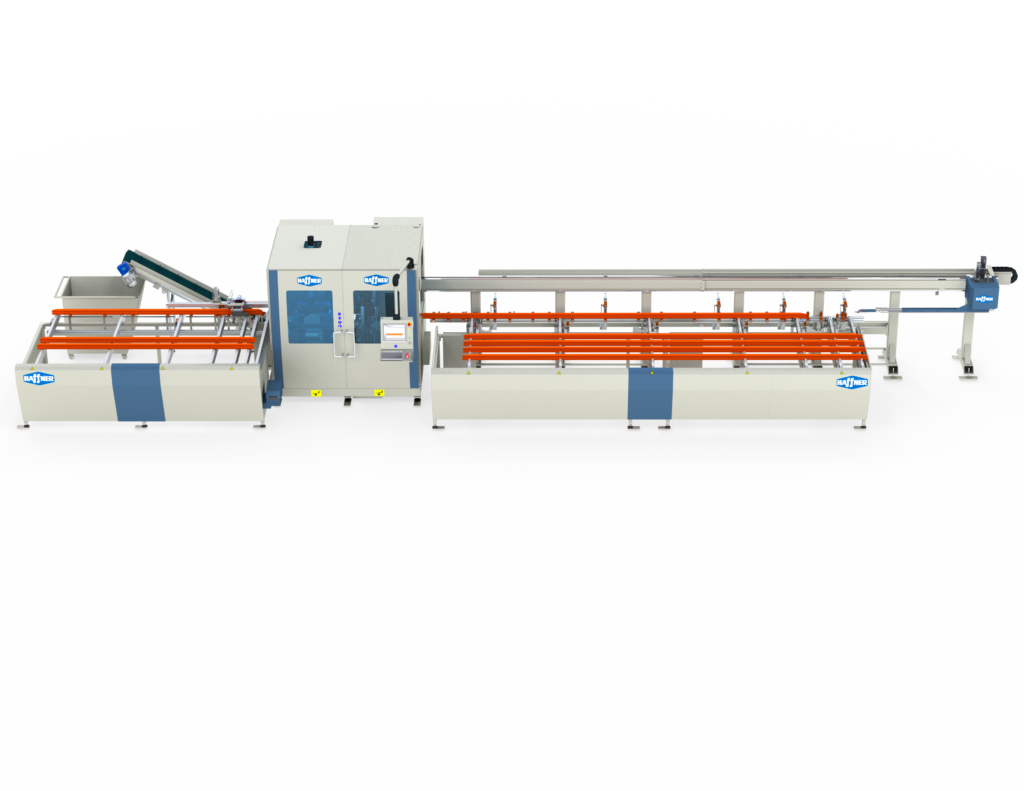

SC-220/40 PVC Profile Processing Center

SC-220/40 SC-220/90

All sawing, routing, drilling and marking processes on PVC profiles are performed in one computer controlled machine. The processes carried out on 3 different machines (cutting, copy milling, routing drain slot) with 3 operators are converged in a single machine, while the production speed and quality standardization are ensured and labor resources are maximized.

Overview

- All sawing, milling, drilling and marking operations on PVC profiles are grouped in one machine controlled by a computer

- Stacking of 10 profiles (max 6,5 m length)

- Automatic cutting in all angles between 30° and 150° with accuracy of 0,1° by means of servo motors

- Work in high speed and precision due to 7 axis controlled by servo motors

- Ability to open drain slot routing, drilling and milling at variable angles

- Automatic conveyor belt system to transport scrap profile to the waste container

- Opens barrel, mirror and handle holes at door profiles simultaneously to increase the production speed by using an extra servo motor

- Notifies user against incorrect loaded profile due to profile recognition system

- Performs all operations precisely by the 7 tools on the milling group

- Manual barcode labelling system which works integrated with CNC lines

- 15” touch screen monitor

- Industrial PC with Windows 10 which works between 0°C – 55°C without fan

- Ability to work with the data input from different window production software giving minimum wastage

- Safe production facility via 3D collision and error control system developed by Haffner software engineering. Visible on screen with interface program.

- Problem identification, solution and servicing by means of remote connections

- Data transfer is available via network and connection or USB interface

- Ability to back-up daily data on internal storage unit

- Shift monitoring system enables all operations to be controlled daily, weekly, monthly and yearly

- Central lubrication system to ease the machine maintenance

Available Options

- DV-410 Screw Unit can be added as an option for Reinforcement profile screwing

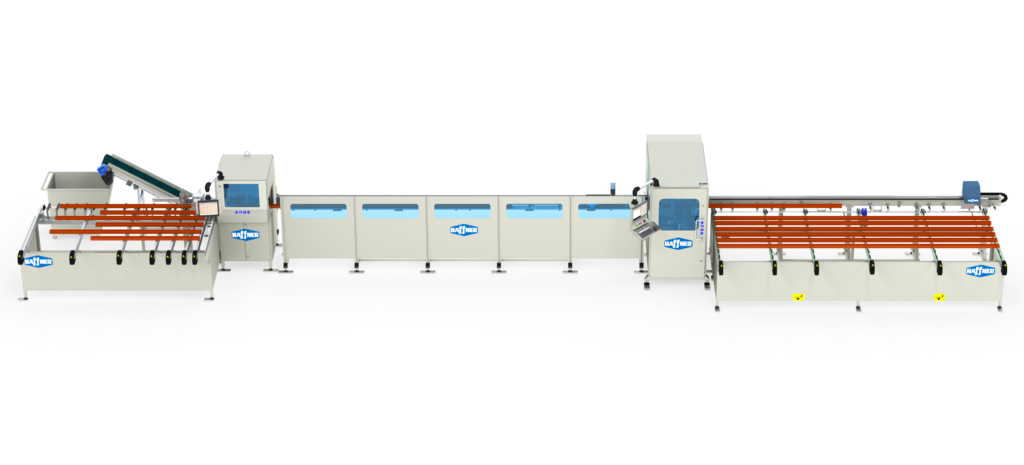

SC-220/90

- Back saw with 500mm diameter, with angle adjustment for window sill profiles (+7° and -7°),

- Max. profile processing width: 210mm

Video Demo & Application

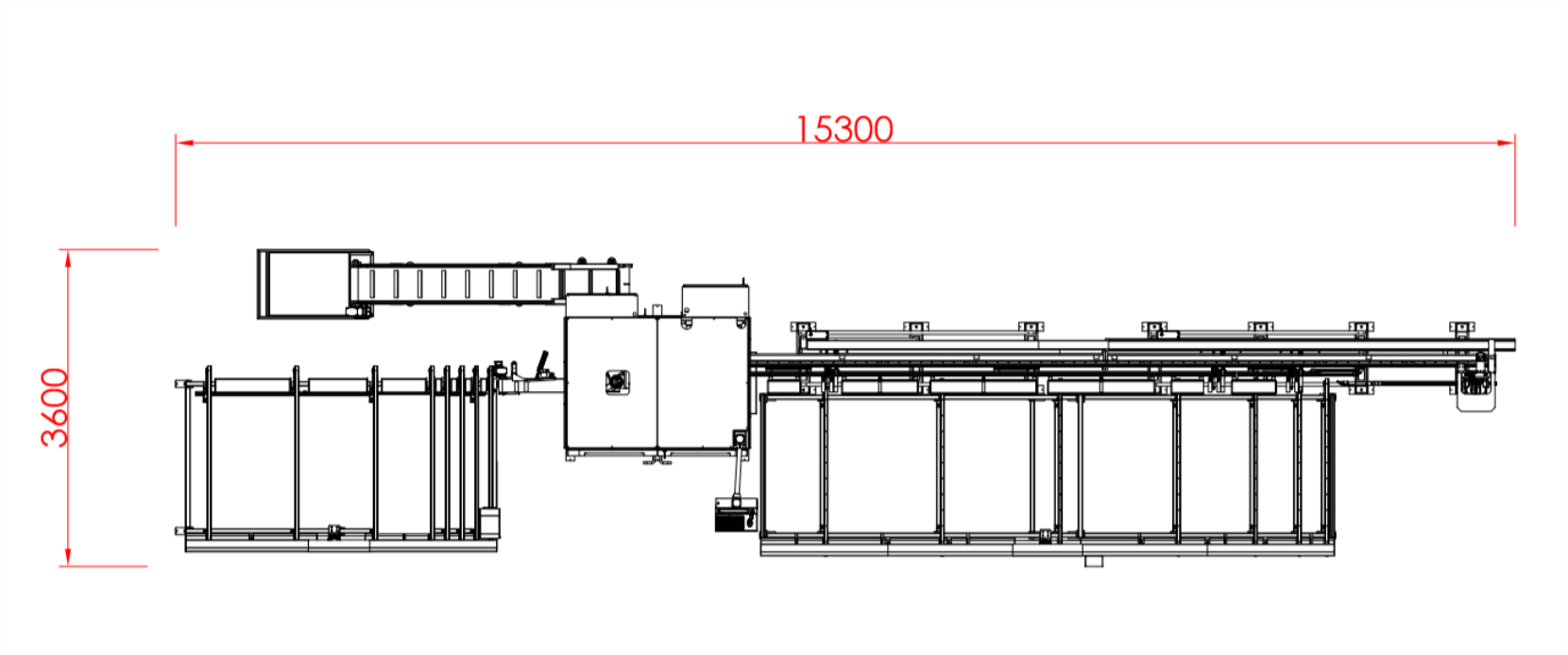

Specs & Sizing

Electrical Rating: 400 VAC, 3 ph, ground and neutral separate

Total Power: 15 kW, 37,5 A

Max. Profile Processing Height: 140 mm

Min. Profile Processing Height: 35 mm

Max. Profile Processing Width: 130 mm

Min. Profile Processing Width: 35 mm

Max. Length of raw profile: 6.500 mm

Max. Profile Processing Length: 6,500 mm

Min. Profile Processing Length: 330 mm

Air Pressure: 6-8 bar

Air Consumption: 608 l / min.

Machine Height: 2360mm

Machine Length: 15.300 mm

Machine Width: 3.600 mm

Machine Weight: 3.650 kg

Gallery