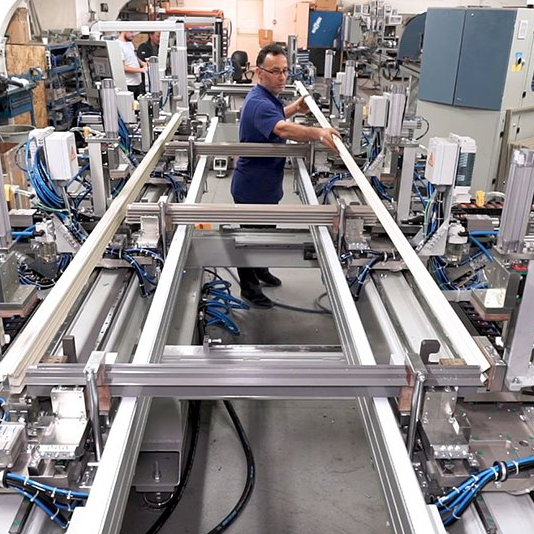

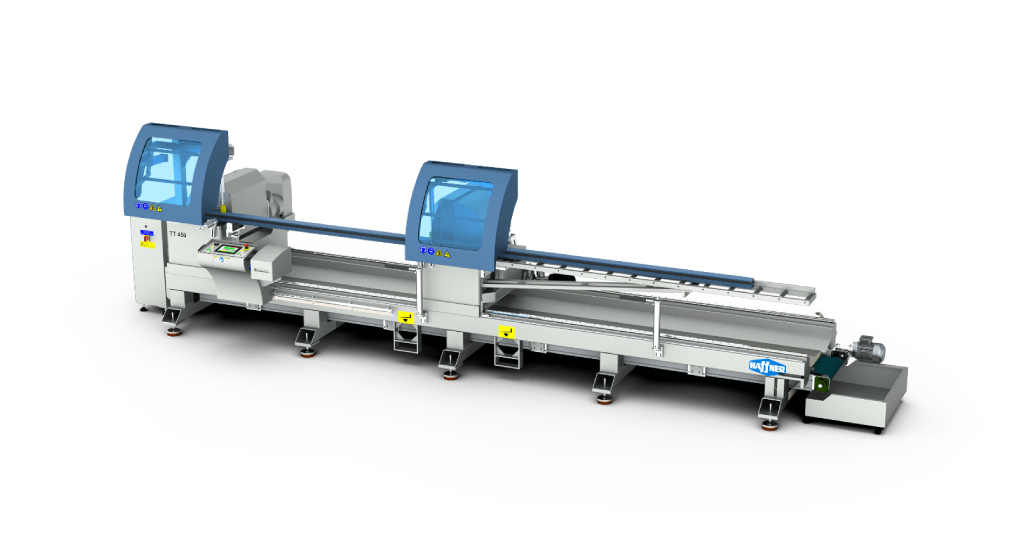

Haffner Machinery has upgraded a fenestration plant to move from manual operations to fully automated processes. Screen frames are now pressed together automatically at a throughput rate of 90 screens per hour with the innovative SAC-100 Automatic Screen Frame Assembly Machine. Window frames are automatically screwed together at a throughput rate averaging 1 minute per frame, in the same principle with the FAC-100 Frame Assembly Machine.

With the SC-220/70 programmed for multiple profiles, all milling, drilling and cutting is completed automatically requiring only 1 person to load and offload finished parts. Haffner optimized the space and minimizes labour to produce the highest quality frames and doors. The customer is satisfied with the outcome and continues a partnership, expanding their Haffner machinery acquisitions further.

Post-installation service: Haffner provides camera monitoring remotely by Haffner Service Manager. Technicians are on standby to assist in real time via software remote access and camera access, as well as on site servicing.