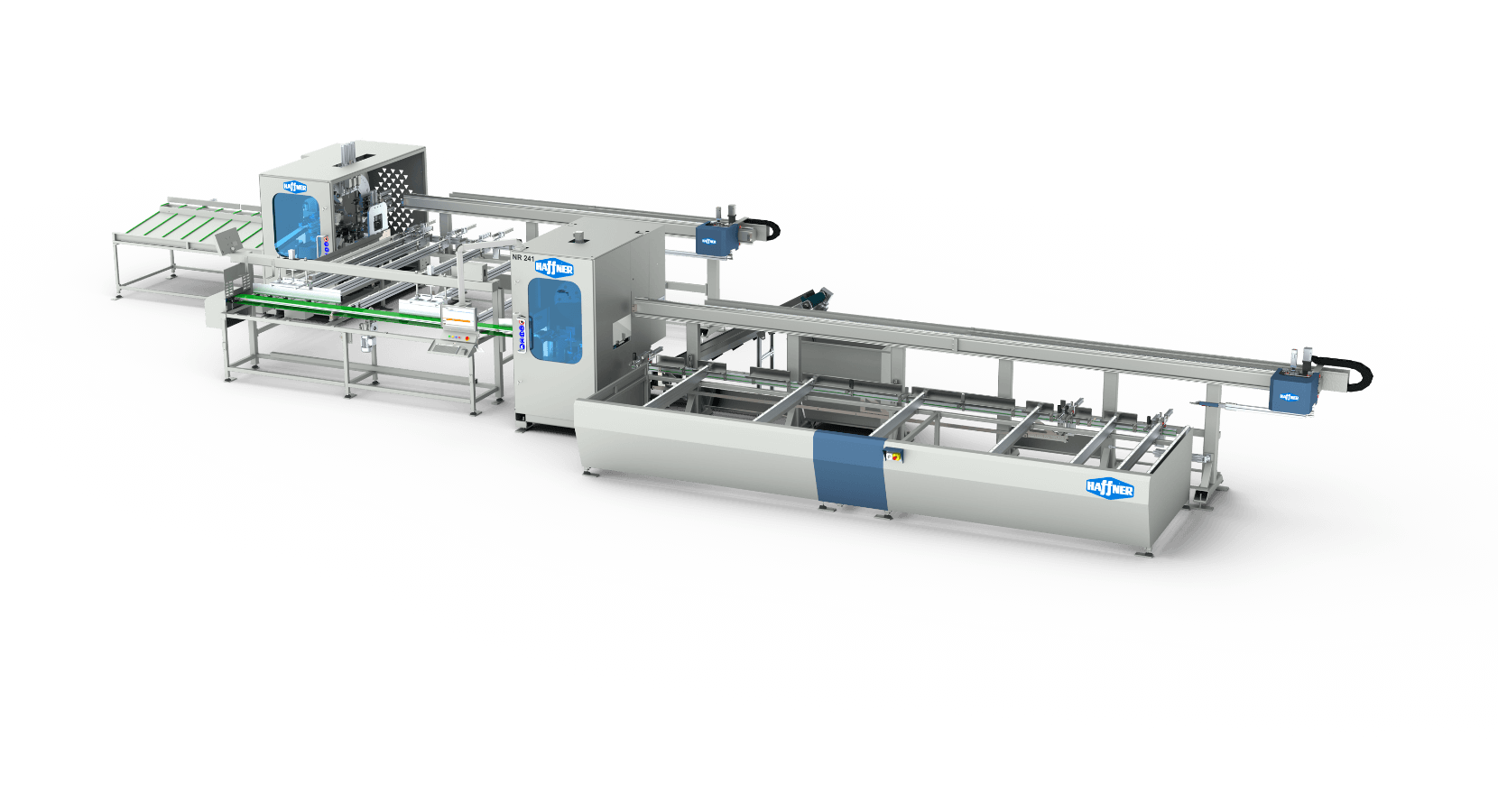

NR-241 PVC Profile Processing Center

NR-241

NR-241 Profile Machining Center; Milling and cutting stations are designed to work independently and simultaneously, to perform all milling, drilling, reinforcement steel screwing, routing and marking operations on PVC profiles in a single, computer controlled machine. The machining performance of 5 different machines can be obtained from a single machine, ensuring production speed and quality standardization while minimizing labor resources.

Overview

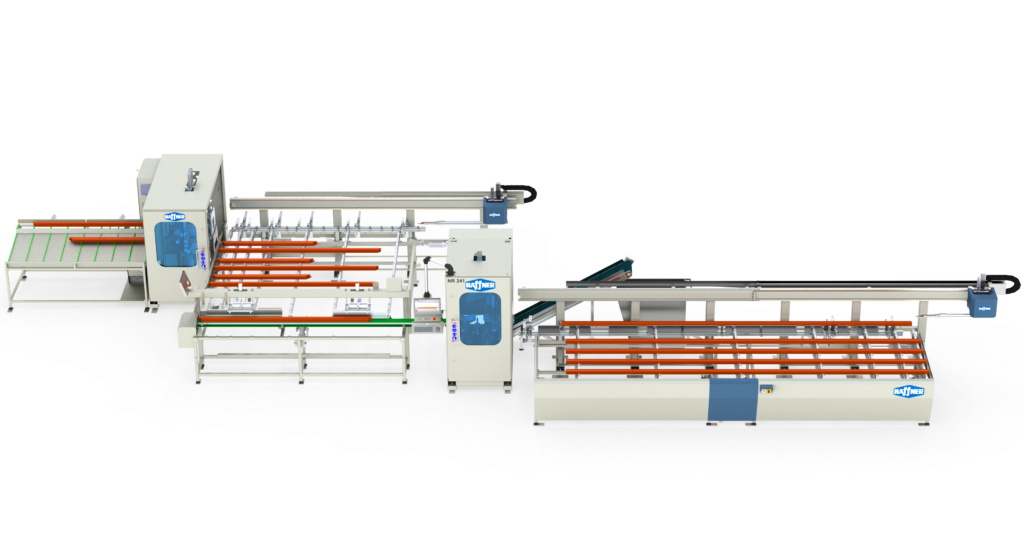

- Stacking of 10 profiles (max. 6,5 m length)

- Manual barcode labeling system integrated with single-lines

- Servo controlled automatic swing of the saw to all angles between 30° and 150° with 0.1° accuracy

- Drain slot routing, drilling and routing at variable angles

- Automatic screwing of reinforcement steels

- Drilling of fixation, triple handle and hinge holes together with the reinforcement steel

- Automatic conveyor belt system to transport scrap profiles to waste container

- Waste profiles longer than 500 mm. can be re-processed

- 19” touchscreen enables easy access and control

- High performance industrial PC works between 0°-55°C without fan

- All error messages can be monitored from the screen by a program developed by Haffner software engineering

- Online connection to the entire system enabling remote detection of malfunctions and maintenance

- Data transfer is available via network connection or USB interface

- Full integration with various window and door production software

Available Options

- End milling of transom profiles with two blade sets for two different profile cross sections

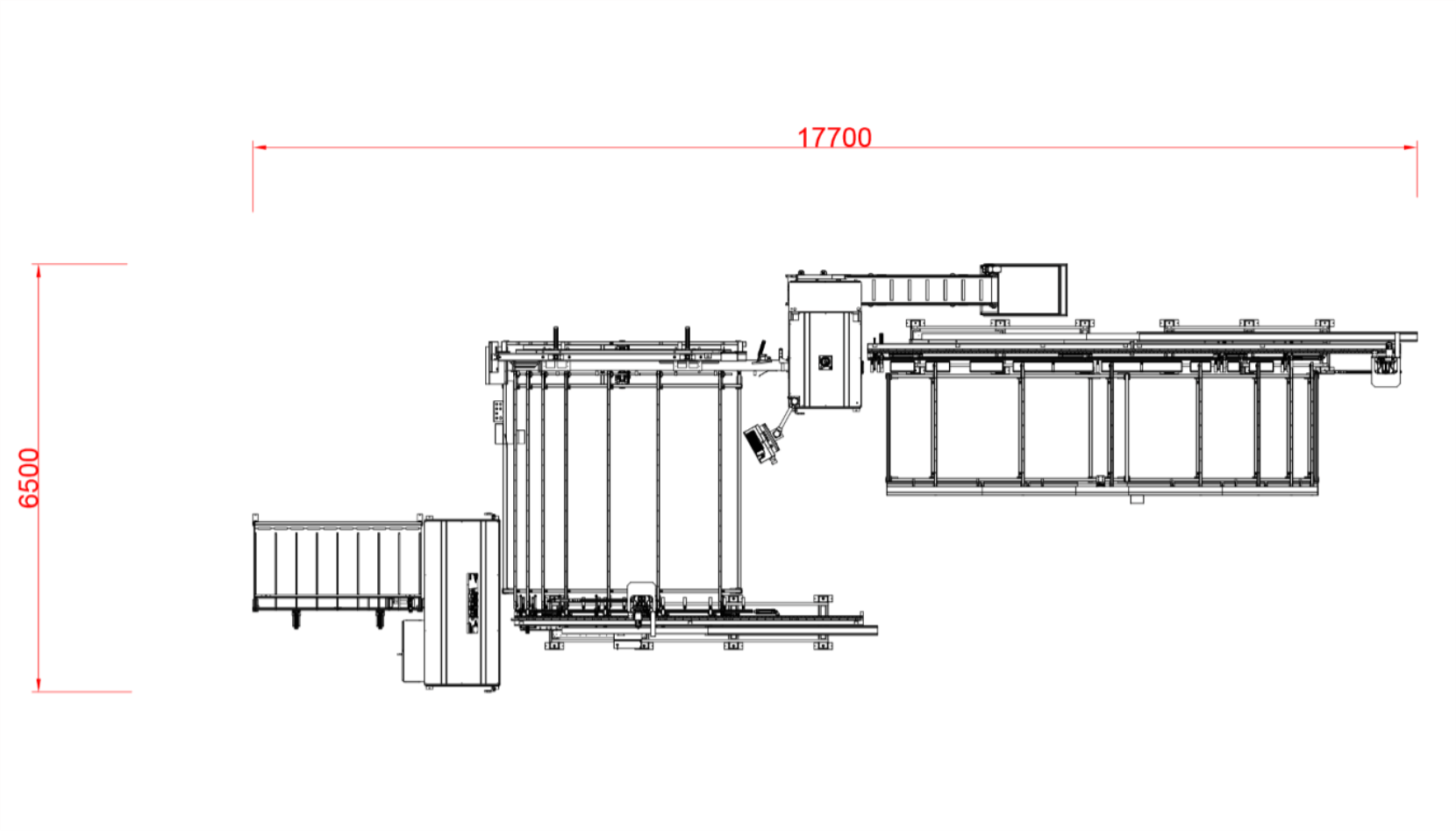

Specs & Sizing

Electrical rating: 400 V, 3ph, 50-60 Hz

Motor power: 18 kW, 45A

Saw diameter: 500 mm.

Max. profile height: 140 mm.

Min. profile height: 35 mm.

Max. profile width: 130 mm.

Min. profile width: 35 mm.

Max. length of raw profile: 6,500 mm.

Max. profile machining length: 3,500 mm.

Min. profile processing length: 330 mm.

Air pressure: 6-8 bar

Air consumption: 720 lt / min

Machine height: 2,350 mm.

Machine length: 18,000 mm.

Machine width: 6,500 mm.

Machine weight: 6,900 kg .

Gallery