MAC-340 Aluminum Profile Processing Center

MAC-340

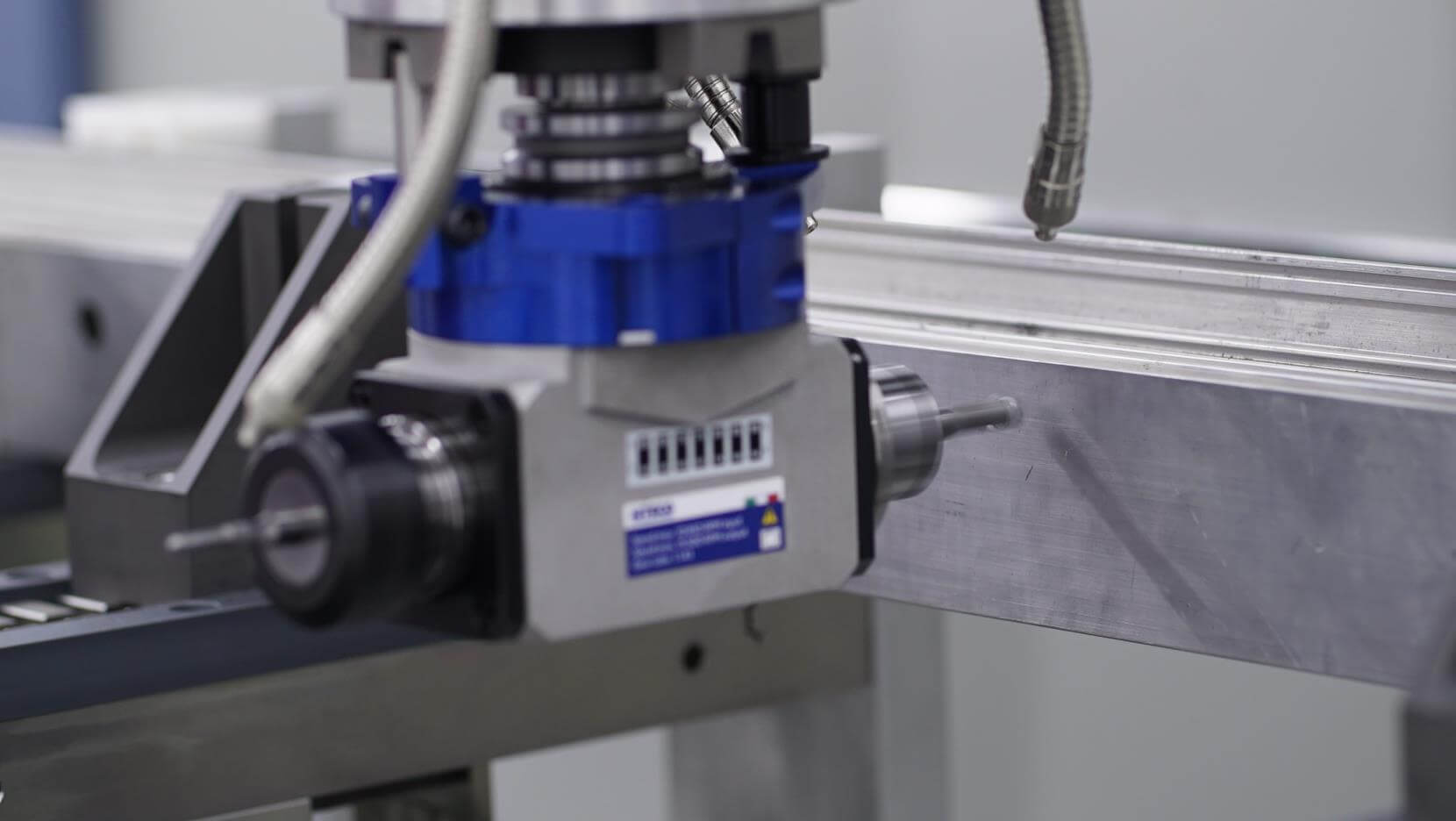

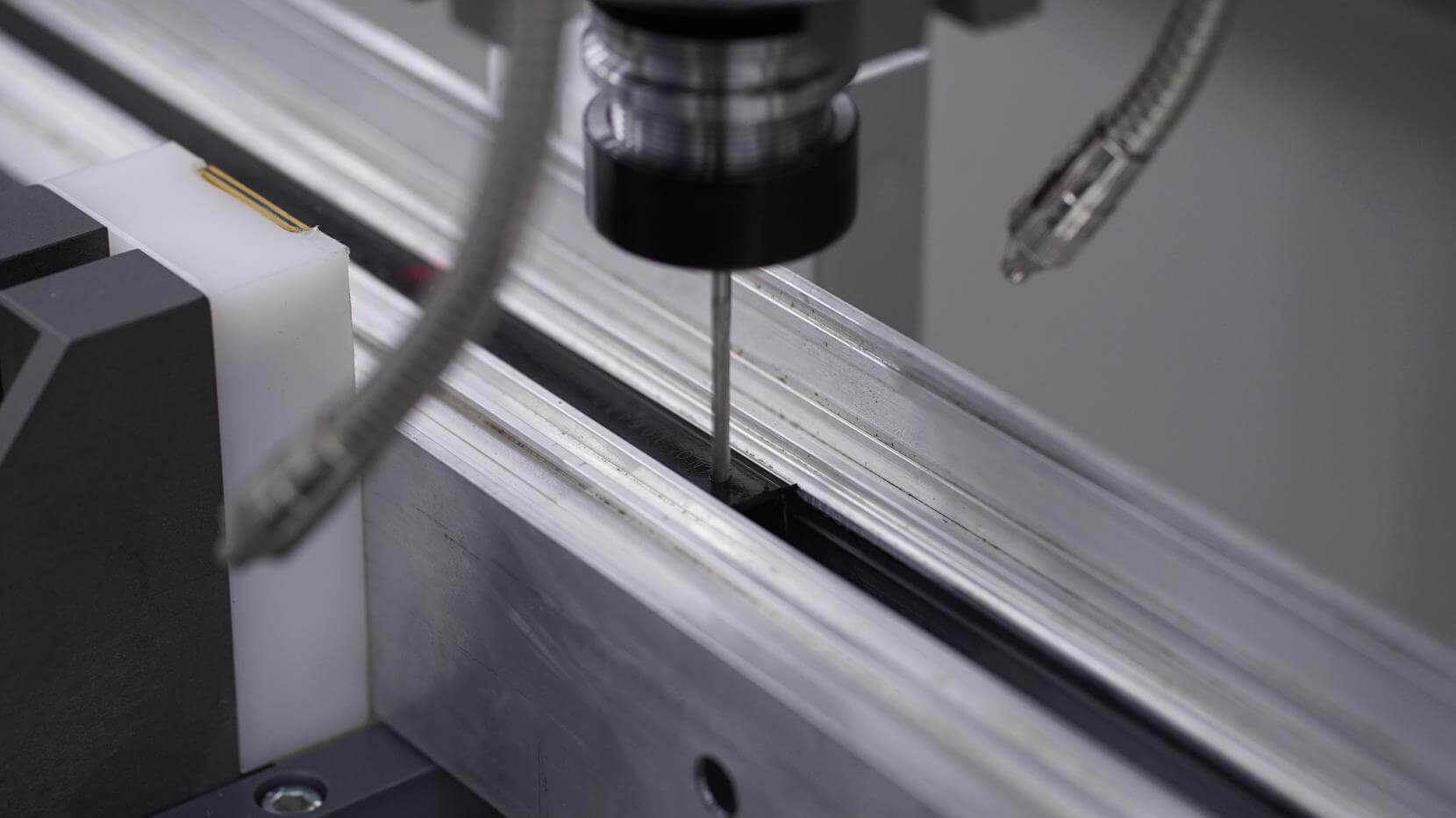

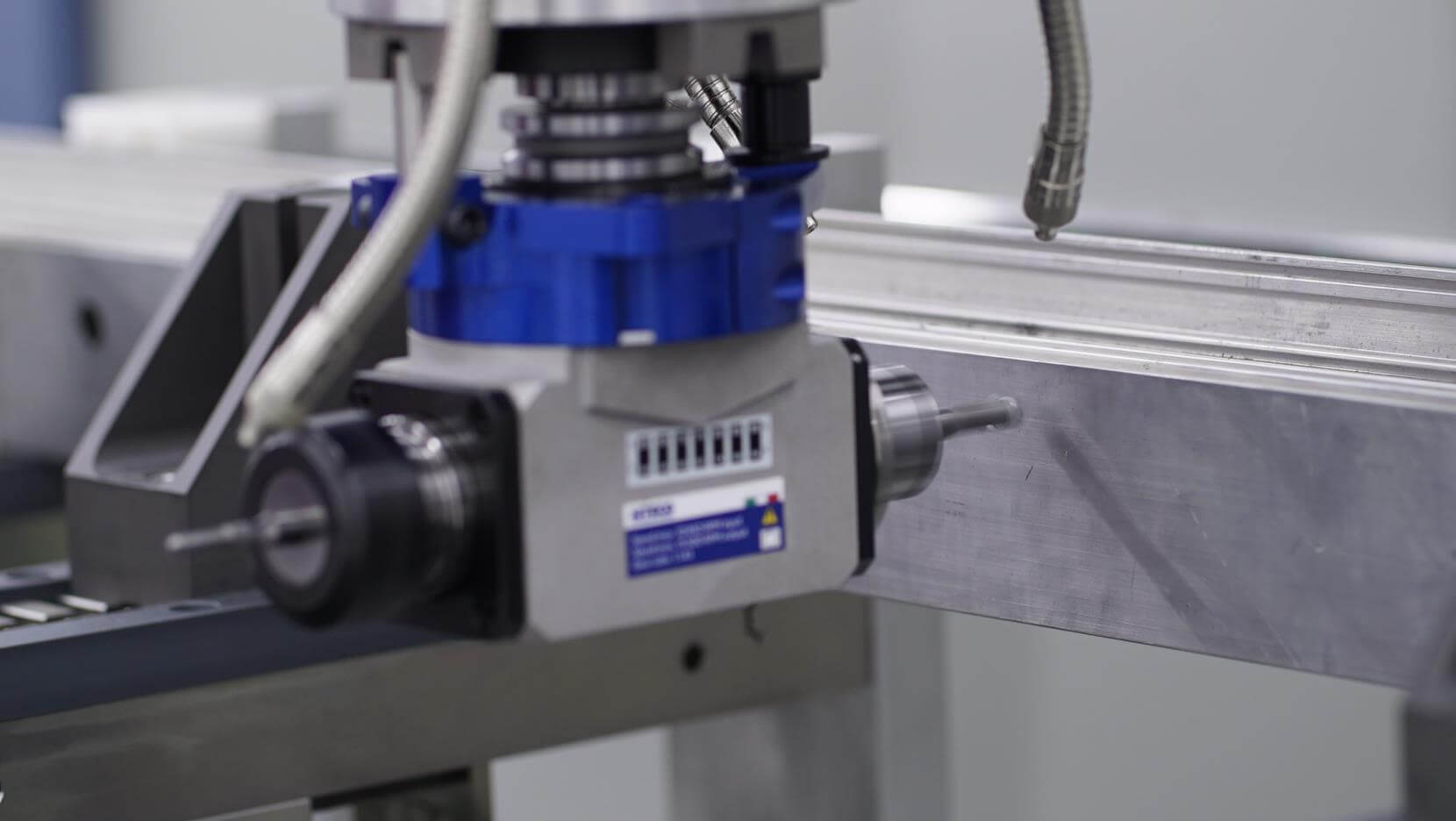

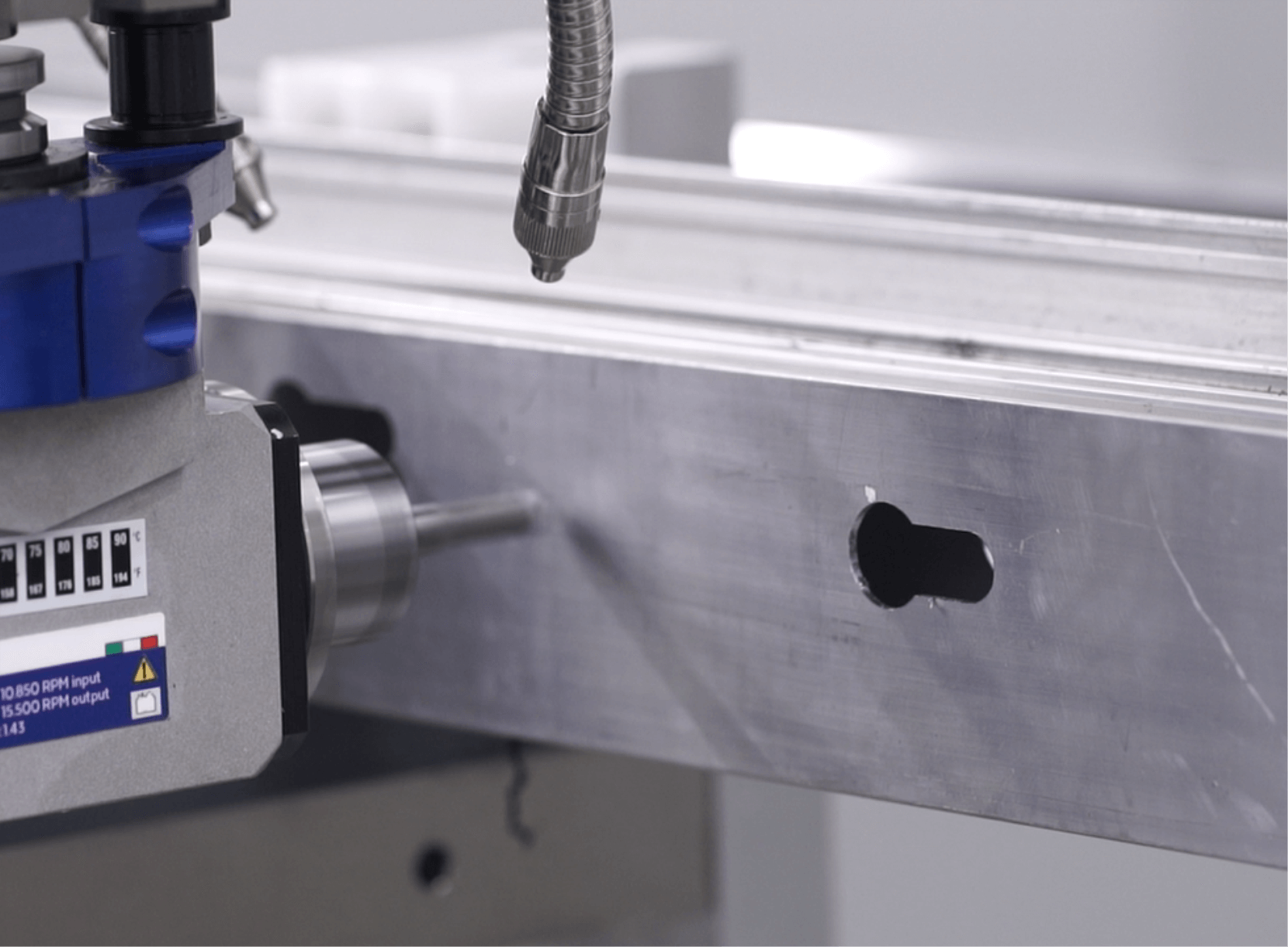

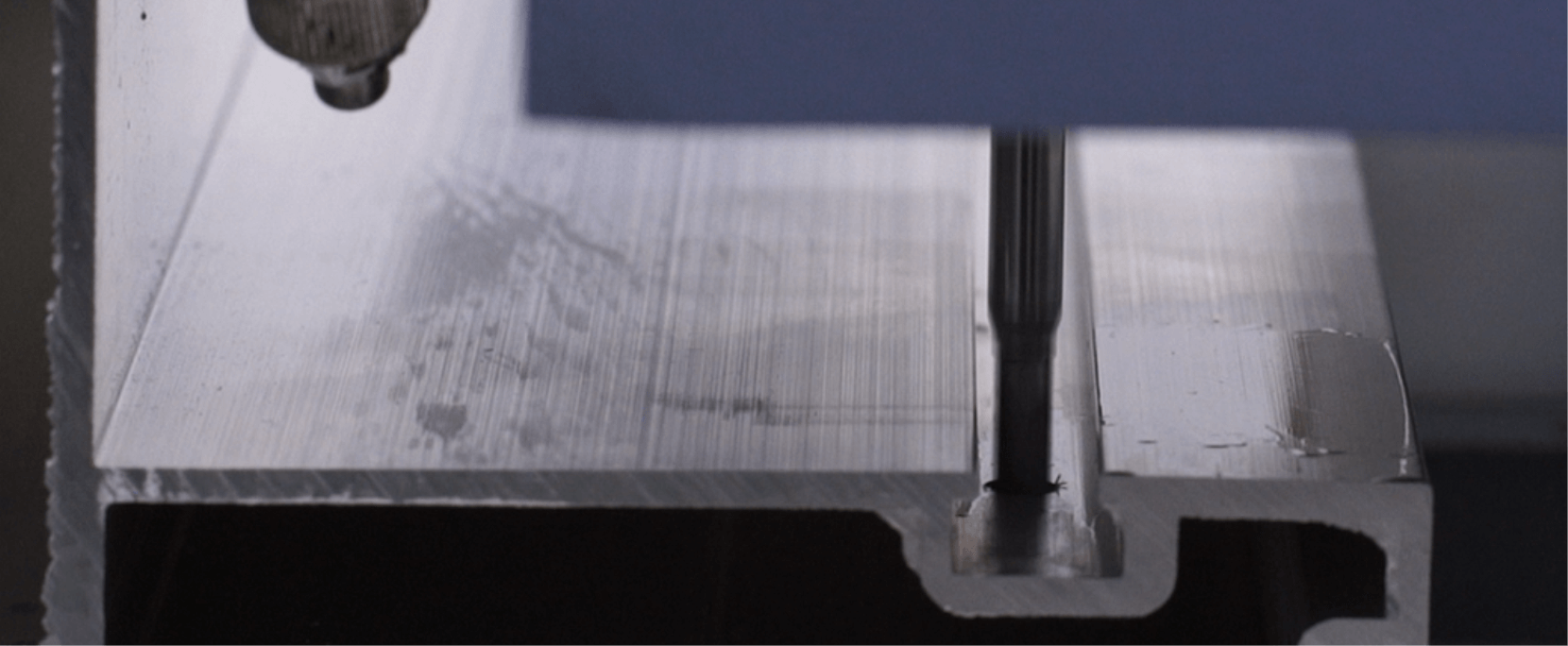

MAC-340 Profile Machining Center is designed to perform the standard operations on profiles such as milling, drilling, milling and marking, as well as flowdrill and tapping, with computer control. The operations previously performed on more than one cutting machine are collected in a single machine, ensuring production speed and quality standardization, while labor resources are optimized. With the ability to interpolate on the profile to be processed in 3 axes, it performs all operations on the profile with 0.1 mm precision, processing profiles of different designs and sizes. With a 7.5 kW water-cooled spindle, it provides the opportunity to process profiles up to 4000mm in 3 axes. The system includes 7 tools with double-sided angle processing head and tool change is automatic, according to the process to be performed.

Overview

- PC controlled 3-axis interpolated CNC machine

- Moves in 3 axes simultaneously on the work piece (axis interpolated)

- Works with high accuracy on aluminum door, window and facade profiles (± 0.1 mm (± 0.004 in.))

- Works on 3 mm (0.12 in.) thick iron profiles

- Automatic tool changing using a magazine which holds 7 tools including an angle head

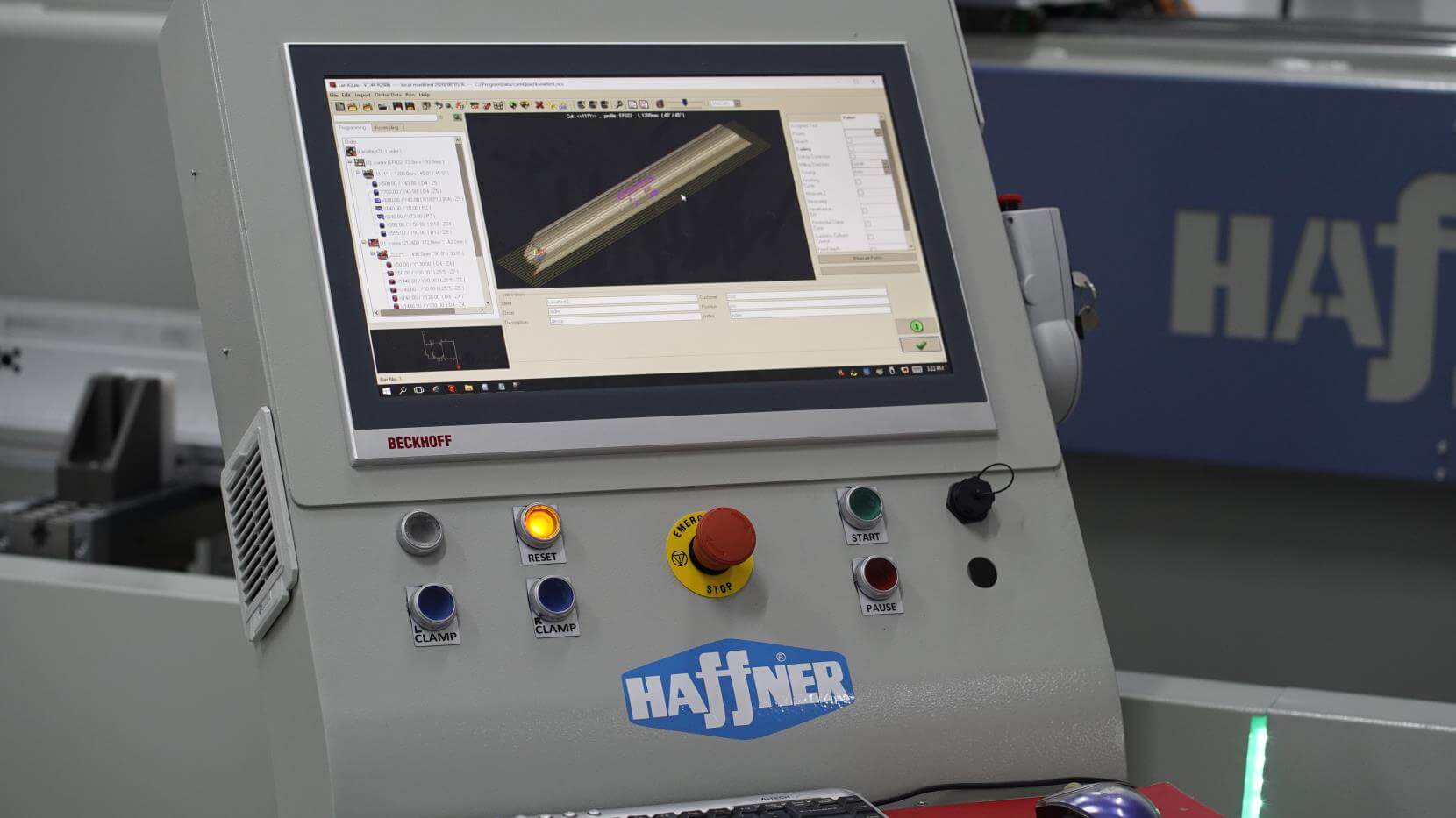

- 19” touch screen monitor

- Industrial PC works between 0°C – 55°C (32°F – 131°F) without an additional fan

- Easy to perform operations on the profile with the CAD – CAM program

- Full integration with various on facades and aluminum door/window production software

- 3D machine simulation which enables displaying the process in 3D

- Thread cutting, flow drill and countersink operations

- Central lubrication system to ease machine maintenance

Available Options

- Double station operation option allows for a 30% capacity increase by loading and unloading at another station while working at one station

- Automatic clamp positioning (clamp moves according to position of processing point during operation)

- Up to six additional clamps can be added on request (AC-020)

- Fully enclosed cabin

- Angle routing head allows you to work the front, back, right and left surfaces. The tool is rotated accurately by means of an encoder on the electro spindle to the desired surface

- 2200 mm (7.87 in.) diameter disk mill and holder

- Barcode Reader (AK 002)

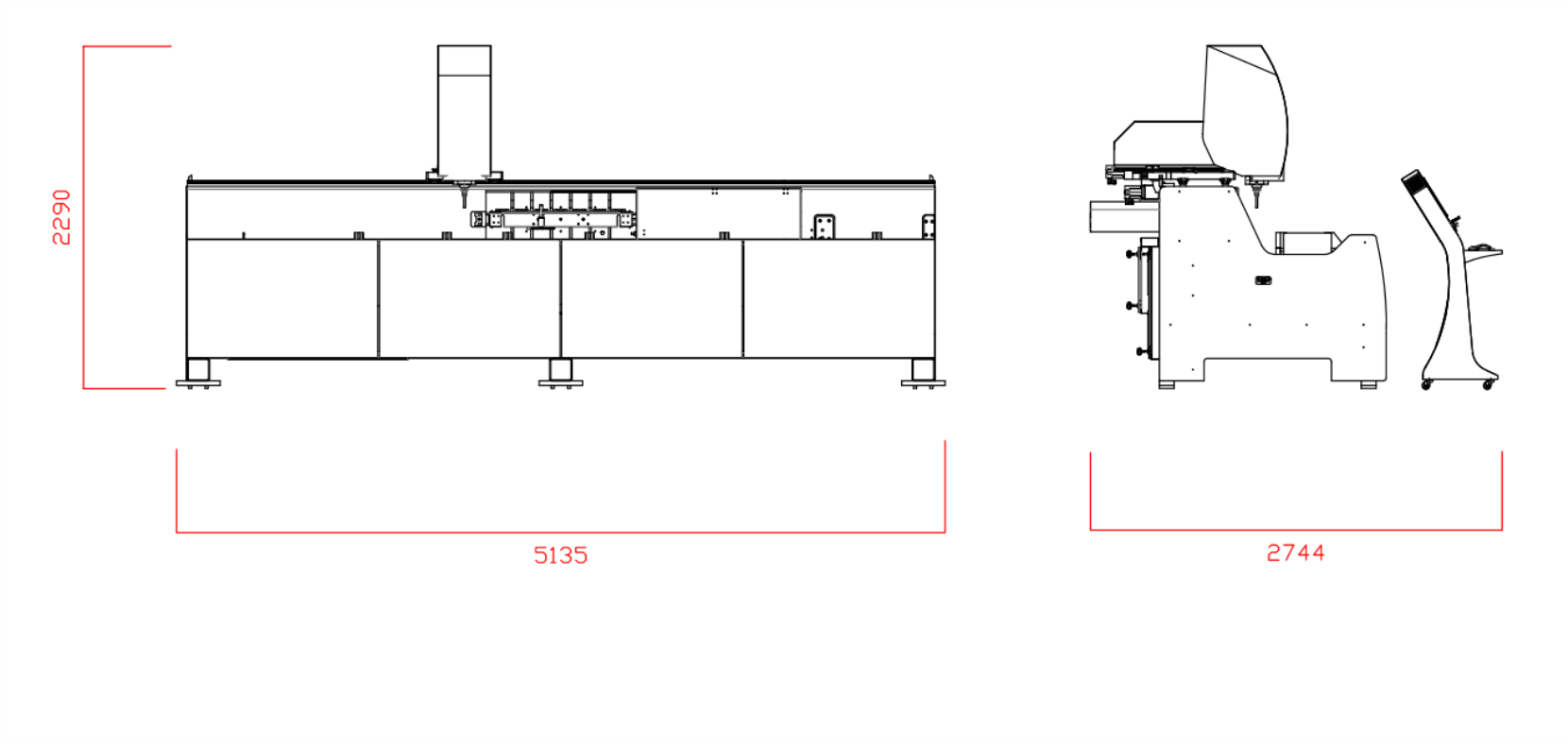

Specs & Sizing

X-axis: 4,000 mm (157.48 in.)

Y-axis: 250 mm (9.84 in.)

Z-axis: 220 mm (8.66 in.) Angled Head processing length:

X-axis: 4,000 mm (157.48 in.)

Y-axis: 175 mm (6.88 in.)

Z-axis: 220 mm (8.66 in.)

X-axis: 180 m/min (590.55 ft./min.)

Y-axis: 50 m/min (164.04 ft./min.)

Z-axis: 50 m/min (164.04 ft./min.)

Clamp Axis: 30 m/min (98.42 ft./min.) Position accuracy: ± 0.1 mm (± 0.004 in.)

Gallery