In modern manufacturing, efficiency is needed for higher yields and throughput. Haffner’s HMU: Haffner Machine Utilization app was created to give manufacturers visibility into machine performance for all of Haffner’s advanced fenestration machinery. Haffner also offers a separate VDoD: Video on Demand Camera Monitoring system that operates independently from the HMU app, ensuring that monitoring and utilization tracking are both analyzed for optimal functionality.

From real-time monitoring to historical data analysis, HMU helps supervisors and operators make informed decisions that drive productivity. We recently sat down with Laura A., a systems integration specialist and software engineer at Haffner Machinery, to discuss how this tool is reshaping operations for Haffner customers.

Q&A with Laura A.

What is the HMU app, and why was it developed?

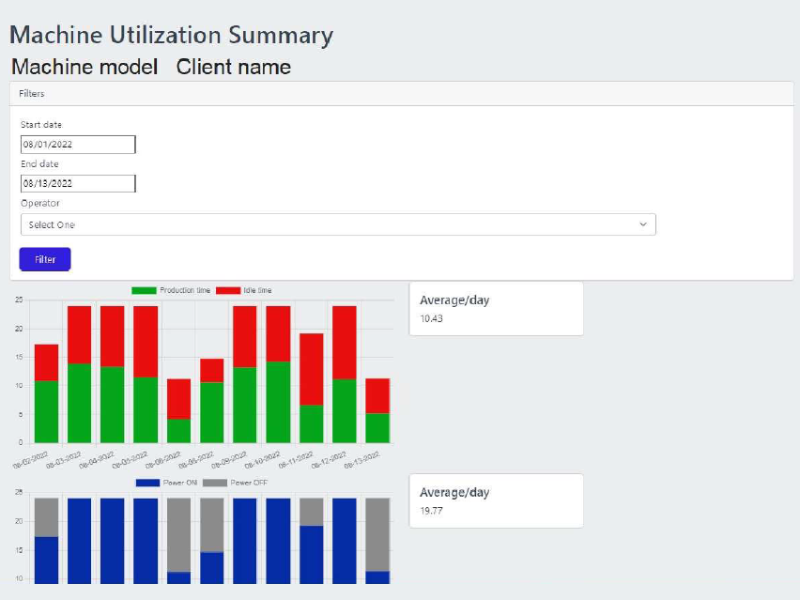

The HMU app is a web-based platform designed to track and analyze machine utilization. Before HMU, clients could only view live camera feeds to confirm if machines were running, but they lacked historical data to understand trends or diagnose issues. HMU fills that gap by recording when machines are working and any issues with their processes.

This visibility helps identify bottlenecks, reduce downtime, and ensure machines deliver the ROI promised at purchase.

How does HMU help improve a manufacturer’s productivity?

By making machine usage transparent, HMU empowers supervisors to spot inefficiencies quickly. For example, if a machine is idle during peak production hours, the app highlights this gap, prompting corrective action.

One client significantly increased machine utilization after adopting HMU because they could pinpoint underuse and adjust workflows. Over time, this translates into higher output, reduced labor costs, and better alignment with production goals.

How does HMU differ from traditional monitoring tools?

Generic monitoring systems often require multiple integrations. However, HMU is integrated into all Haffner machines. This means fewer technical hurdles and faster data updates.

Users can log in from any internet-enabled device, including smartphones, PCs, and tablets, making machine status checks available anywhere you have internet connection.

Traditional tools also often provide fragmented data. HMU consolidates everything in one easy-to-use interface to reduce complexity and improve decision-making speed.

Want to learn how predictive monitoring with HMU can help boost productivity for your production line? Read our blog, “Predictive Maintenance: Driving Reliability and Growth in Smart Manufacturing.”

What kind of data does HMU track?

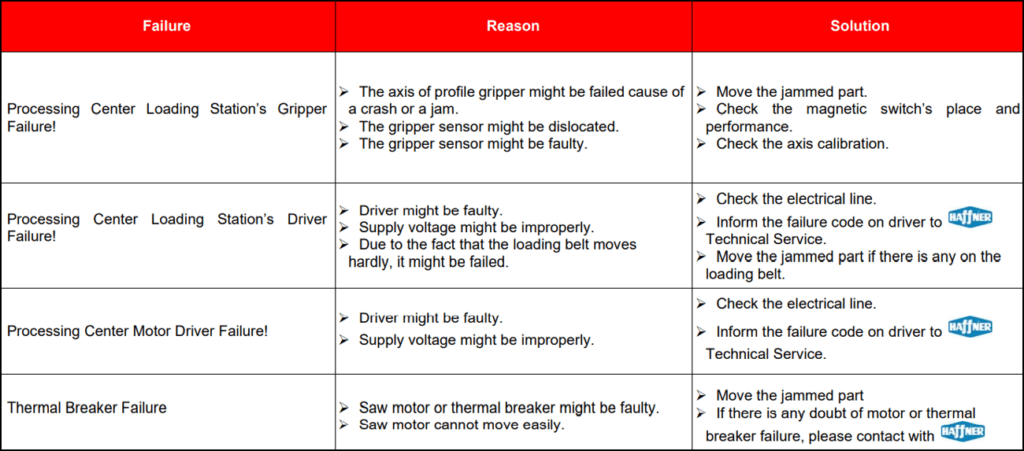

Currently, HMU captures four key metrics:

- Working time – How long the machine actively produces.

- Power on/off – When the machine starts and stops.

- Idle time – Periods of inactivity that can signal inefficiencies.

Future updates will add data on machine alerts, operator tracking, and downloadable reports. These enhancements will allow supervisors to analyze downtime causes and compare planned vs. actual productivity.

Is HMU available for all Haffner machinery?

Yes, HMU can be installed on all Haffner machines. However, Video on Demand Camera Monitoring is typically reserved for larger machines like processing centers and double-track systems, where productivity impact is highest. Smaller machines may not include cameras, but they still benefit from HMU’s data tracking capabilities.

The Haffner team is currently working on integrating live camera feeds with HMU. Soon, users will be able to stream live camera feeds within the HMU portal, combining visual confirmation with performance data for a complete picture of machine health and activity.

How often is HMU updated?

The development team plans around five updates per year. These updates focus on improving speed, adding new utilities like downloadable reports, and enhancing user experience. Clients often contribute ideas, making HMU a tool that evolves with real-world needs.

What is the subscription process?

HMU offers a free trial period, so clients can explore its features before committing. After the trial, an annual subscription provides access for up to five supervisors, who can create operator accounts under their profiles. This structure ensures scalability for teams without overwhelming costs.

Haffner’s HMU app is a strategic asset for manufacturers aiming to optimize efficiency to keep up with the evolving needs of the fenestration industry. By providing real-time and historical data, HMU helps teams make smarter decisions, reduce downtime, and achieve production goals faster.

Ready to transform your operations? Contact us to explore how HMU can unlock your shop’s full potential.