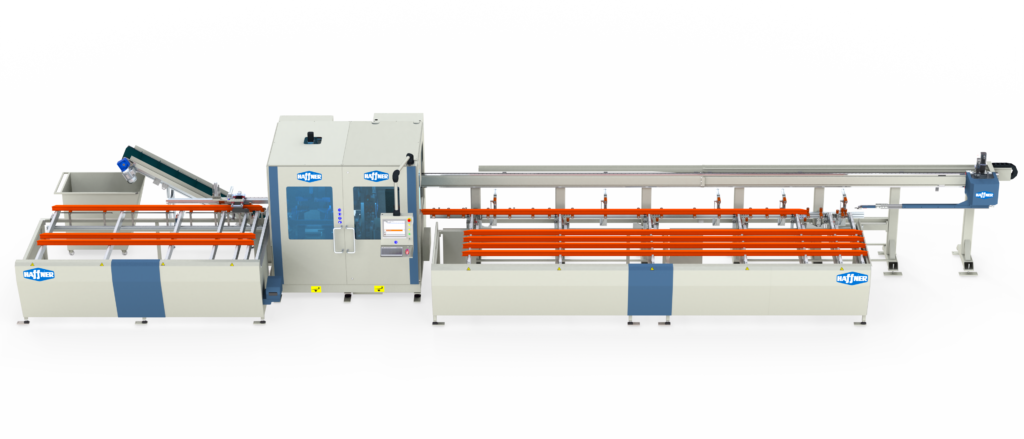

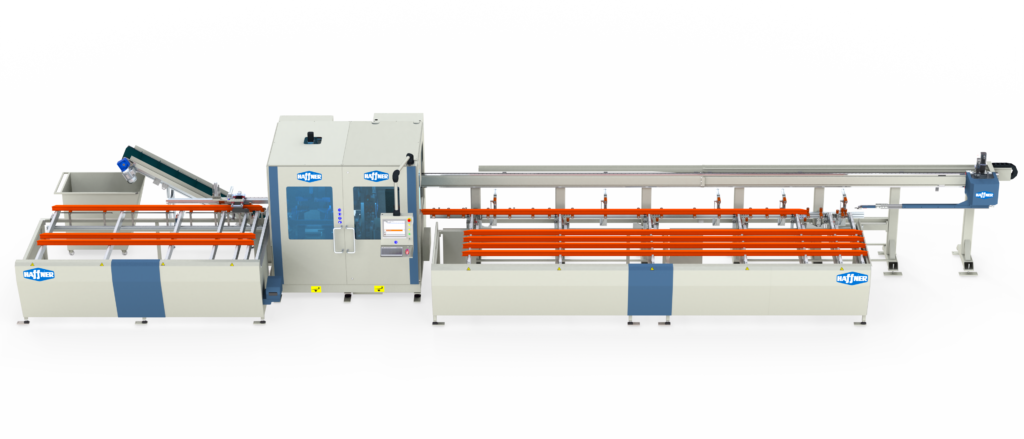

AL-220/70 AL-220/80 Aluminum Profile Processing Center

AL-220/70 AL-220/80

AL-220/70 AL-220/80 Profile Machining Center is designed to perform all cutting, milling, drilling and marking operations on aluminum profiles in a single machine with computer control. The operations performed on more than one cutting machine are collected in a single machine, ensuring production speed and quality standardization, at the same time, maximizing labor resources.

Overview

- All cutting, notching, milling, drilling and marking operations on the aluminum profiles have been integrated together in a single computer-controlled machine

- 7 profile stacking possibility, 500 mm (19.69 in.) saw diameter (Max. raw profile length 7 meter (22.96 ft.))

- Automatic horizontal/vertical positionable gripper

- Able to make automatic cutting at all angles between 45° and 135° in 0.1° increments via servo motors

- Able to work with high speed and sensitivity due to 9 axes controlled by servo motors

- Feature able to perform opening, drilling and milling operations of angled water drainage channels

- Able to carry remaining waste parts to the waste chamber with automatic conveyor system

- Increased production speed with simultaneous machining of barrel, mirror and arm on doors

- Able to perform all operations sensitively with an 12-tool set in the milling group

- 15” Touch screen

- High performance industrial PC working between 0°C – 55°C (32°F – 131°F) without an additional fan

- Working with production data input from different window production software programs to allow minimum waste

- All error messages can be monitored from the screen

- Able to provide service and troubleshooting with remote connection method

- Operating system ensures maximum safety measures against virus spreading and user errors by cleaning unnecessary processes of the last login automatically at every opening/closing of the machine

- Remote network connection or data transfer via USB

- Possibility to perform daily back up operation to internal back up unit automatically

- Daily, weekly, monthly and annually production control with shift control system

- Central lubricating system that facilitates machine maintenance

- Operating and Maintenance manual

- Tool Kit

AL-220/80

- With servo-controlled cutting, saws can be positioned automatically according to the height of the profile for fast and rigid cutting

- 0°C – 360° rotatable servo controlled gripper

- Punch group, screwing unit

- Able to perform all operations sensitively with 12 tool set being in the milling group

- Saw blade diameter: 600mm

- Max. Profile Processing Width: 225 mm (8.85 in.)

- Max. Profile Processing Height: 185 mm (7.28)

Video Demo & Application

Specs & Sizing

Power Supply: 400 VAC, 3 ph., ground and neutral separate

Connected Load: 20 kW (56.60, 33.96, 28.30 or 23.62 F.L.A. (calculated))

Minimum Profile Processing Height: 35 mm (1.37 in.)

Maximum Profile Processing Height: 160 mm (6.29 in.)

Maximum Profile Processing Width: 130 mm (5.11 in.)

Minimum Raw Profile Length: 1,000 mm (39.37 in.)

Maximum Raw Profile Length: 6,500 mm (255.90 in.)

Minimum Profile Processing Length: 350 mm (13.77 in.)

Maximum Profile Processing Length: 6,500 mm (255.90 in.)

Working Air Pressure: 6-8 bar (90-120 psi)

Air Consumption: 750 l/min. (26.48 cfm)

Machine Height: 2,500 mm (98.42 in.)

Machine Length: 15,300 mm (602.36 in.)

Machine Width: 3,600 mm (141.73 in.)

Machine Weight: 5,700 kg (12,570 lbs.)

Gallery