SBA-2 120 E PVC Profile Processing Center

SBA-2

SBA-2 Profile Processing Center is designed to perform all cutting, milling, drilling and marking operations on PVC profiles in a single station, as well as special cutting operations such as V-cut, Y-cut and arrowhead cutting on a single computer controlled machine. The processes performed on 3 different machines (cutting, copy milling, water evacuation) with 3 operators are performed in a single machine. The production speed and quality standardization are ensured while labor resources are maximized.

Overview

- Profile independent single bar operation

- Modular construction ensures optimum flexibility

- High precision servo drives for speed and accuracy

- 10 Bar loading system

- 6.5 meter working bar length

- Programmable Gripper Unit with zero point positioning

- 12 Tool dedicated routing station with option for special tooling if required

- Cutting Station with 3 x 550mm sawblades for greater accuracy and speed

- Automatic profile support system to avoid rolling of profiles

- Off load conveyor with independent operation

- Zebra label printer

- Waste conveyor for off cuts

- High performance 15” touch industrial PC works without a fan between 0°C – 55°C

- Machine with full mechanical guarding around all sides

- Scrap Evacuation Conveyor System

- Extraction system for saw unit

- All error messages can be monitored from the screen

- Data transfer is available via network connection or USB interface

Available Options

- Automatic Central Lubrication System

- Cooling Unit For Electrical Cabinet

Specs & Sizing

Operating voltage

220 V or 440 V, 3 ph

220 V or 440 V, 3 ph

Frequency

60 Hz

60 Hz

Total power

20 Hp

15 kW

Current

40 Amp

40 Amp

Air pressure

90-120 psi

6-8 Bar

Air consumption

CFM

Lt /min

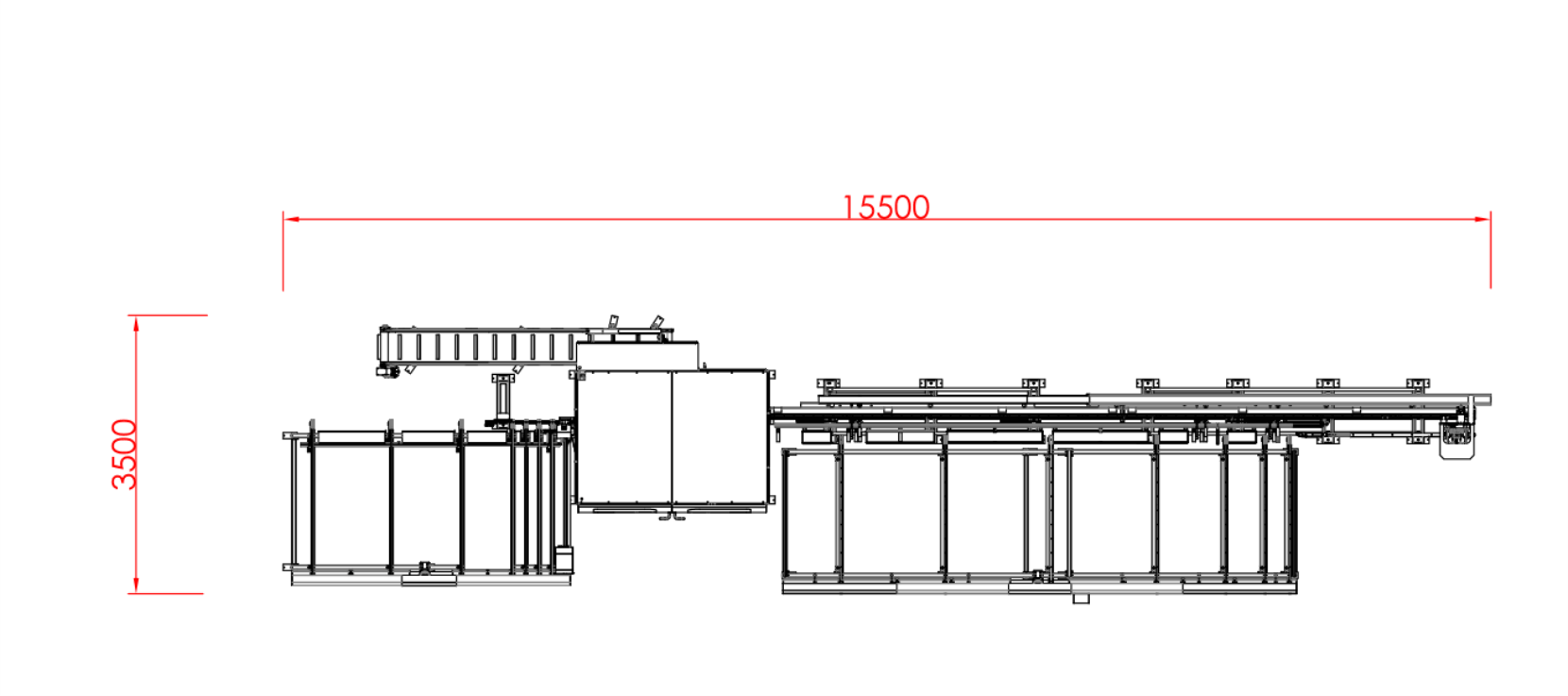

Machine length

610 inch

15500 mm

Machine width

138 inch

3500 mm

Machine height

87 inch

2210 mm

Machine weight

11020 lb

5000 kg

Max. profile processing length

256 inch = 21.3 feet

6500 mm

Min. profile processing length

15.75 inch

400 mm

Min. profile width

1.58 inch

40 mm

Max. profile width

5.1 inch

130 mm

Min. profile cutting height

1.78 inch

45 mm

Max. profile cutting height

5.5 inch

140 mm

Max. raw profile length

256 inch

6500 mm

Gallery