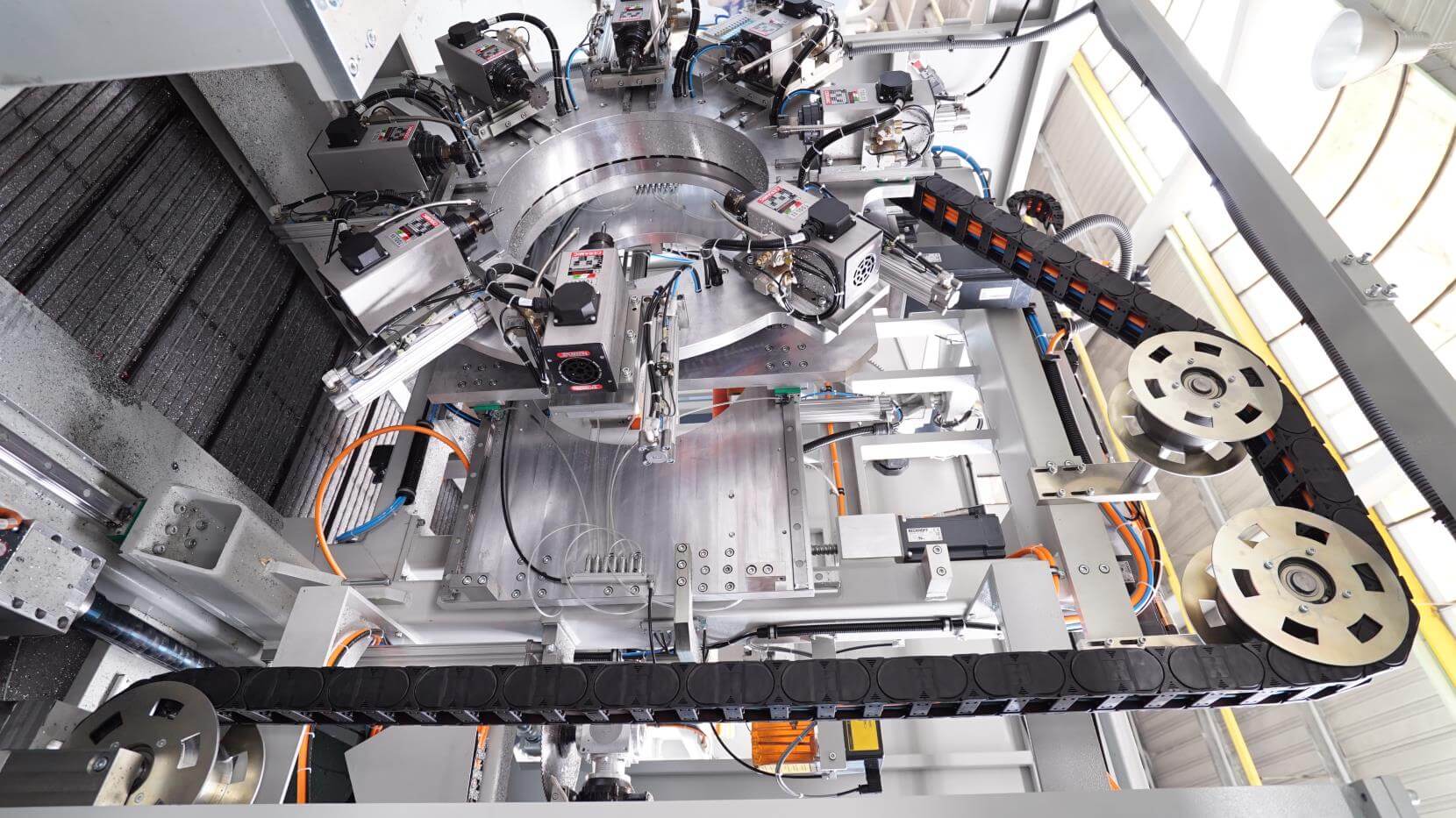

AL-230 Profile Machining Center is designed to carry out all cutting, milling, drilling, marking, centering and face milling operations on aluminum profiles in a computer-controlled, single machine. The operations performed on more than one cutting machine are collected in a single machine, ensuring production speed and quality standardization, and reducing labour cost.

Overview

- All cutting, notching, milling, drilling and marking operations on the aluminum profiles have been pieced together in a single, computer-controlled machine

- 7 profile stacking capability (maximum profile length: 7.5 m (295.27 in.))

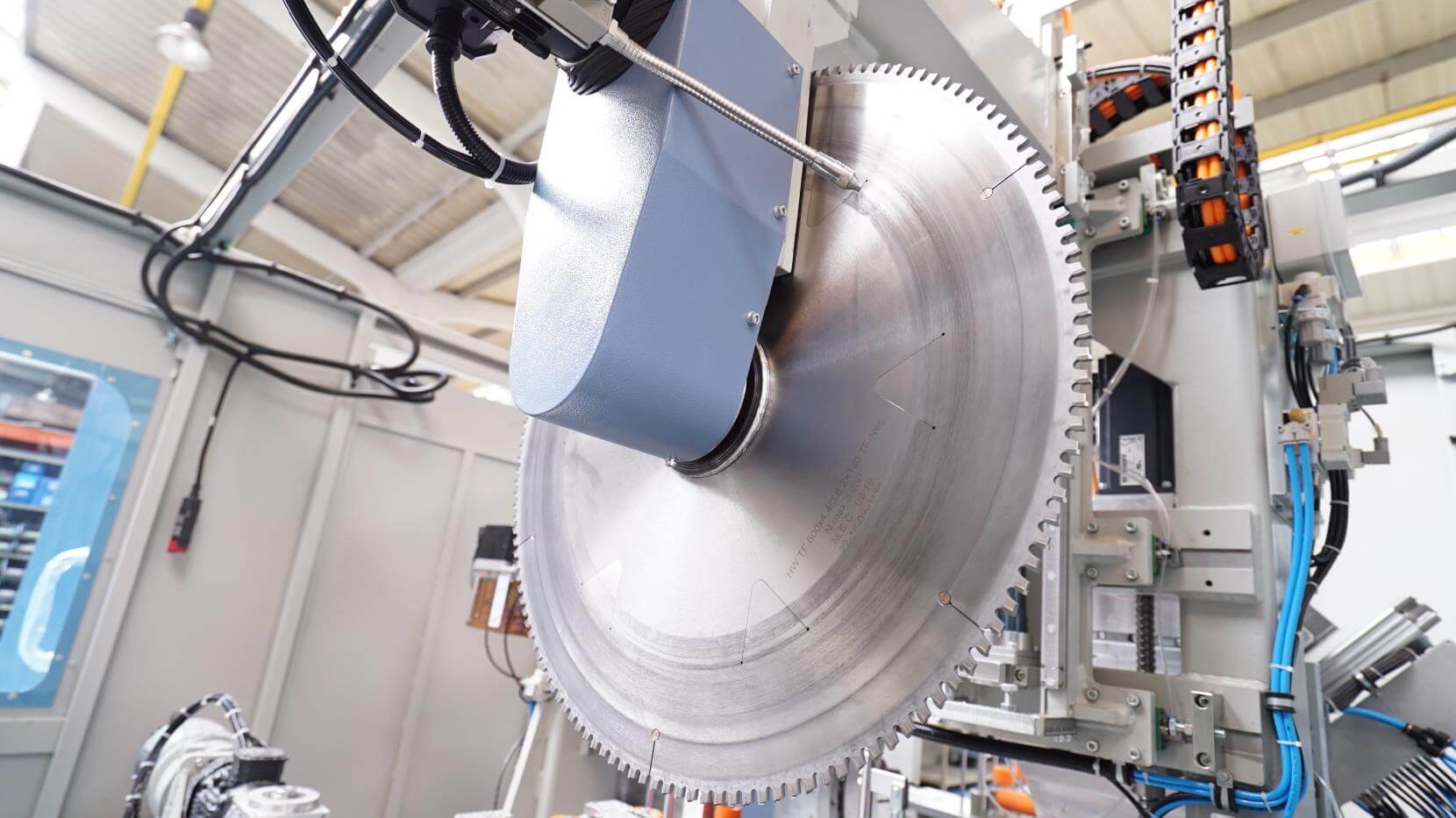

- Servo motors allow automatic vertical sawing at all angles between 0° and 360° in 0.1° increments (600 mm (23.62 in.) diameter blade)

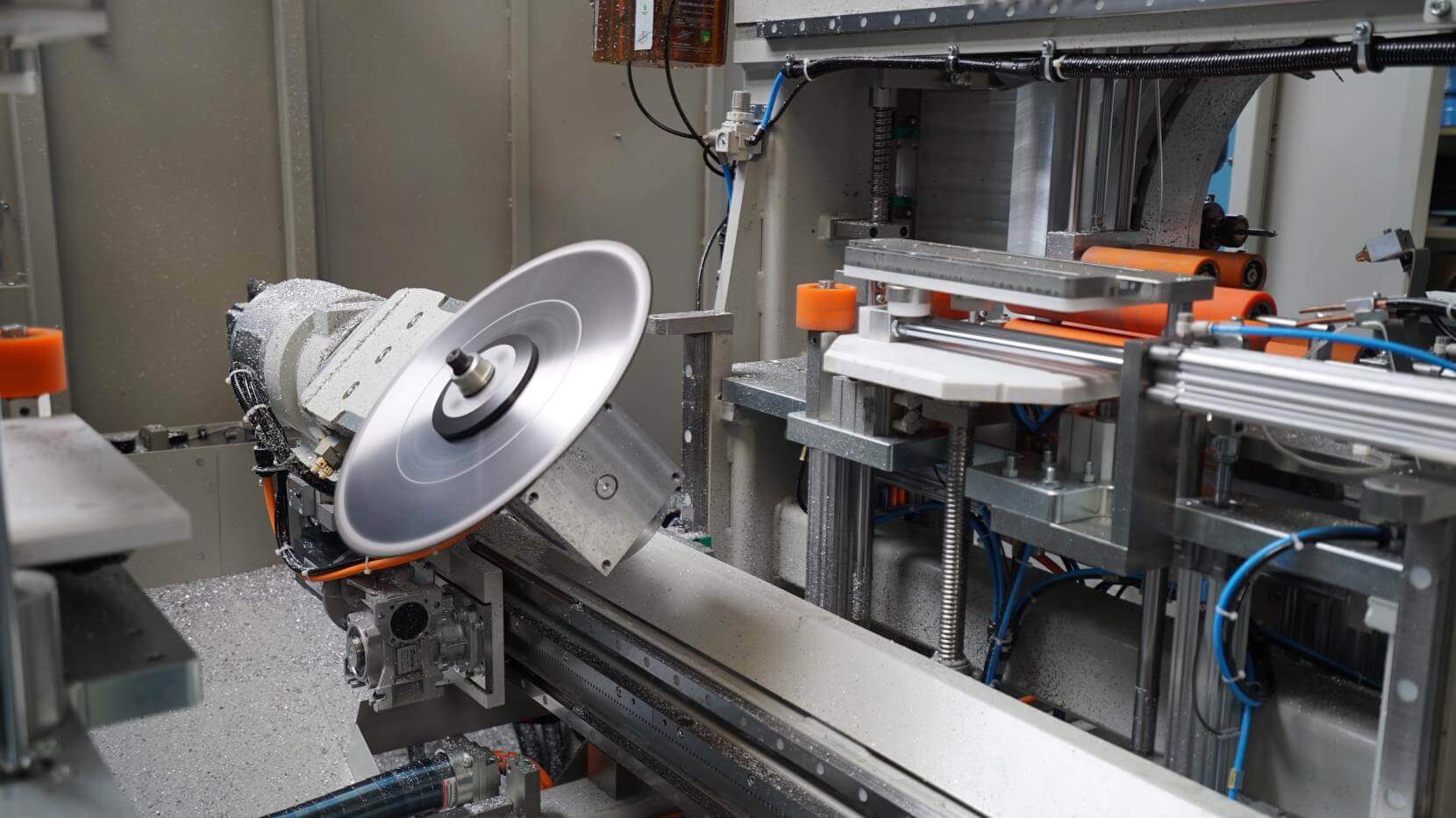

- Servo motors allow automatic horizontal sawing at all angles between 45° and 135° in 0.1° increments (400 mm (15.74 in.) diameter blade)

- Able to work with high speed and sensitivity due to 15 axes controlled by servo motors

- 0°-360° rotatable servo controlled gripper

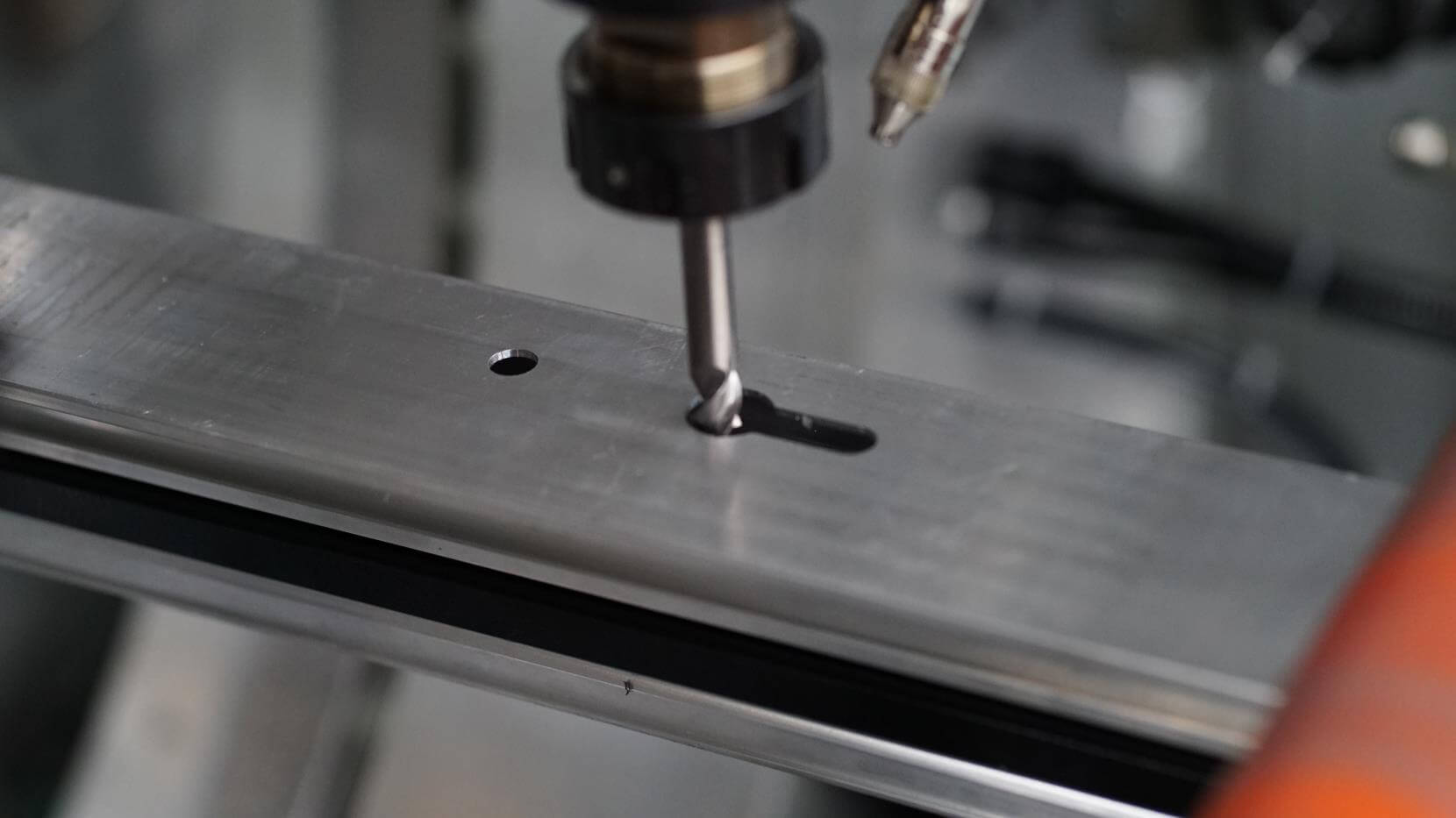

- Performs opening, drilling and milling operations of angled water drainage channels

- Carries remaining waste parts to the waste chamber with an automatic conveyor system

- Performs all operations sensitively with 8 tool set being standard in the rotary milling group

- 15.6” touch screen

- High performance industrial PC Windows, working between 0° – 55°C (32° – 131°F) without an additional fan

- Works with production data coming from different window production software giving minimum waste

- All error messages can be monitored from the screen

- Provides service and troubleshooting with remote connection method

- Operating system ensures maximum safety measures against virus spreading and user errors by cleaning unnecessary processes of the last login automatically at every opening/closing of the machine

- Remote network connection or data transfer via USB

- Possibility to perform daily backup operation to internal back up unit automatically

- Daily, weekly, monthly and annually production control with shift control system

AVAILABLE OPTIONS

- Servo controlled 3-axis end milling unit

- Circular Saw Blades

- Tool Holders

- Infeed and Outfeed Material Extensions

Video Demo & Application

Specs & Sizing – Cutting Unit

Vertical cutting saw blade diameter: 600 mm (23.62 in.)

Horizontal cutting saw blade diameter: 400 mm (15.74 in.)

X-axis travel (vertical saw): 425 mm (16.73 in.)

Y-axis travel (vertical saw): 950 mm (37.40 in.)

Z-axis travel (vertical saw): 600 mm (23.62 in.)

Y-axis travel (horizontal saw): 880 mm (34.64 in.)

Z-axis travel (horizontal saw): 300 mm (11.81 in.)

Profile processing width: 30-300 mm (1.18-11.81 in.)

Profile processing height: 30-230 mm (1.18-9.05 in.)

Profile cutting length: 300-7,500 mm (11.81-295.27 in.)

Bar length: 1,200-7,500 mm (47.24-295.27 in.)

Bar loading system (pcs.): 7

Machine length: 18,200 mm (716.53 in.)

Machine width: 4,900 mm (192.91 in.)

Machine height: 2,730 mm (107.48 in.)

Machine weight: 8,500 kg (18,740 lbs.)

Angle range of vertical cutting-off machine: 0° to 360°

Angle range of horizontal cutting-off machine: 45° to 135°

Blade motor power of vertical cutting-off machine: 3 kW (4.02 hp.)

Blade motor power of horizontal cutting-off machine: 1.5 kW (2.01 hp.)

Specs & Sizing – Milling Unit

X-axis travel: 425 mm (16.73 in.)

Y-axis travel: 470 mm (18.50 in.)

Z-axis travel: 325 mm (12.79 in.)

C-axis travel (rotary base rotation): 0° – 315°

Number of spindle motors: 8

Maximum spindle power in S1: 4.5 kW (6.03 hp.)

Maximum spindle speed: 18,000 rpm

Tool connection: ER 32

Gallery