Need an ongoing partnership until the end of your buyer journey, not just a one-stop shop? No problem.

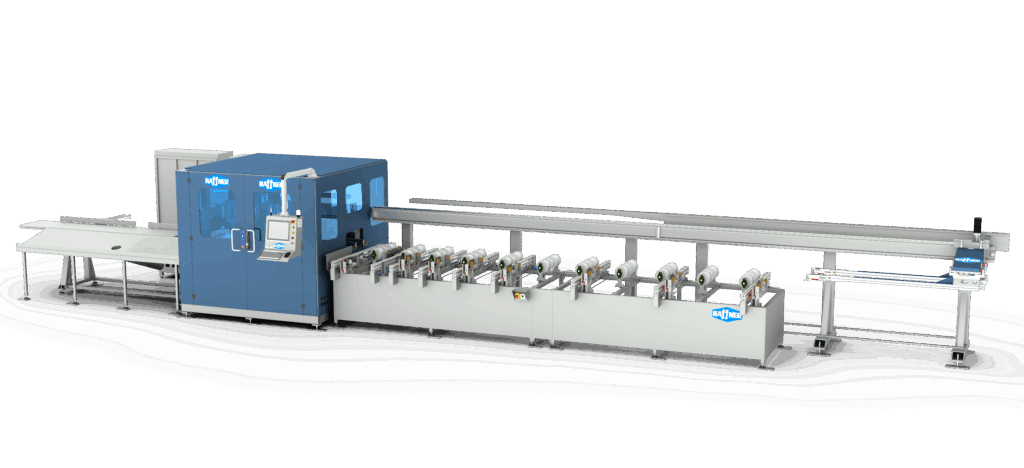

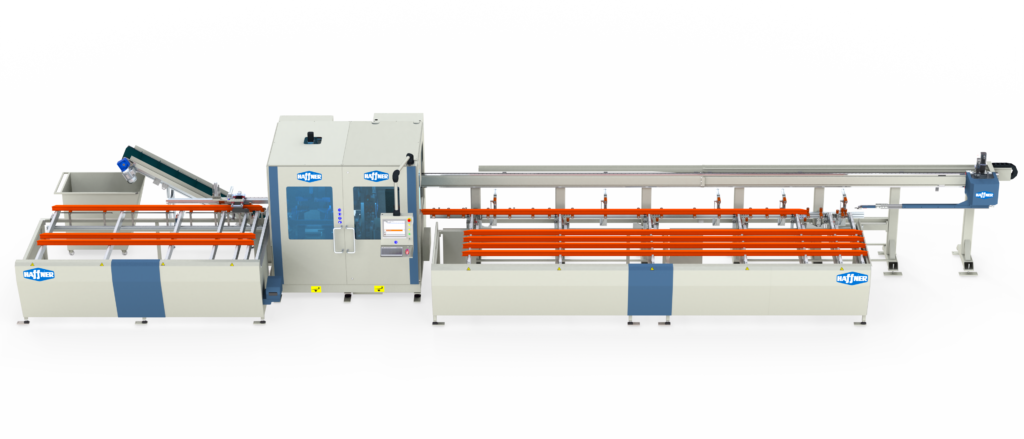

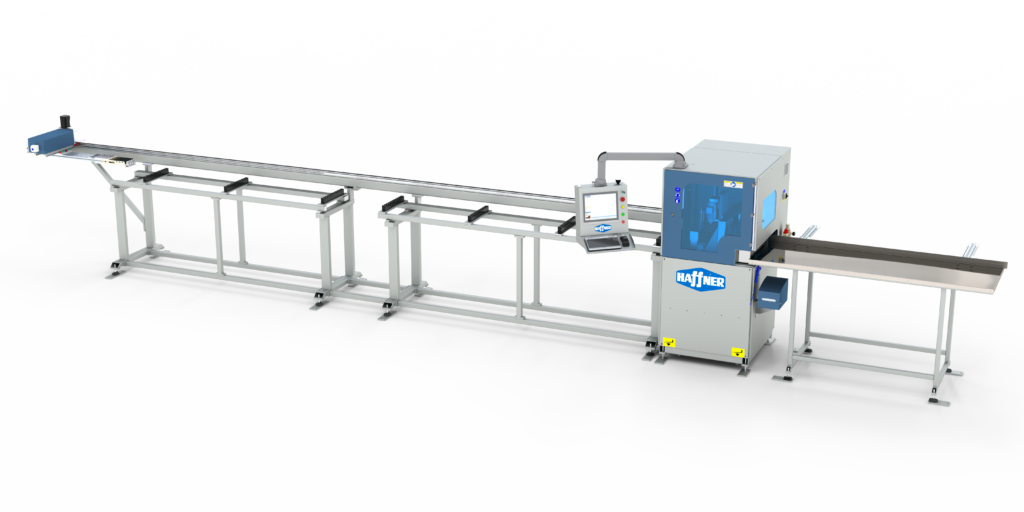

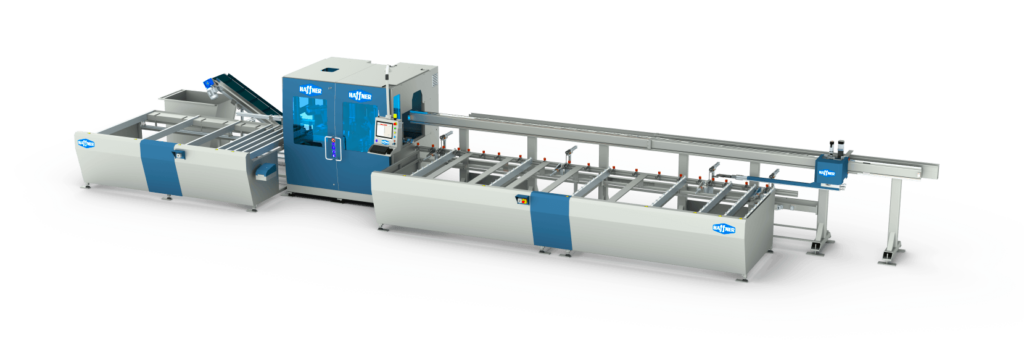

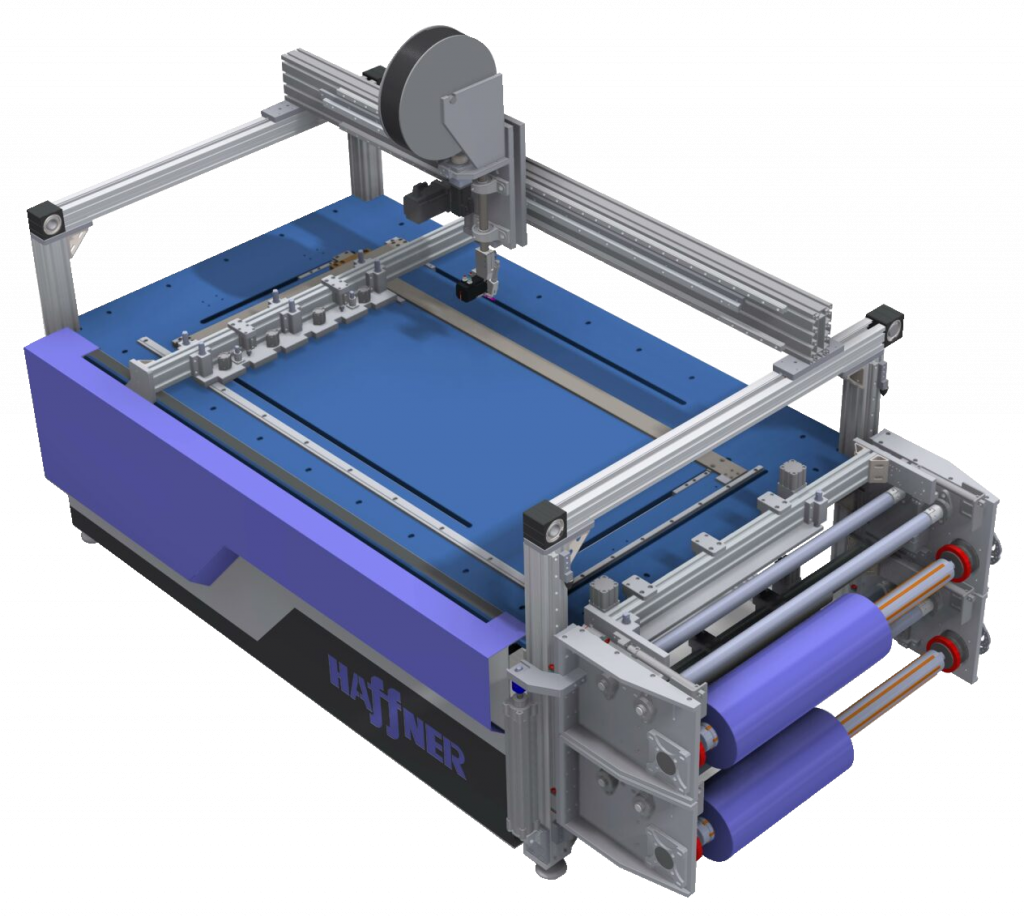

Haffner Machinery provides end‑to‑end production solutions for window and door manufacturers, combining advanced, smart machinery with a comprehensive, customer‑focused service model. Our approach emphasizes innovation, efficiency, and hands‑on support from the initial project review to installation, training, and ongoing monitoring.

Q&A with Haffner Machinery

What does Haffner’s design and deployment process look like?

Haffner guides each client through a structured, multi-phase process ensuring the right machinery is selected, tested, installed, and fully supported. The stages include:

- Client requirement review – A deep dive into your production line needs to determine optimal machine options.

- Commercial proposal & technical review – Development of a detailed capacity plan outlining data flow, machine profiles, outputs, and quantities.

- Factory build & acceptance testing – Customers participate in equipment testing in person or remotely.Installation & customer acceptance testing – Haffner technicians validate that actual performance aligns with the original capacity plan.

- Turnkey training – Certified technicians train your team and set up optional remote viewing capabilities.

Will Haffner customize machinery to my workflow?

Yes. Haffner’s approach emphasizes tailored solutions. The process begins with reviewing your specific line requirements and continues through factory acceptance testing to ensure machines match your exact production needs before they go live.

How does Haffner ensure quality and guarantee seamless integration into my shop floor?

Haffner invites customers to participate either in person or remotely as part of their phased order processing plan. And, after the machinery is built, our technical staff evaluates its production capacity compared to the original plan.

Does Haffner provide in‑person installation and training?

Yes. As part of Haffner’s deployment process, certified technicians travel onsite to install and set up your new machinery and verify that its performance meets your original capacity plan. After installation, we also provide turnkey in‑person training for your operators, ensuring your team is fully prepared to run the equipment confidently and efficiently.

What types of post-installation support does Haffner offer?

Haffner provides comprehensive after installation support, including:

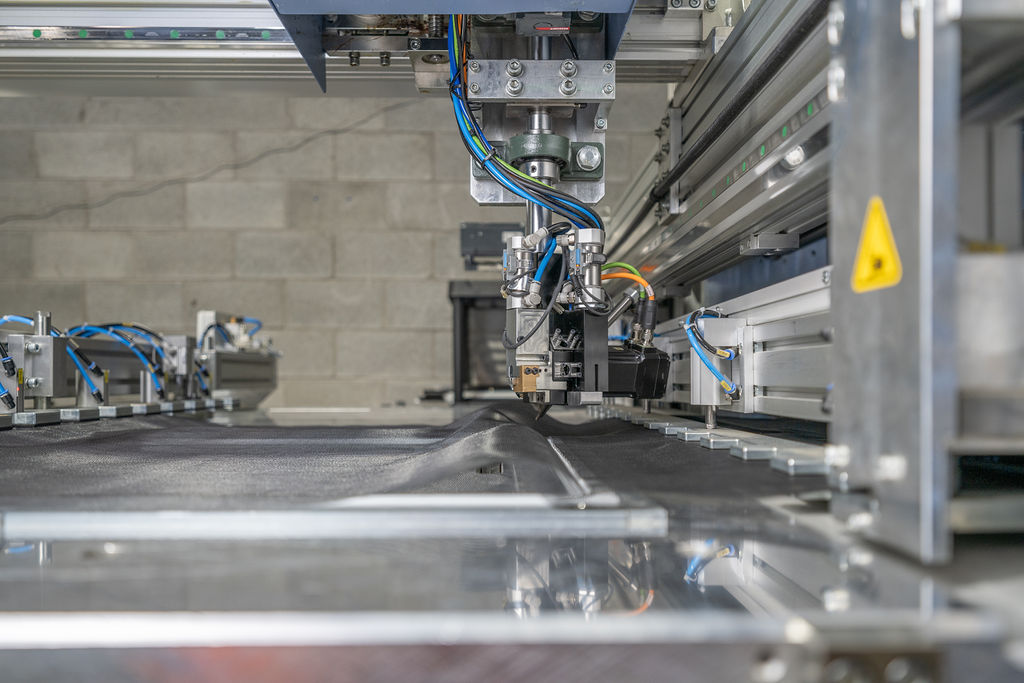

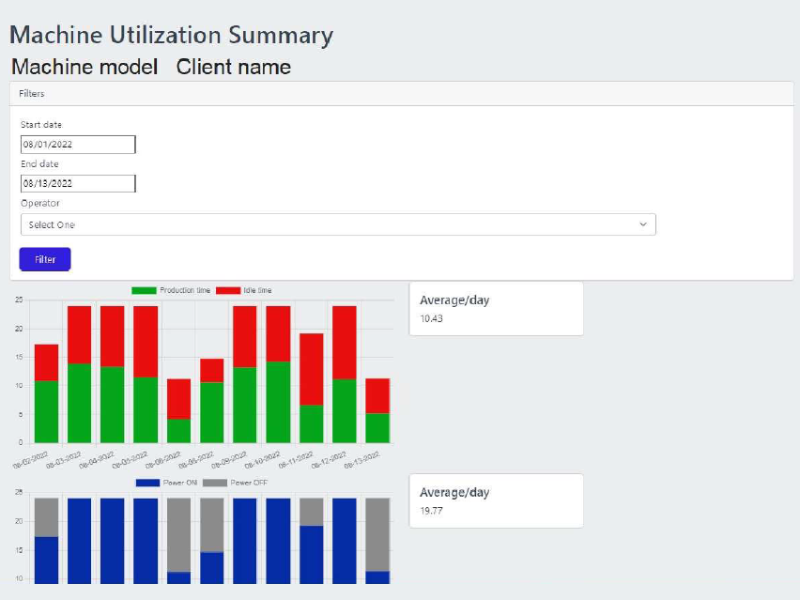

- Real-time monitoring via cloud-based software to optimize uptime and reduce bottlenecks.

- Remote viewing with video analytics to monitor machine performance.

- Engineering resources for integrations, troubleshooting, and ongoing optimizations.

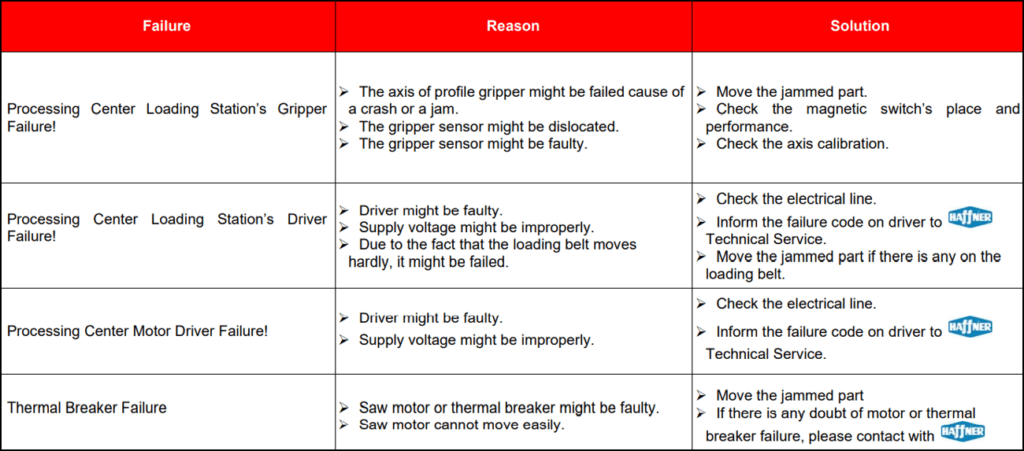

- Quick-response aftermarket service with available parts and labor support when needed.

How does real time monitoring work?

Haffner’s cloud-based monitoring software allows you to access your machine lines from anywhere, providing real-time data to reduce delays and maximize output. You can access the machines in real time with our Video on Demand Camera Monitoring system and the Haffner Machine Utilization App.

Remote viewing gives users video and analytic visibility into machine performance. It helps identify issues quickly and supports smooth production by allowing Haffner technicians to assist without requiring on-site visits.

Want a walk-through of our remote monitoring technology?

What engineering resources are available?

Haffner’s engineering team offers support from large-scale integrations to fine-tuned optimizations. We analyze your production needs and provide customized recommendations.

How fast is Haffner’s service response?

Haffner promotes rapid repair and parts availability to reduce downtime. Our integrated aftermarket support model doubles down on providing quick labor and components when issues arise.

Haffner’s service model is built around customer success, keeping in mind tailored solutions, transparent testing, installation, training, monitoring, and ongoing support. If you need high‑capacity production systems, continuous oversight, or rapid service response, our comprehensive approach ensures your factory is equipped for reliable, efficient, and scalable throughput.

Ready to partner with Haffner?

Contact our team to start your journey with us.