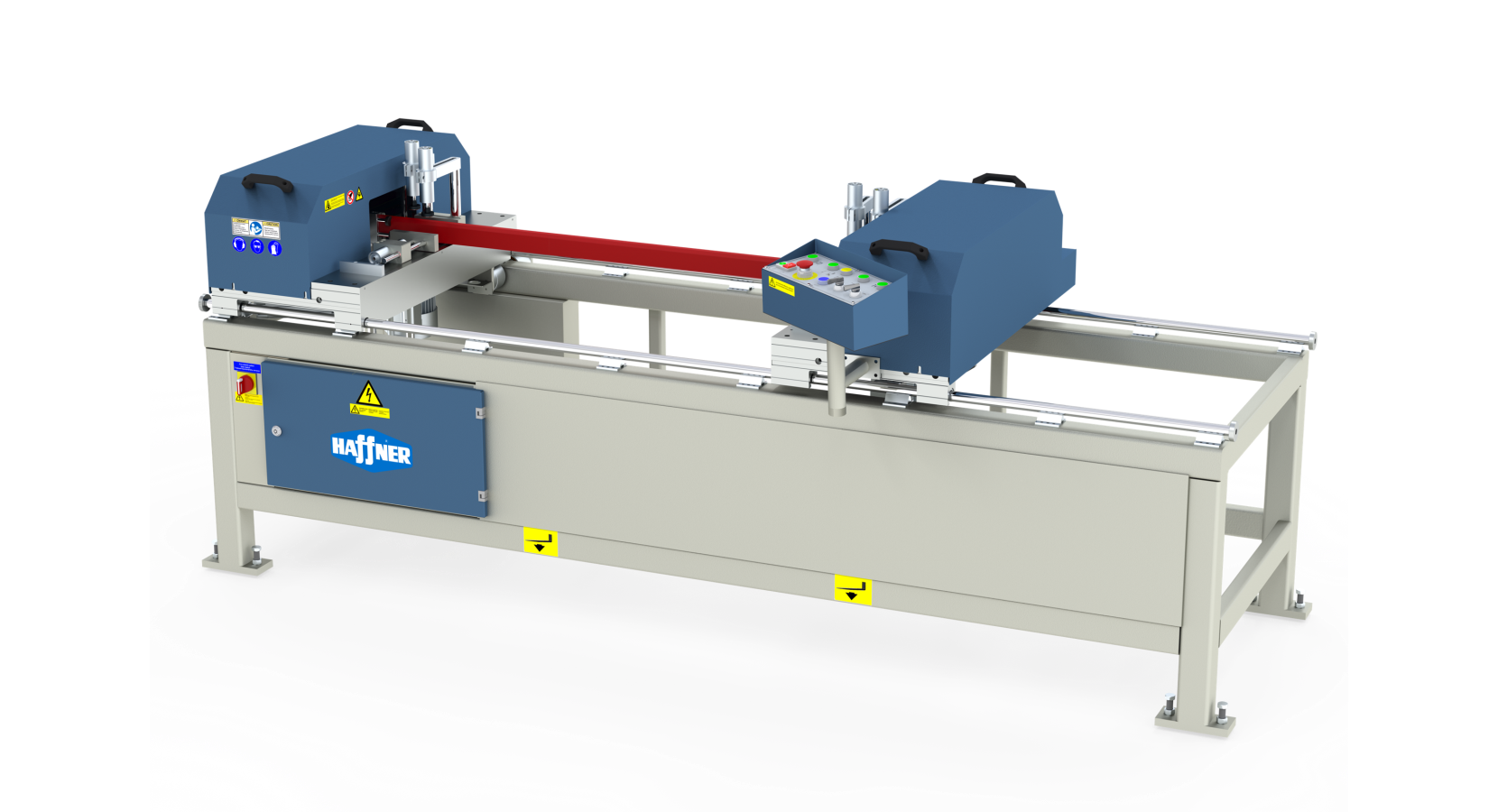

Double Head End Milling Machine

FA-526

FA-526 is designed for milling of two ends of transom profiles with a single operation. The movable head is manually positioned according to the profile length and manually clamped. Automatically releases the fixed head after milling and repositioning at the same length for second transom. Milling unit is fed automatically. Two different series of transom profiles can be processed without changing the cutter set. Tools are positioned with a pneumatic feed cylinder. Vertical and horizontal pneumatic profile clamping system enables optimum profile fixation.

Overview

- Milling of two ends of transom profiles with a single operation

- Automatic feed of the milling unit

- The movable head is manually positioned according to the profile length and manually clamped

- Automatic release of the fixed head after milling and repositioning at the same length for second transom

- Vertical and horizontal pneumatic profile clamping system enables optimum profile holding

- Tools are positioned with a pneumatic feed cylinder

- Two different series of transom profiles can be processed without changing the cutter set

Video Demo & Application

Specs & Sizing

Operating voltage: 400V, 3 ph., 50/60 Hz

Connected load: 2.2 kW (6.22, 3.74, 3.11 or 2.60 F.L.A. (calculated))

Maximum cutter diameter: 160 mm (6.29 in.)

Spindle speed: 2,800 rpm (50 Hz), 3,360 rpm (60 Hz)

Maximum routing height: 90 mm (3.54 in.)

Maximum routing depth: 30 mm (1.18 in.)

Maximum profile width: 120 mm (4.72 in.)

Maximum profile height: 90 mm (3.54 in.)

Working air pressure: 6-8 bar (90-120 psi)

Air consumption: 70 l/min. (2.47 cfm)

Machine height: 1,150 mm (45.27 in.)

Machine length: 3,150 mm (124.01 in.)

Machine width: 1,200 mm (47.24 in.)

Machine weight: 350 kg (775 lbs.)

Gallery