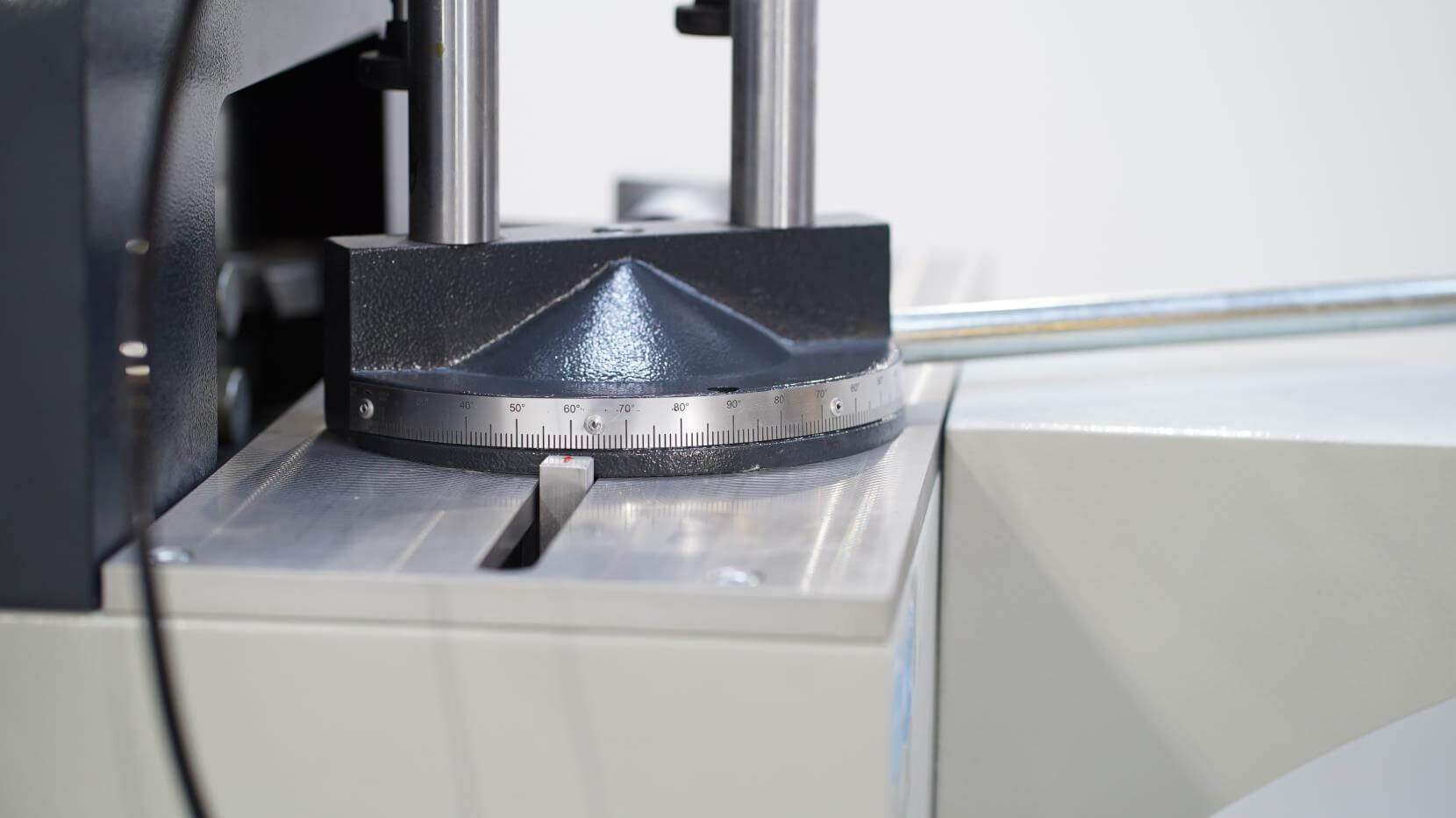

End Milling Machine

FA-154

FA-154 End Milling Machine automatically carries out the process of notching the aluminum end milling profiles in accordance with the profiles they will join. It enables notching at main and intermediate angles up to 45 ° on the left and 30 ° on the right. For each profile to be milled, a suitable cutting blade must be attached to the machine. Notching knives up to Ø160 mm diameter can be attached to the machine. Upon customer request, it can be manufactured as single phase 220V or three phase 380V during the production phase.

Overview

- For end milling of transom in aluminum profiles

- Automatic feed of the milling unit

- Able to route at varying angles up to 45° left and 30° right

- Vertical pneumatic profile clamping system enables optimum profile holding

- Cutter lubricating system for aluminum profiles

- Tool kit

- Operating and Maintenance manual

- Two-year limited warranty (see Notes)

Available Options

- Hydro-pneumatic feed system to route aluminum profiles

- Custom blades for machining profiles

Specs & Sizing

Operating voltage: 400 V, 3 ph., 50/60 Hz

Power output: 1.1 kW (3.11, 1.87, 1.56 or 1.30 F.L.A. (calculated))

Maximum cutter diameter: 160 mm (6.29 in.)

Spindle speed: 2,800 rpm (50 Hz), 3,360 rpm (60 Hz)

Maximum routing height: 90 mm (3.54 in.)

Maximum routing depth: 30 mm (1.18 in.)

Maximum profile width: 120 mm (4.72 in.)

Maximum profile height: 90 mm (3.54 in.)

Working air pressure: 6-8 bar (90-120 psi)

Air consumption: 70 l/min. (2.47 cfm)

Machine height: 1,220 mm (48.03 in.)

Machine length: 960 mm (37.79 in.)

Machine width: 820 mm (32.28 in.)

Machine weight: 75 kg (165 lbs.)

Gallery