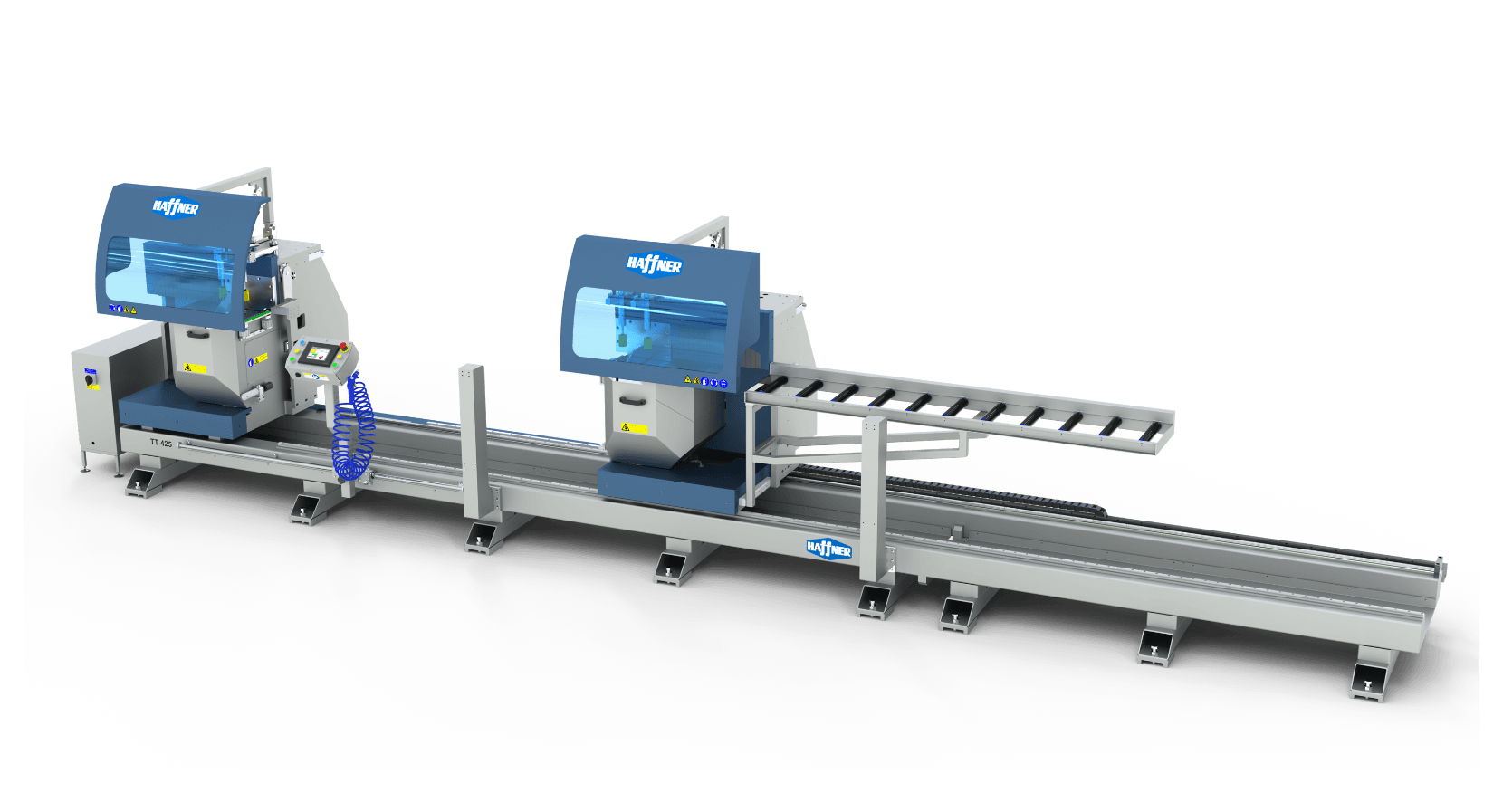

TT- 425 Double Mitre Saw

TT- 425

TT-425 Double Head Cutting Machine can easily cut aluminum and PVC profiles with 2 saws each with a 450 mm diameter, works with the “undercut” principle and adjustable saw output speed. Parts up to 6000 mm can be cut automatically. It has a strong construction specially designed for best cutting quality, length and angle precision.

Overview

- Machine bed made of steel sheet, cutting length 4000 mm standard, 6000 mm and 7500 mm optional.

- Solid cast construction for length and angle accuracy.

- Length and cutting accuracy due to strong construction and linear bearing system.

- Position accuracy possible with angle deviations is less than 0.1°.

- Pivoting range with digital angle display.

- Chop and oversize length cuts (min: 4 mm – max: 7.500 mm).

- Profile lifting bars.

- Automatic closing safety hood to protect the employee.

- 2 standard vertical clamping system and 1 optional horizontal clamping system to ensure optimum profile fixing.

- Data transfer by means of Network connection or USB.

- Item number, length dimensions, angles and quantities can be programmed on the control panel (2.000 x 10: able to cut in different program).

Available Options

- Machine can be produced 6000 mm and 7500 mm in length upon request

- Hydro-pneumatic saw feed

- Label printer

- Transom stop and lead-cut stop

- Dust and chips extraction system

- Roller conveyors

Specs & Sizing

Minimum cutting length: 90° 350 mm

Minimum cutting length tilted: 45° 350 mm

Pivoting range inwards 90°- 45° with accuracy up to 0.1°

Tilting range inwards pneumatically 90°- 45°

7.0″, 800 x 480 (WVGA) resolution

Two saw blades diameter: 450 mm

Saw blade speed: 2,800 rpm

Power supply: 230/400 V, 3~, 50 Hz

Power output per motor: 4 kW

Compressed air supply: 7 bar

Air consumption per working cycle 34 l without spraying, 60 l with spraying

Gallery