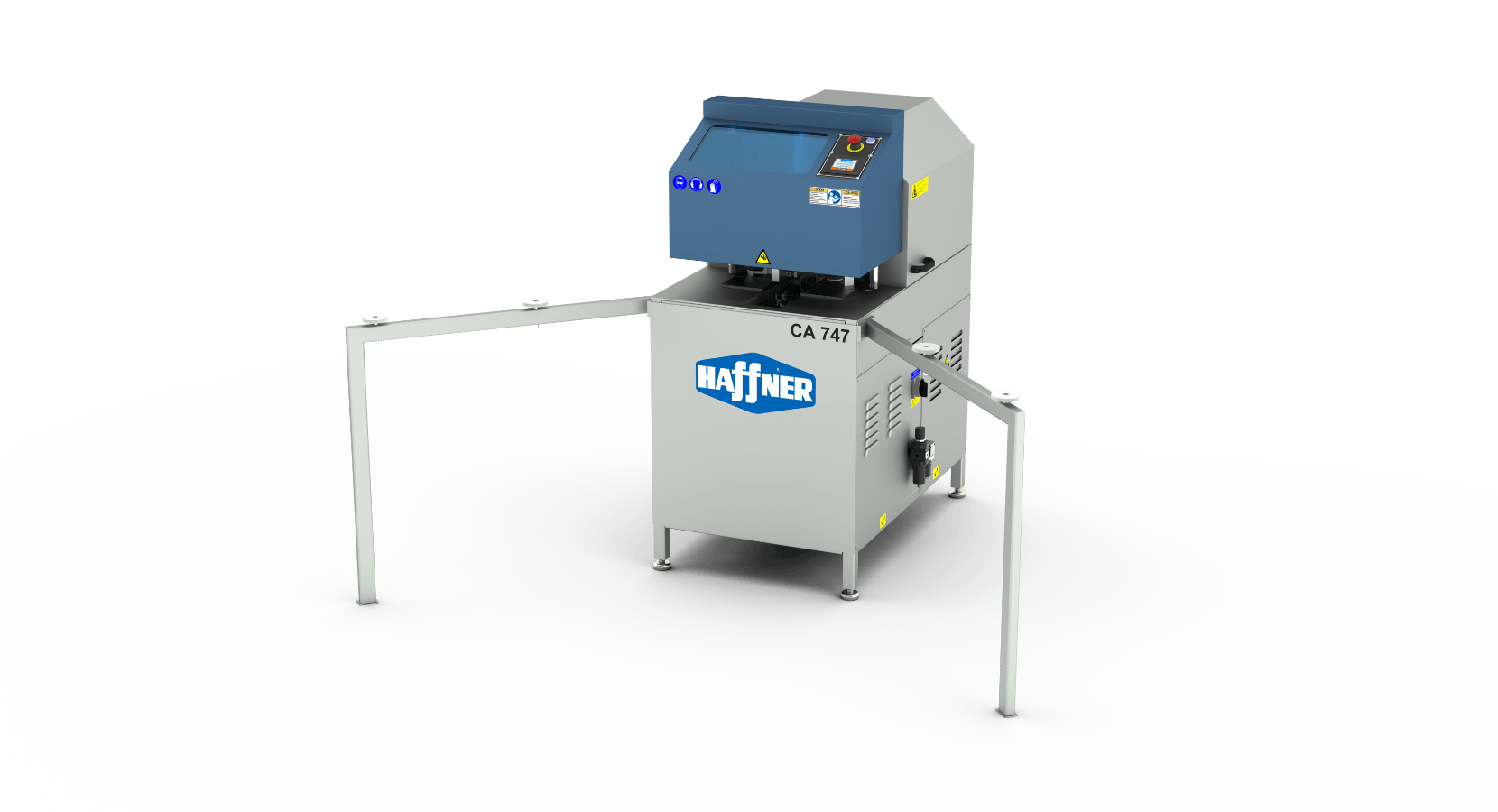

CA-747 Corner Cleaning Machine

CA-747

CA-747 Cleans the welding seam on lower and upper surfaces of welded profiles with grooving knives. It mills the welding seam at the outer corner of the welded profiles with four different set of disk cutters. The system is equipped with full automatic PLC operator. CA-747 automatically identifies case and sash profiles and positions the cleaning blades. All operations are controlled by the digital touch screen display.

Overview

- Cleans the welding seam on lower, upper surfaces of welded profiles with grooving knives

- Mills the welding seam at the outer corners of welded profiles with two different set of disk cutters

- Full automatic PLC operating system

- Automatic identification and cutter set positioning for frame and sash profiles

- Four different cutter sets can be settled.- All operations are controlled by the digital touchscreen display

- Automatic system for pushing the welded profiles to the back fence to provide accurate centering

- Profiles are fixed by horizontal clamps to ensure optimum work piece fixing

- Standard equipped with profile support arms

Video Demo & Application

Specs & Sizing

Operating voltage:

400V, 3ph

400V, 3ph

Frequency:

60 Hz

60 Hz

Total power:

1.5hp

1.1Kw

Spindle speed:

2800 RPM

2800 RPM

Air pressure:

90-120 psi

6-8 Bar

Air consumption:

2.54 CFM

75 Lt/min

Machine length:

30.75 inches (+53.5 inches arms)

780 mm (+1360 mm arms)

Machine width:

42 inches (+25 inches arms)

1075 mm (+630 mm arms)

Machine height:

59 inches

1500 mm

Machine weight:

551 lbs

250 kg

Max. profile width:

4.75 inches

120 mm

Max. profile height:

3.5 inches

90 mm

Max. cutter dimension :

6.3 inches

160 mm

Min. profile height:

1.5 inches

40 mm

Gallery