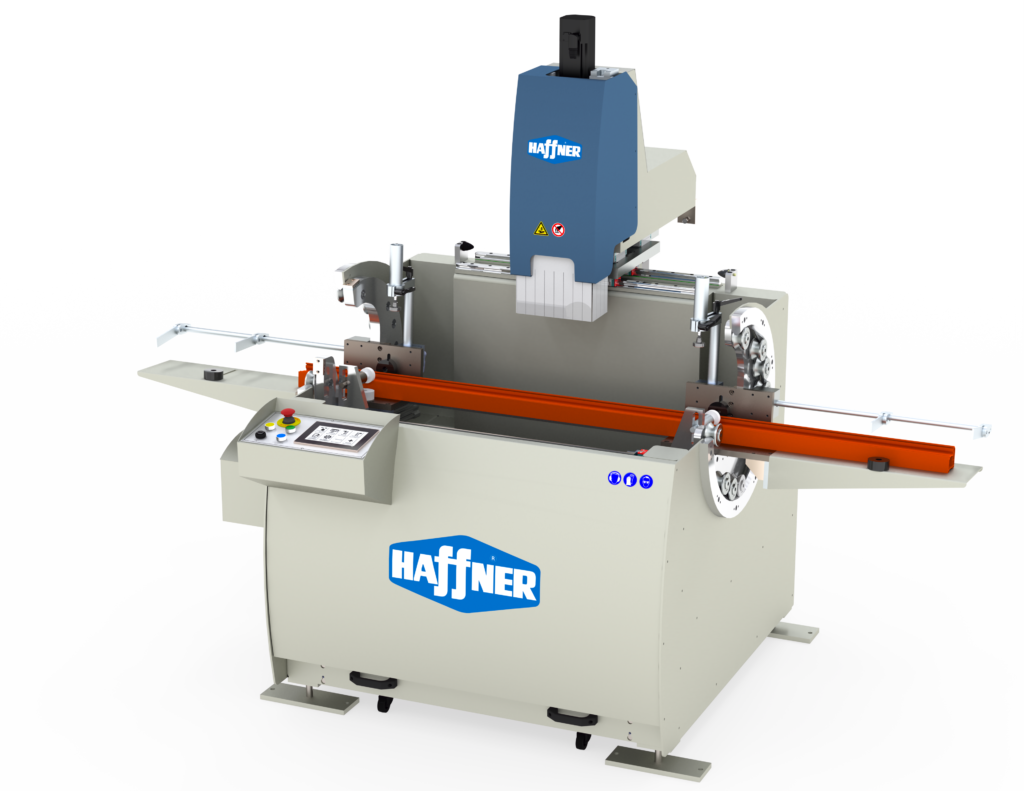

MAC-140/50 Aluminum/PVC Profile Processing Center

MAC-140/50

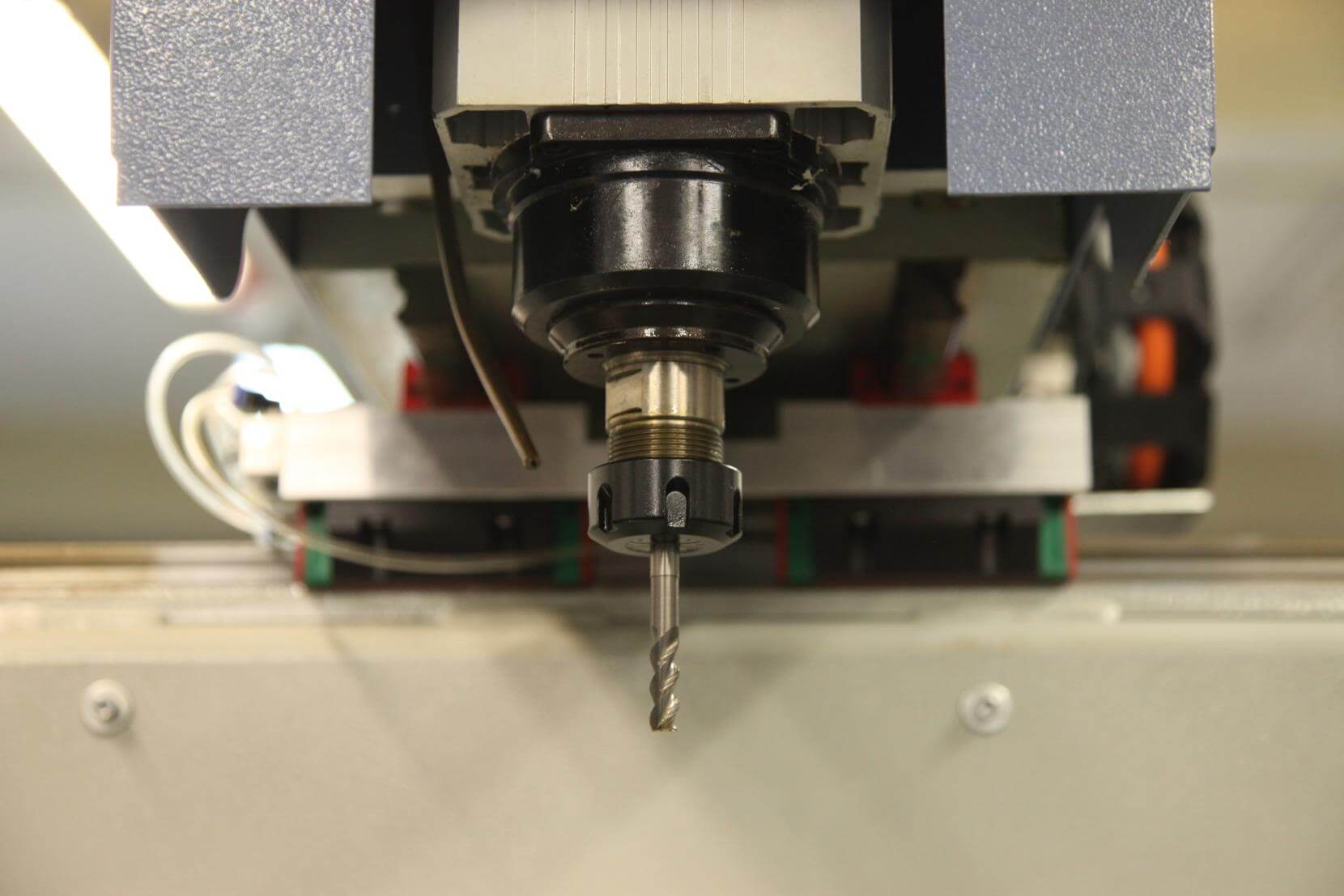

MAC-140/50 Profile Machining Center is designed to perform the milling, drilling and marking operations on the profiles in a computer-controlled and compact manner. The operations performed on more than one cutting machine are collected in a single machine, ensuring production speed and quality standardization, while labor resources are optimized.

Overview

- Able to move in 3 axes simultaneously on the work piece (Axis interpolation)

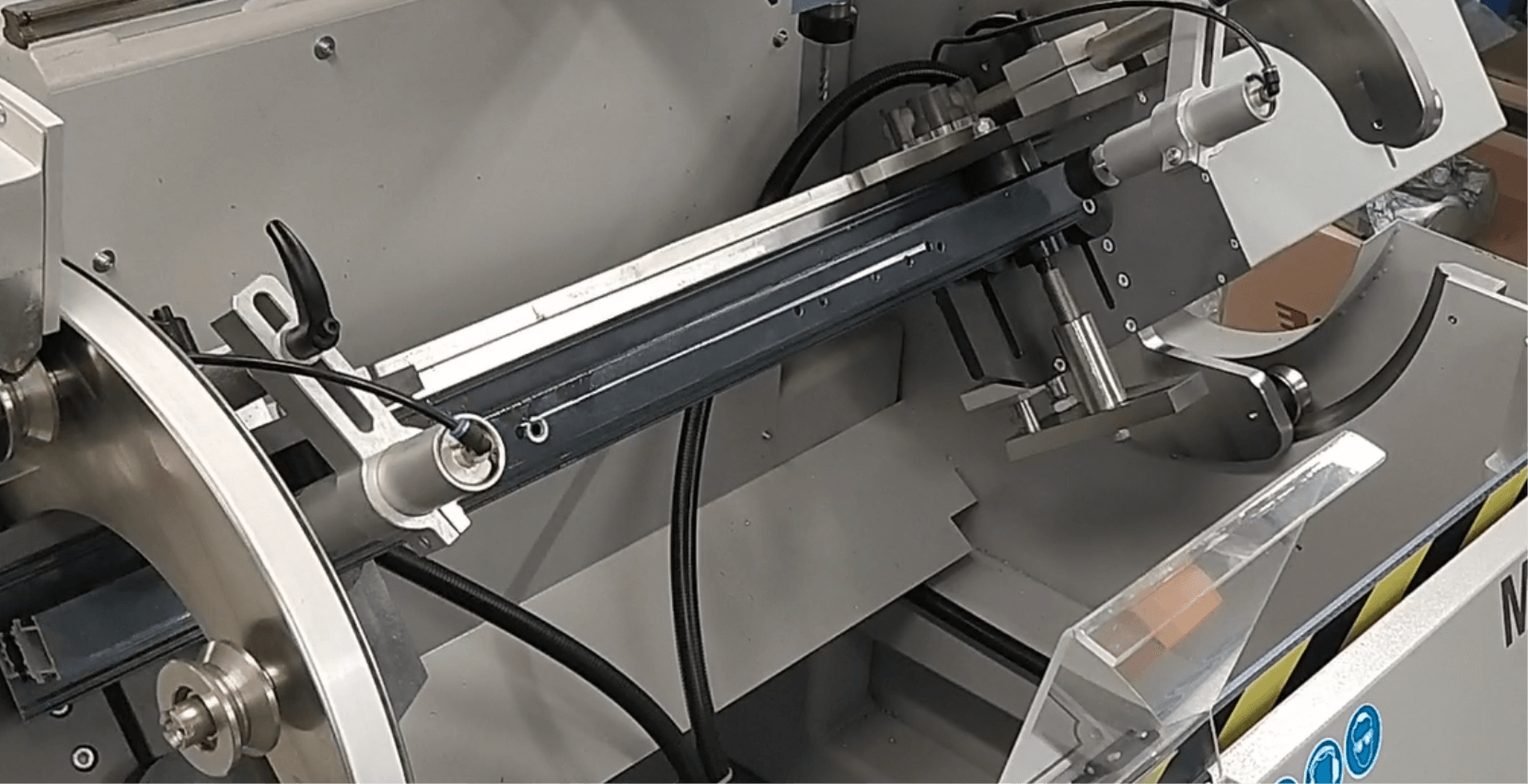

- Servo axis rotating table

- Machines angles for all surfaces of the profile with the 4th axis

- Works with high accuracy on aluminum door, window and facade profiles (± 0.1mm (± 0.004 in.))

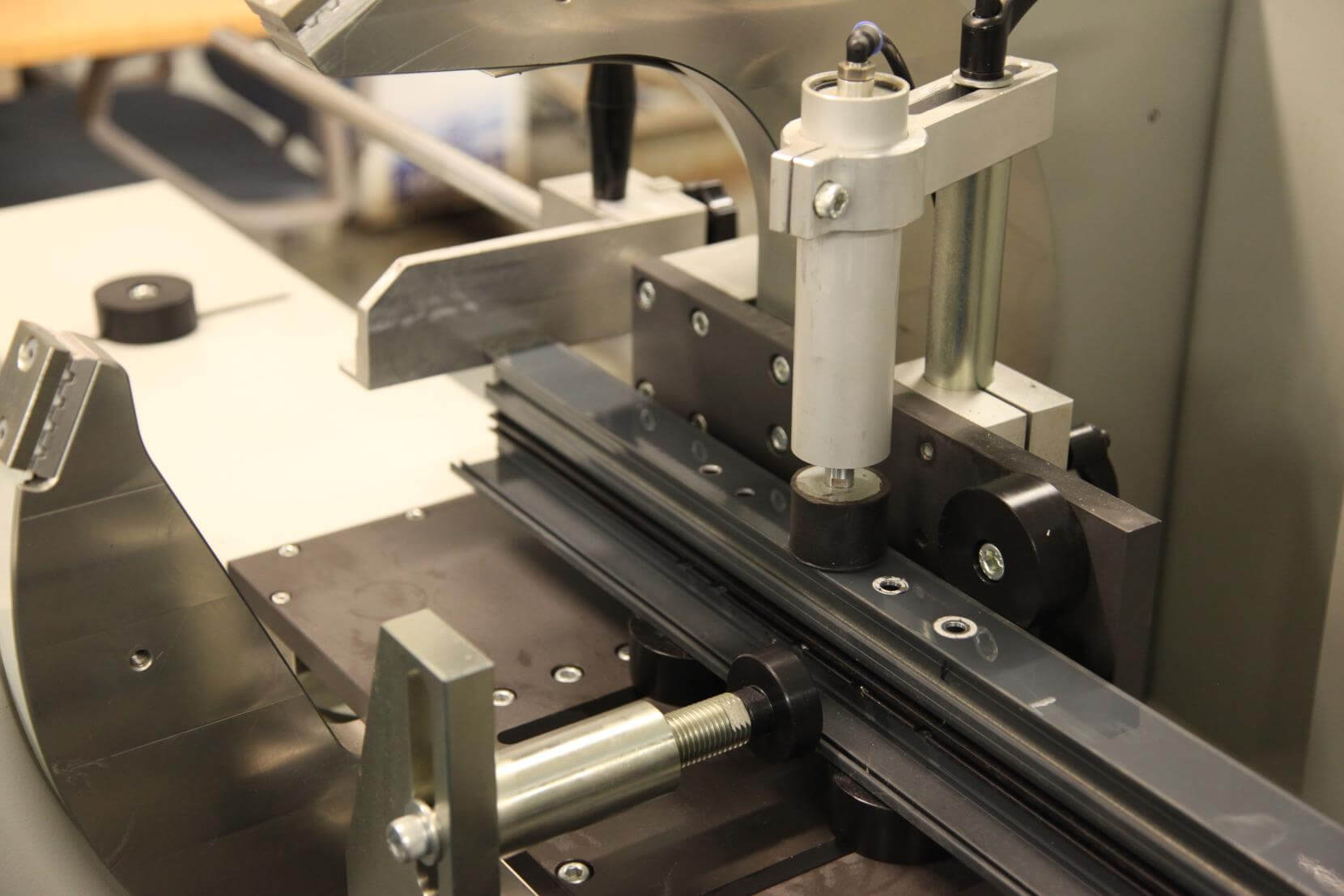

- Holds the profiles rigidly with two clamps

- Central lubrication system to ease machine maintenance

- Tool kit

Video Demo & Application

Specs & Sizing

Operating voltage: 400, 3 ph., 60 Hz

Connected load: 9 kW (25.47, 15.28, 12.74, or 10.63 F.L.A. (calculated))

Spindle motor: 5.5 kW (7.37 hp.), 18,000 rpm

Air consumption: 80 l/min. (2.82 cfm)

Minimum profile height: 30 mm (1.18 in.)

Maximum profile height: 200 mm (7.87 in.)

Maximum profile width: 200 mm (7.87 in.)

Machine height: 1,965 mm (77.36 in.)

Machine length: 2,595 mm (102.16 in.)

Machine width: 1,745 mm (68.70 in.)

Machine weight: 850 kg (1,875 lbs.

Gallery