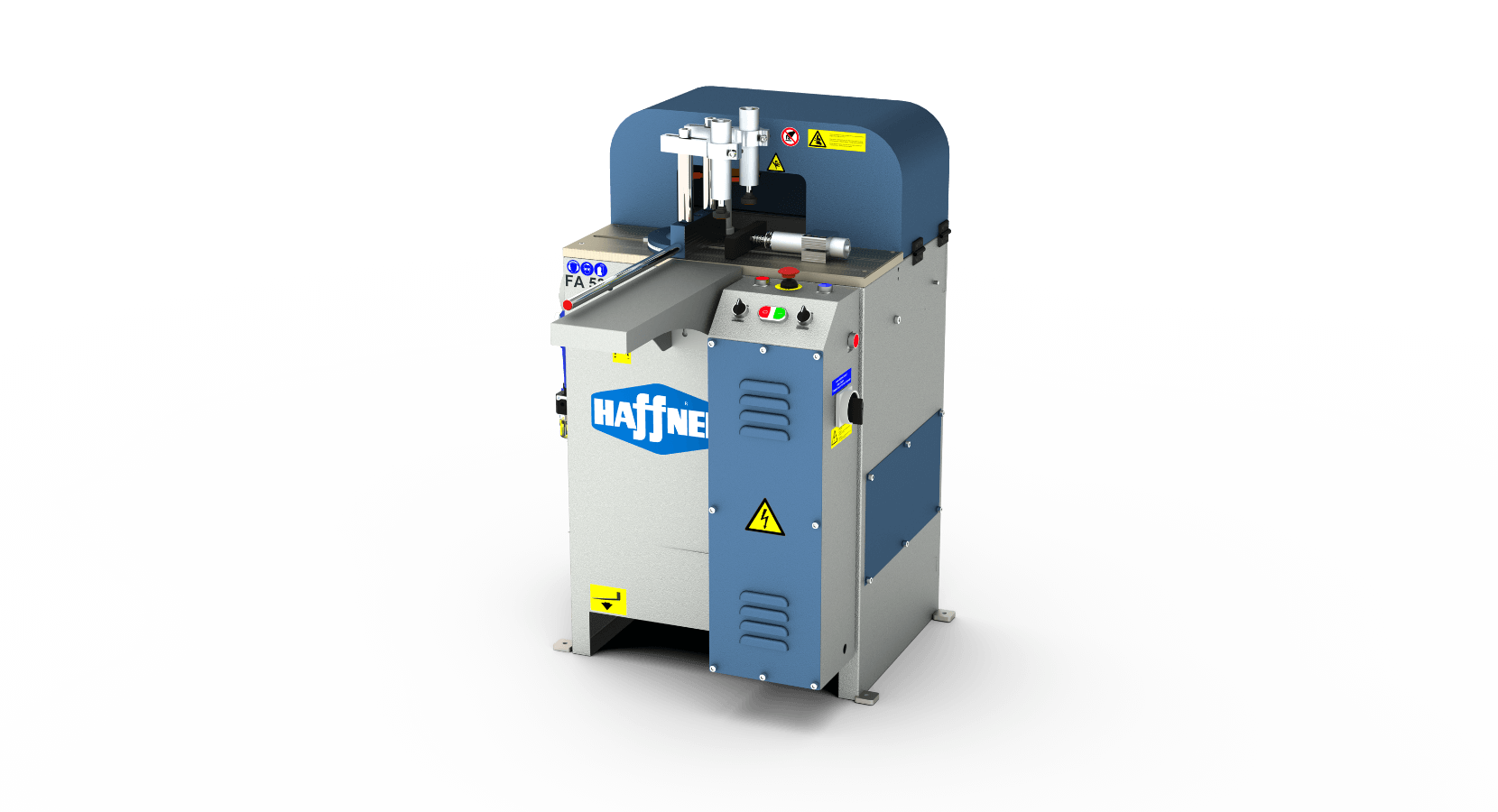

End Milling Machine

FA-533

FA-533 End Milling Machine automatically performs the process of notching aluminum mid-record profiles in accordance with the profiles they will join. It enables notching at main and intermediate angles up to 45 ° on the left and 30 ° on the right. For each profile to be milled, a suitable cutting blade must be attached to the machine. Two different notching knives can be attached to the machine to perform notching of different profiles.

Overview

- For end milling of transom in PVC and aluminum profiles

- Two different series of transom profiles can be processed without changing the cutter set

- Vertical and horizontal pneumatic profile clamping system enables optimum work piece holding

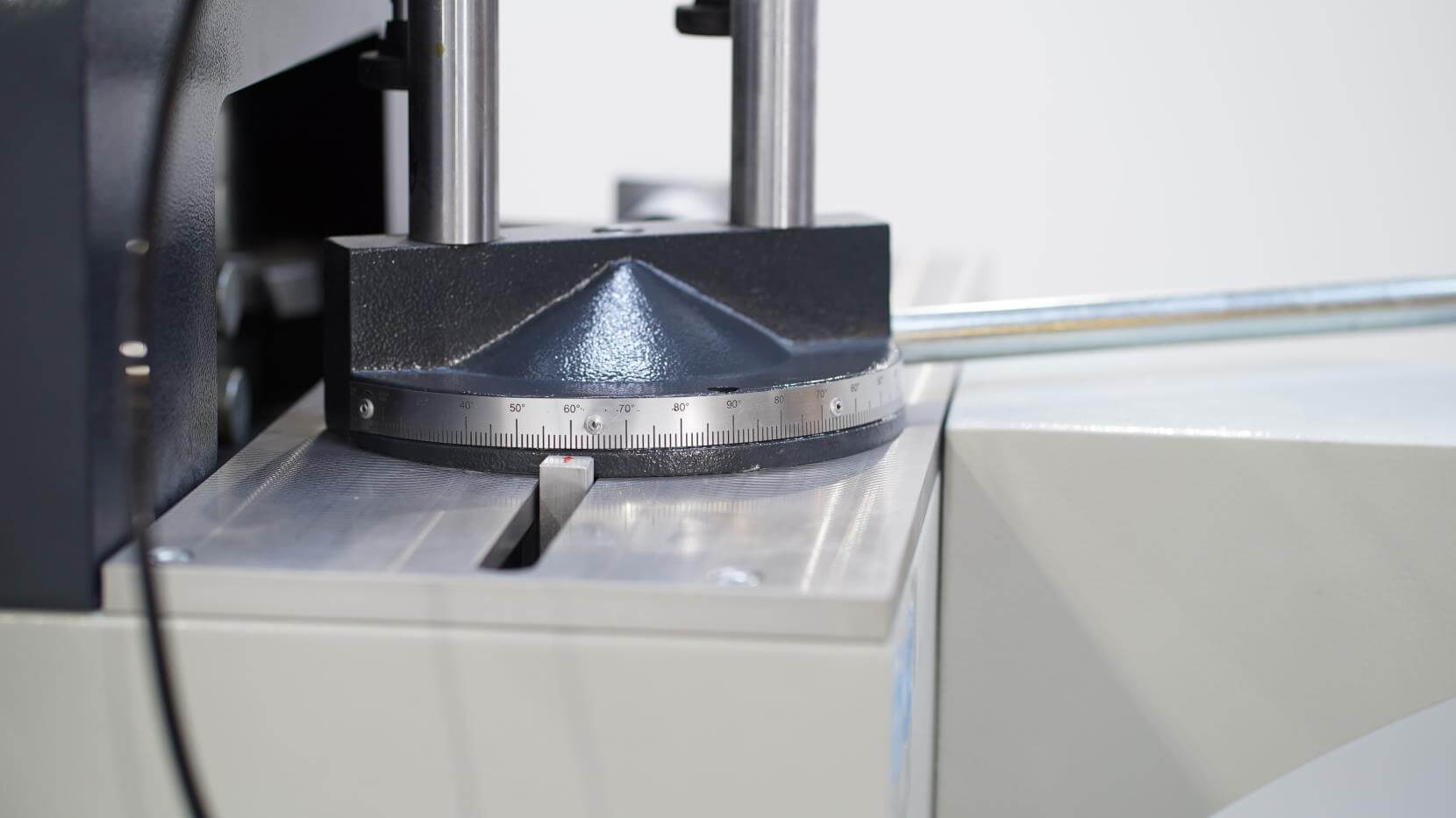

- Able to route at varying angles up to 45° left and 30° right

- Tools are positioned by a pneumatic feed cylinder

- Automatic milling unit feed

- The saw blade feed speed can be adjusted

- Cutter lubricating system for PVC and aluminum profiles

- Hydro-pneumatic feed system to route PVC and aluminum profiles

- Tool kit

- Operating and Maintenance Manual

Available Options

- Custom blades for machining profiles

Specs & Sizing

Operating voltage: 400 V, 3 ph., 50/60 Hz

Connected load: 1.1 kW (3.11, 1.87, 1.56 or 1.30 F.L.A. (calculated))

Maximum cutter diameter: 160 mm (6.29 in.)

Spindle speed: 2,800 rpm (50 Hz), 3,360 rpm (60 Hz)

Maximum routing height: 90 mm (3.54 in.)

Maximum routing depth: 30 mm (1.18 in.)

Maximum profile width: 120 mm (4.72 in.)

Maximum profile height: 90 mm (3.54 in.)

Working air pressure: 6-8 bar (90-120 psi)

Air consumption: 70 l/min. (2.47 cfm)

Machine height: 1,220 mm (48.03 in.)

Machine length: 960 mm (37.79 in.)

Machine width: 820 mm (32.28 in.)

Machine weight: 95 kg (200 lbs.)

Gallery