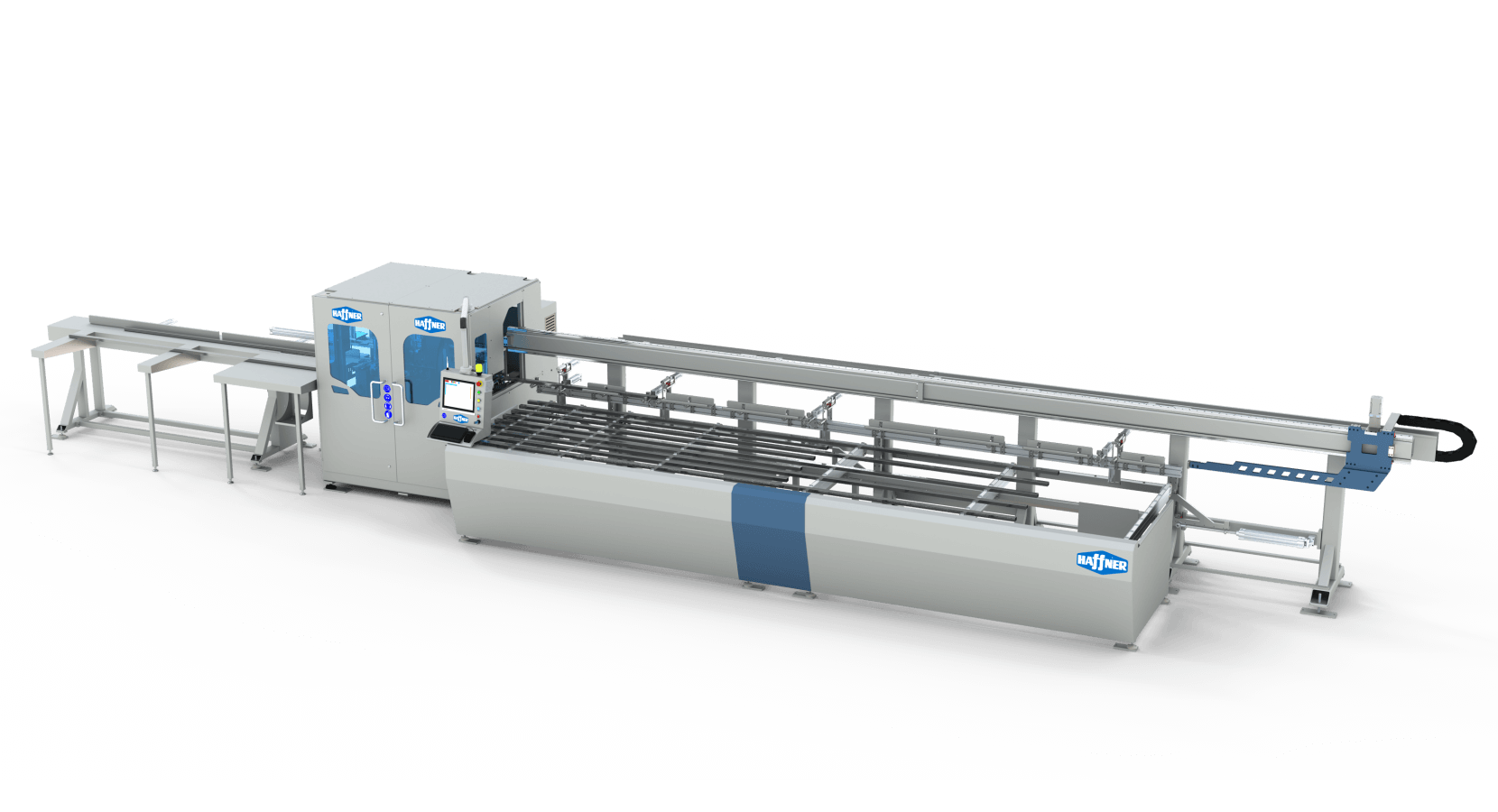

DS-902 Reinforcement Profile Cutting Center

DS-902

DS-902 Plasma Machining Center is designed to perform all cutting, punching and unloading operations on the reinforcement steel used in PVC profiles in a single station, with computer control. In this way, the production speed and quality standardization are ensured, and labor costs have been greatly reduced thanks to the automatic pre-processing of the reinforcement sheets with PVC profiles or manually outside.

Overview

- Advanced industrial CNC 4-axis profile processing centre

- Stacking of 10 profiles (max 6,000 mm length)

- High-tech plasma cutting unit

- Slot opening and hole drilling operation is facilitated by plasma unit and cutting operation is facilitated by punch group on steel reinforcement profiles

- Adopts imported high precision linear bearing system, ball screws, gear racks and servo motor to ensure smooth motion, positioning and processing in high precision

- Problem identification, solution and servicing by means of remote connections

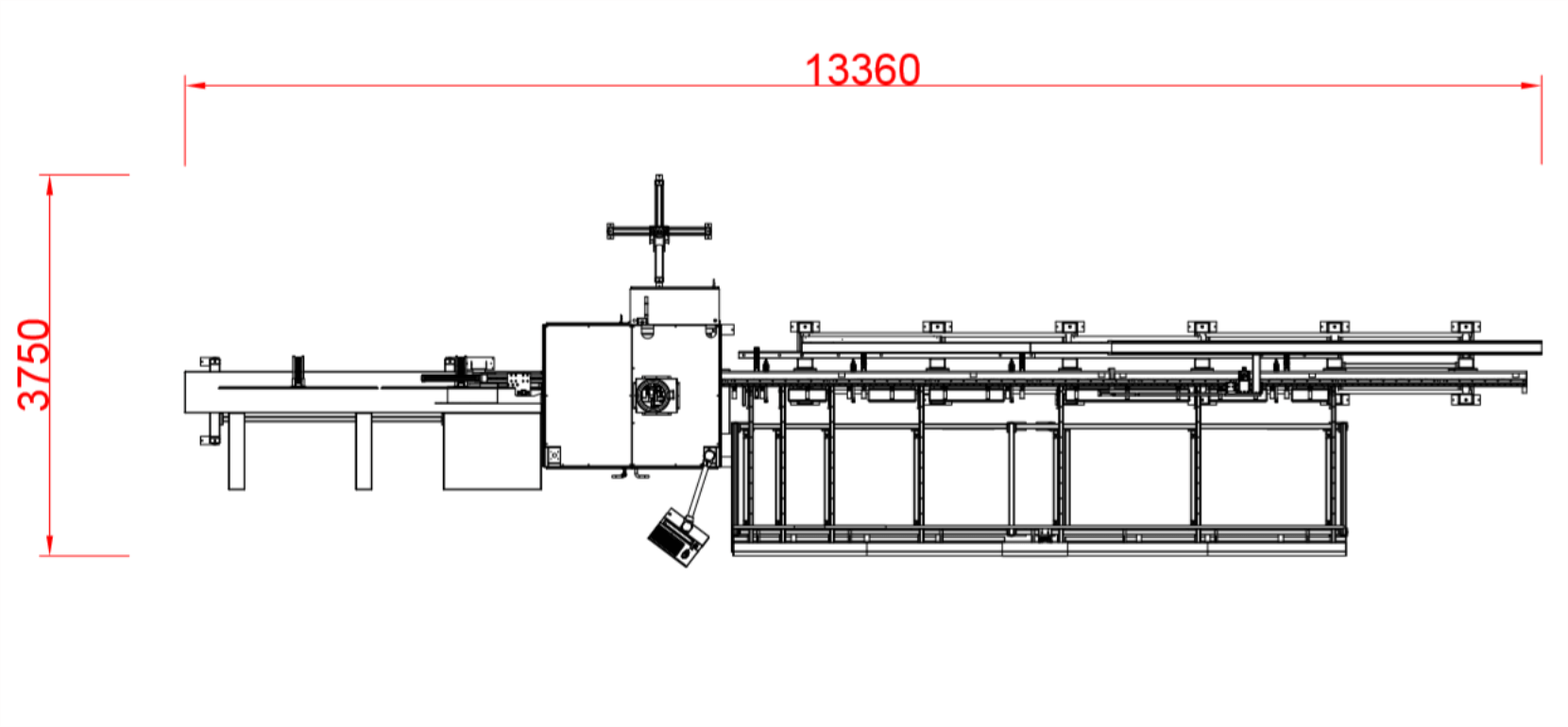

Specs & Sizing

Power Supply: 400V, 50Hz

Power Output: 15kW, 40A

Air Consumption: 300 l/min

Minimum Profile Height: 20mm

Maximum Profile Height: 60 mm

Minimum Profile Width: 20 mm

Maximum Profile Width: 60 mm

Minimum Profile Processing Length: 330 mm

Minimum Row Profile Length: 500 mm

Machine Height: 2150 mm

Machine Length: 13,360 mm

Conveyor Length: 2910 mm

Machine Width: 2645 mm

Machine Weight: 3,750 kg

Gallery