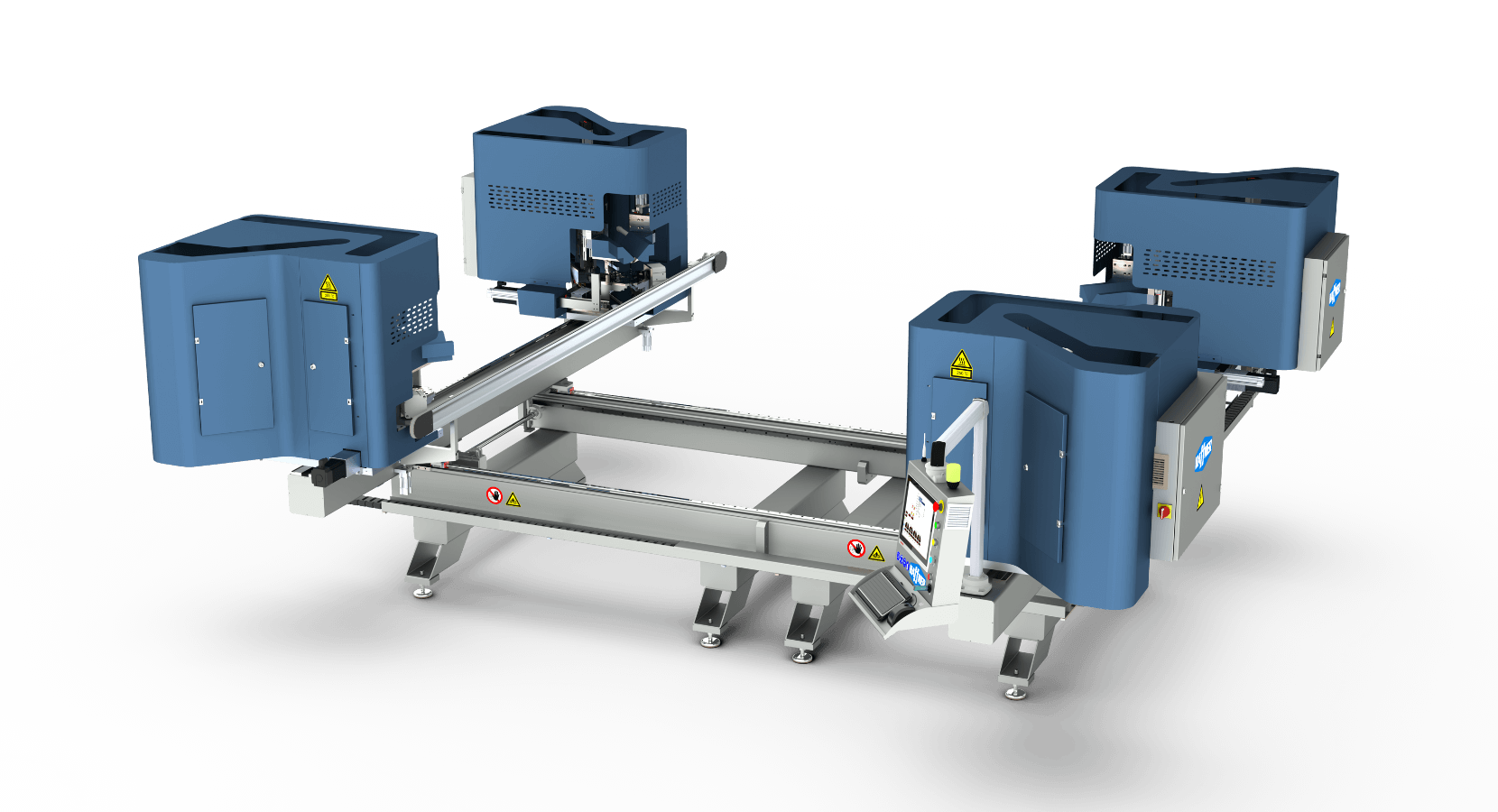

DWM-027 Four Head Welding Machine

DWM-027

DWM-027 Cleans the welding seam with 19 servo-axis on the upper and lower surfaces as well as inner corners of any type of white or colored profile. The software cleans unnecessary processes and sustains maximum security against virus attacks and user faults at every system start-up and turn-off. It creates a database of welding parameters of profiles defined by the user (up to 6,000 parameters). Cleaning of radius and angle inner conners saves time as it reduces the operations left in the CNC corner cleaning machine. All error messages can be monitored from the screen by the software developed by Murat Machinery Software Department.

Overview

- Patented welding method for Aluminium & PVCu profiles

- Welds 4 pieces of profile simultaneously at 90°

- 19 servo driven axis for consistent accuracy

- PLC Controlled (PID) heat control system for strong welds

- Adjustable temperature, welding and cooling time

- Quick change welding blocks

- 15” touch screen with industrial PC

- Windows 10 operating system

- Data transfer via USB, wifi or network connection

- Database of up to 6,000 welding parameters

- Servo motors with precision movement on hardened steel ball-screws

- Measurement controlled system for final size welding parameters

- Central Lubrication system

- Remote detection via Team Viewer

- Shift control system for daily, weekly, monthly reports

AVAILABLE OPTIONS

- Barcode reader (AK 002)

- Welding moulds

Specs & Sizing

Air pressure 6-8 bar

Power supply 400V, 3ph, 32 Amp

Power output 23kW, 60A

Minimum weld size 500mm x 500mm

Maximum weld size 3000mm x 2580mm

Maximum profile height 160mm

Minimum profile height 50mm

Maximum profile width 120mm

Machine height 2000mm

Machine length 4300mm

Machine width 5200mm

Machine weight 3200kg

Gallery