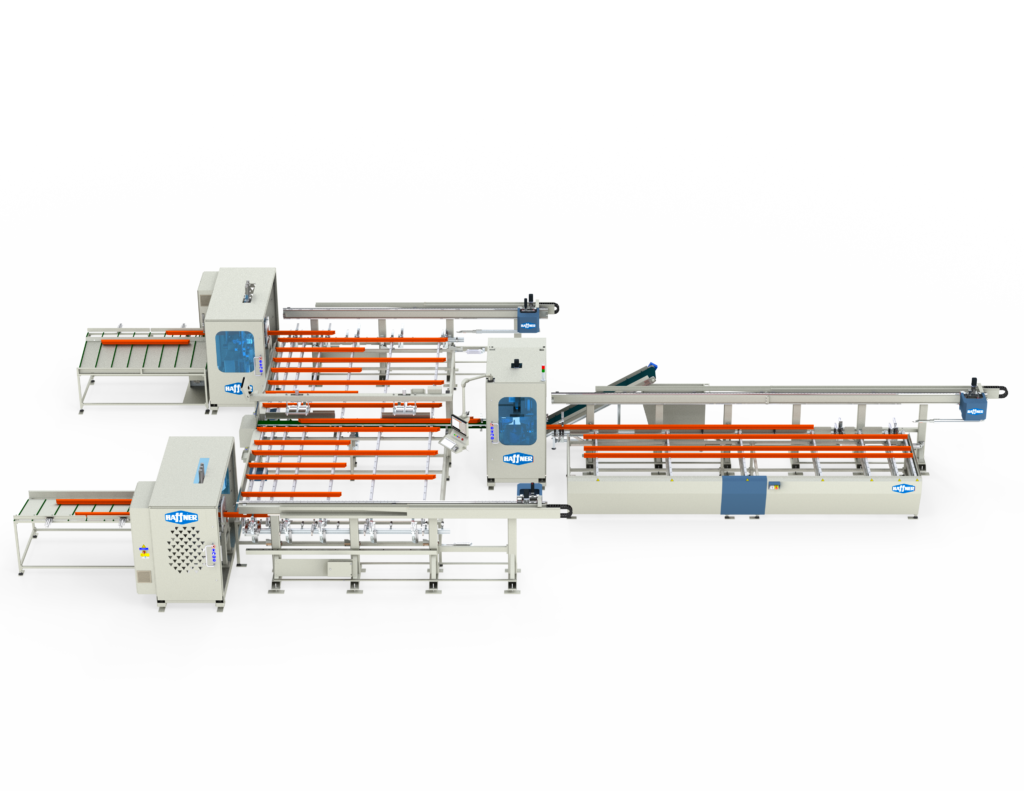

NR-242 PVC Profile Processing Center

NR-242

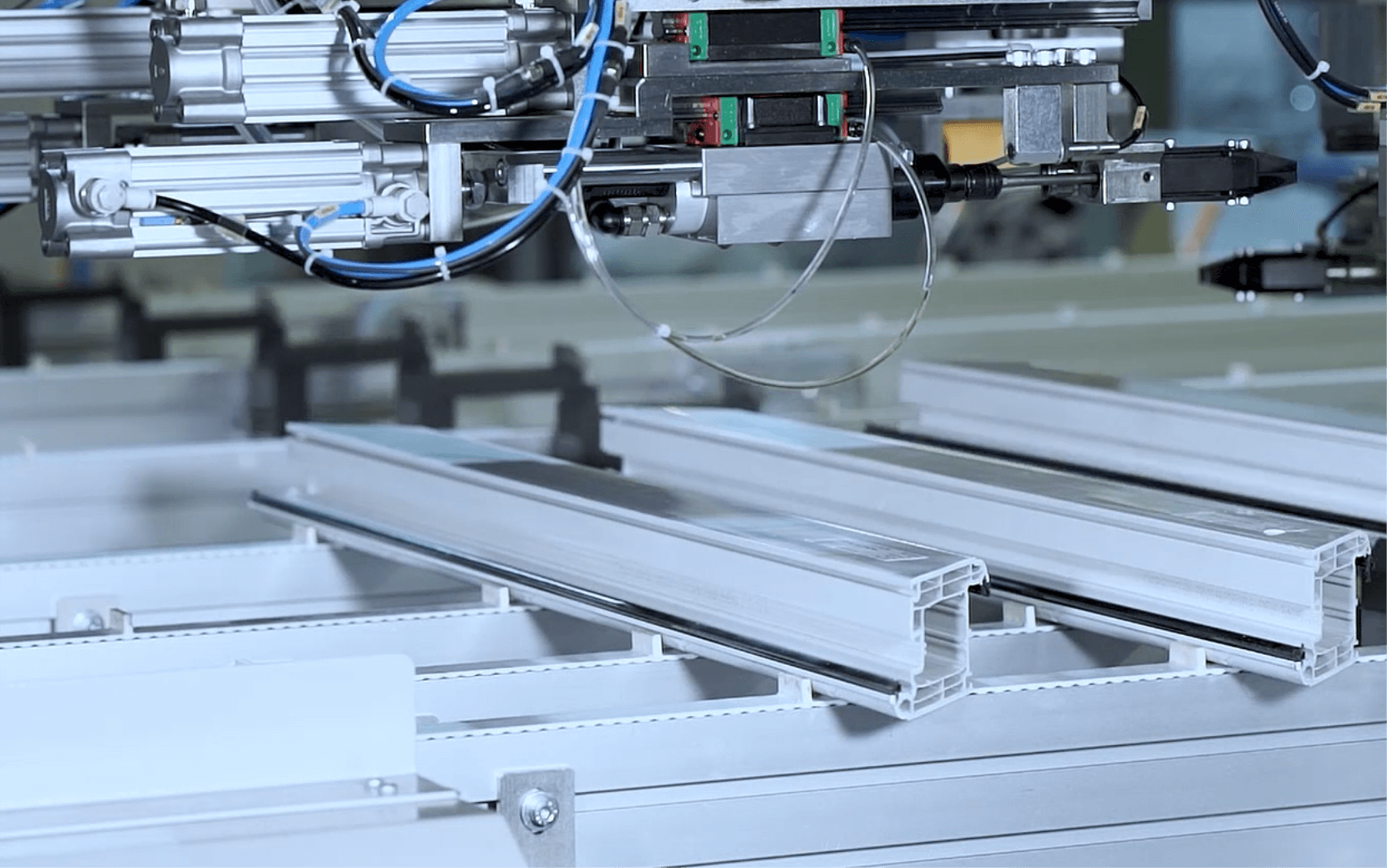

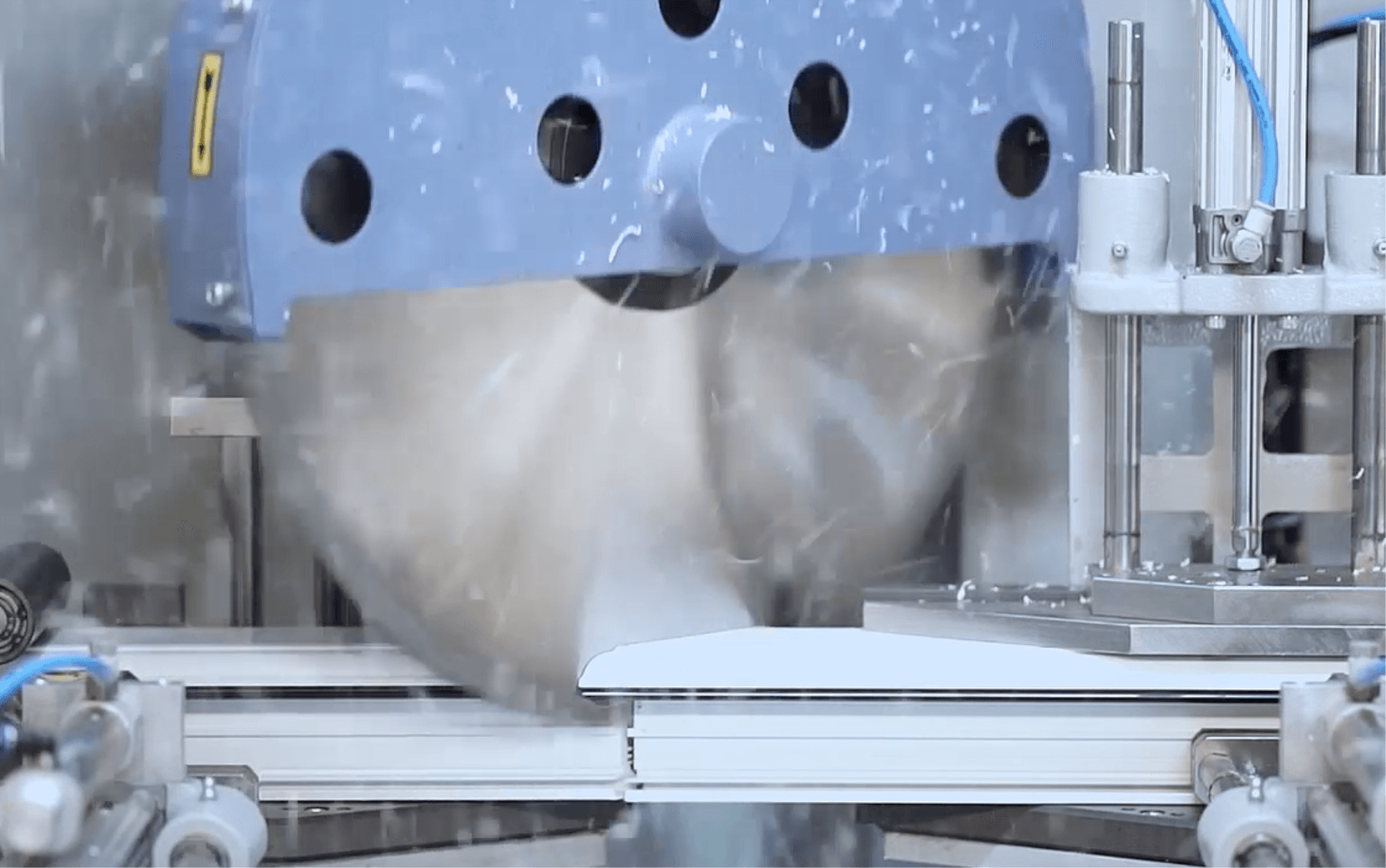

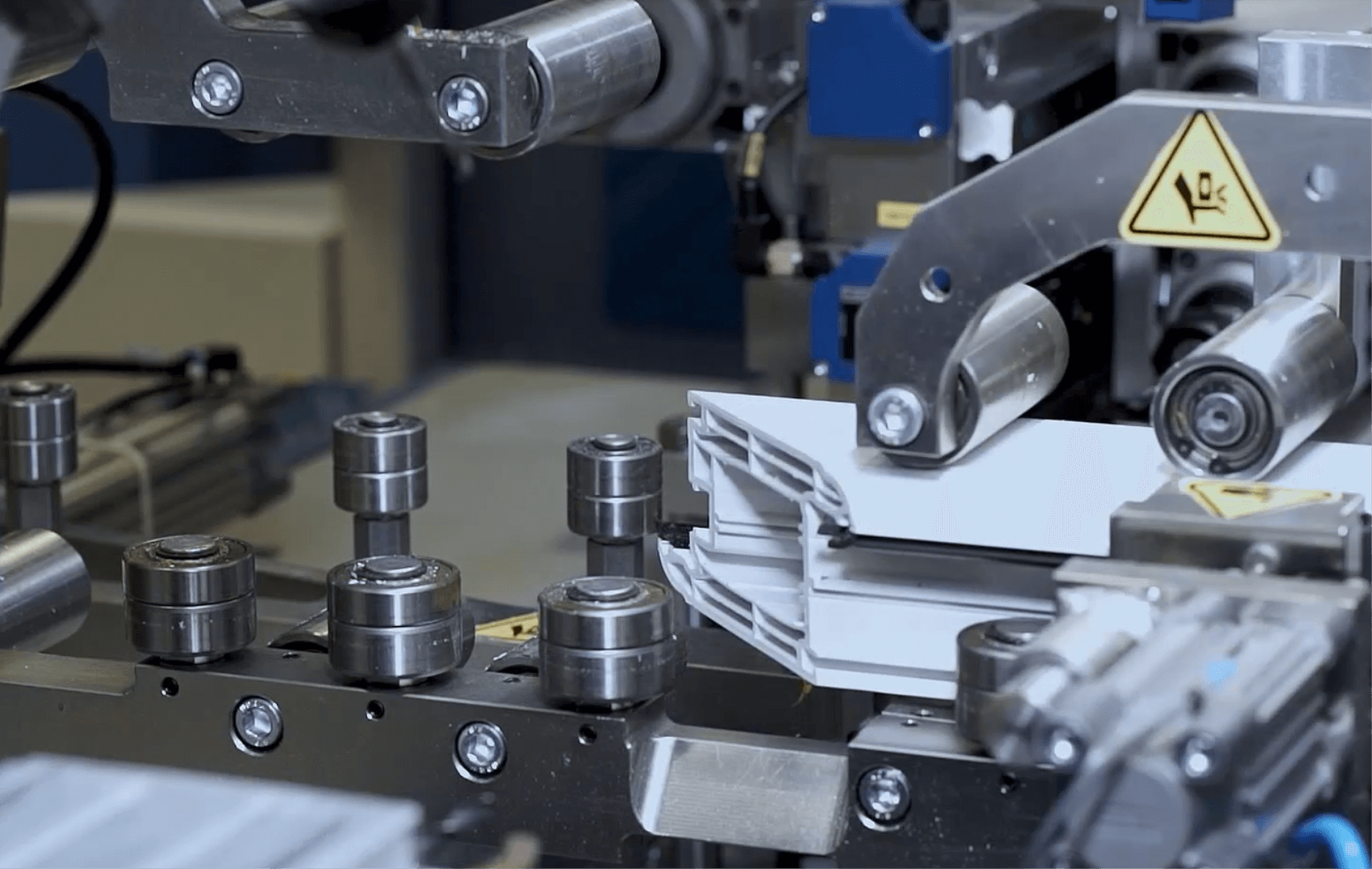

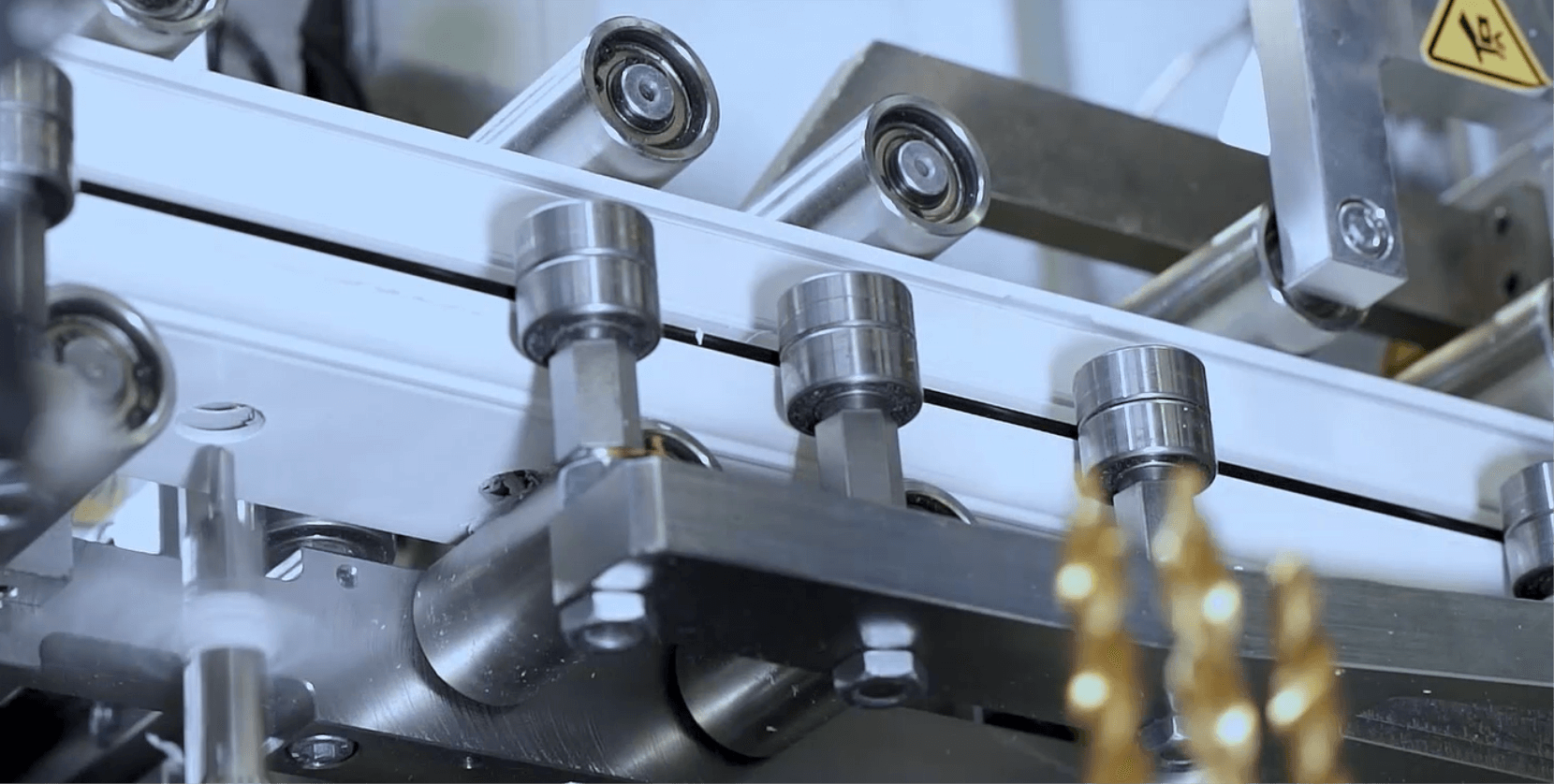

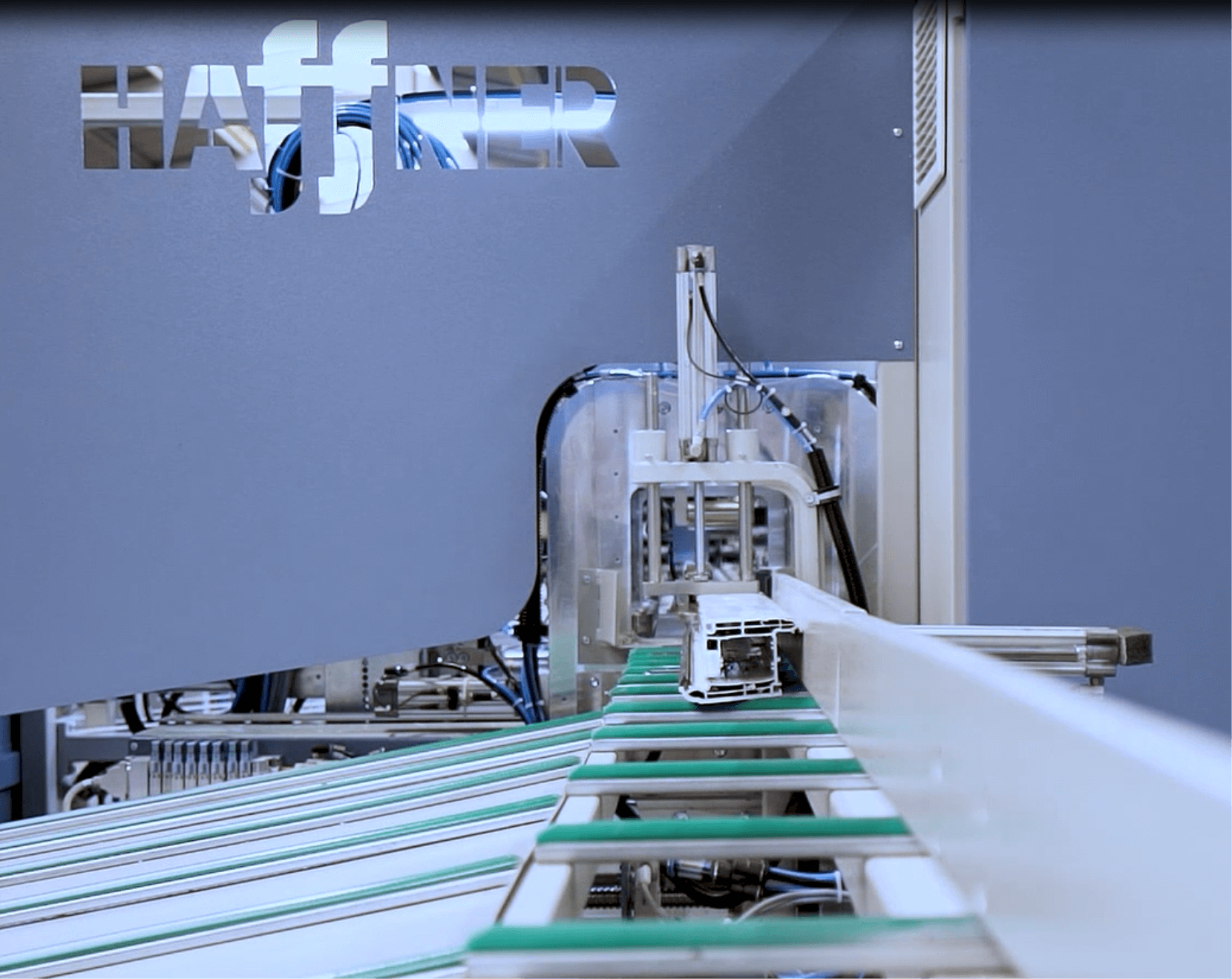

NR-242 Profile Machining Center; 3 milling and cutting stations are designed to work independently and sychronized and to perform all milling, drilling, reinforcement steel screwing, routing and marking operations on PVC profiles in a single computer controlled machine. With the SCREW INSERTION FUNCTIONALITY INTEGRATED DIRECTLY IN THE TOOL RING, THE NR-242 can handle the work of several operators and machines. This system can be designed for most Tilt and Turn Windows Systems.

Overview

- All sawing, routing, drilling, reinforcement steel screwing, marking operations on PVC profiles are grouped in one machine controlled by computer

- Stacking of 10 profiles (max. 6,5 m length)

- Manual barcode labeling system

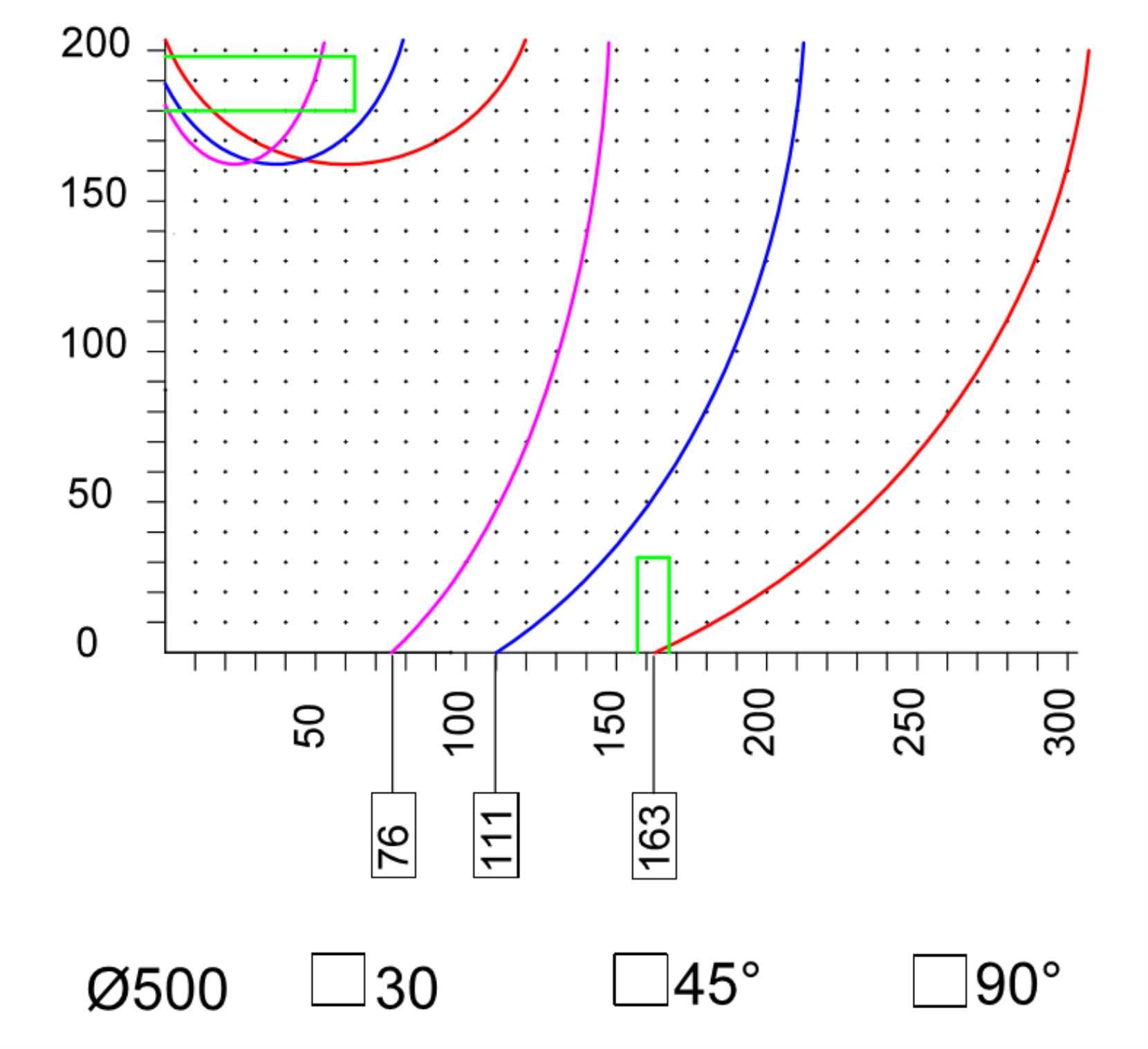

- Servo controlled automatic swing of the saw to all angles between 30° and 150° with 0.1° accuracy

- Drain slot routing, drilling and routing at variable angles

- Automatic screwing of reinforcement steels

- Drilling of fixation, triple handle and hinge holes together with the reinforcement steel

- Waste profiles longer than 500 mm can be re-processed

- 19” touchscreen enables easy control of the machine

- High performance industrial PC works between 0°C – 55°C without a fan

- Full integration with various window and door production software

- Safe production with 3D crash and fault control system developed by Haffner software engineering

- All error messages can be monitored from the screen

- Online connection to the entire system, remote detection of malfunctions and maintenance

- Automatic conveyor belt system to transport scrap profiles to waste container

- Data transfer is available via network connection or USB interface

- Central lubrication system eases maintenance

Available Options

- End milling of transom profiles with two blade sets for two different profile cross sections

Video Demo & Application

Specs & Sizing

Electrical rating: 400 V, 3ph, 50-60 Hz

Motor power: 30 kW, 80A

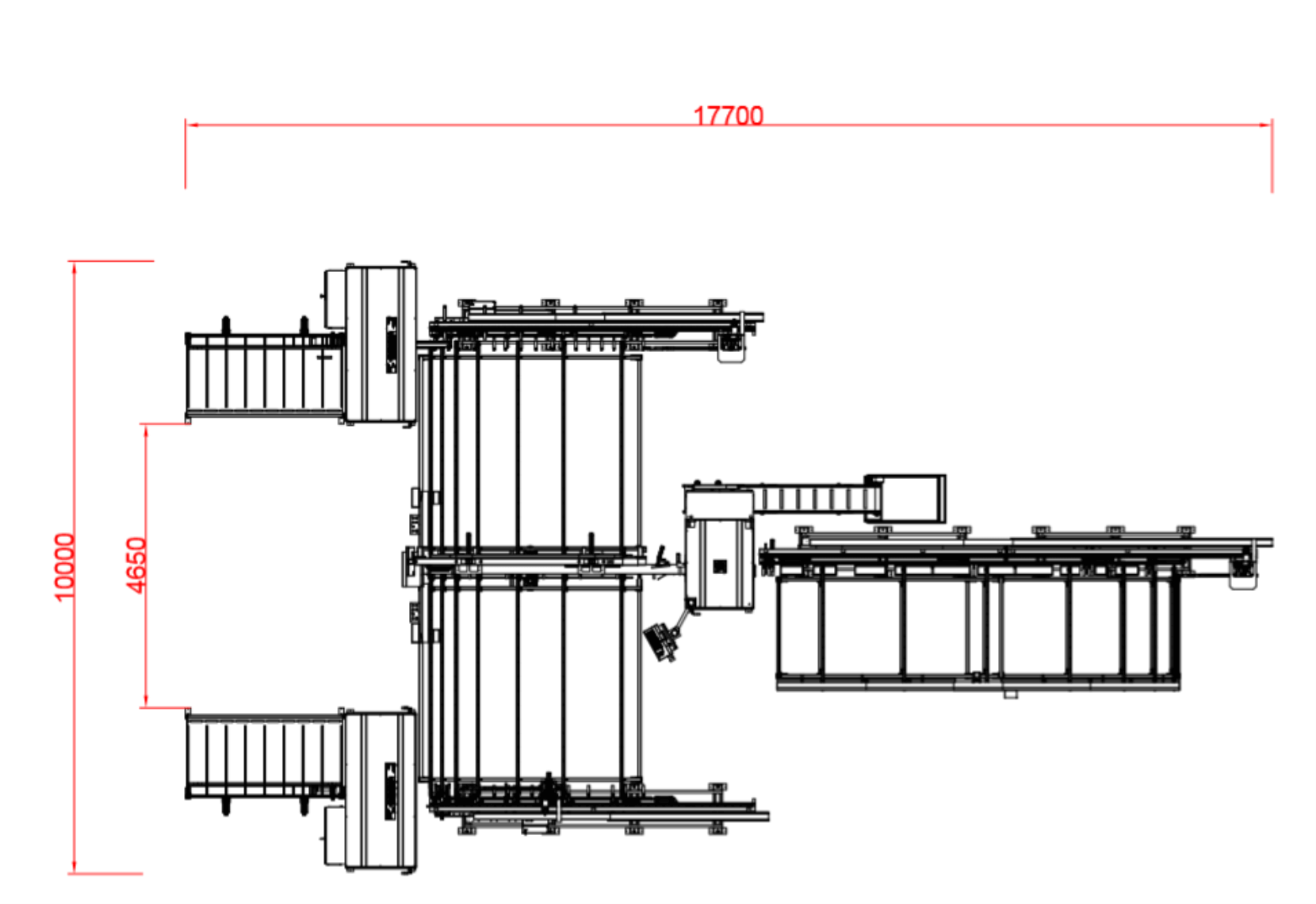

Saw diameter: Ø 500 mm.

Max. profile height: 140 mm.

Min. profile height: 35 mm.

Max. profile width: 130 mm.

Min. profile width: 35 mm.

Max. length of raw profile: 6,500 mm.

Max. profile machining length: 3,500 mm.

Min. profile processing length: 330 mm.

Air pressure: 6-8 bar

Air consumption: 1,200 lt / min

Machine height: 2,350 mm.

Machine length: 18,000 mm.

Machine width: 10,000 mm.

Machine weight: 10,800 kg.

Gallery