October was a month of big moves and bold innovations at Haffner Machinery. From welcoming a seasoned industry leader to gearing up for the year’s biggest event—GlassBuild America—we’ve been busy shaping the future of fenestration automation.

New Hire Announcement: Phil Shrider

We’re excited to welcome Phil Shrider as Haffner Machinery’s new Director of Application Engineering! Phil brings a diverse range of experience in window and door manufacturing, having successfully managed existing facilities and built two greenfield factories from the ground up. His background spans:

- Project Management & Layouts – Helping customers design efficient workflows and optimize plant layouts.

- Process Mapping & Business Case Development – Building strong ROI strategies for automation investments.

- Preventative Maintenance & Root Cause Analysis – Ensuring long-term reliability and minimizing downtime.

Phil understands the challenges manufacturers face today, from labor shortages to tight payback expectations. As Phil says:

“Most manufacturers expect a two-year payback period for equipment. I’m looking forward to introducing transformative automation lines and helping customers anticipate and head off hiccups to achieve a faster payback.”

Ramp up to GlassBuild America 2025

GlassBuild America was held at the beginning of November. Haffner Machinery showcases the next generation of automation solutions.

What’s Happened at Our Booth?

- Live Demos of Eight Advanced Systems – Attendees saw our advanced machinery in action, from screen assembly to profile processing.

- Meet Our Experts – Stephen Kucer, President of Haffner Machinery, and our team of experts showcased how custom solutions can transform your operations.

- Explore Solutions for Labor Challenges – We explored how automation can boost throughput, reduce errors, and improve efficiency.

Featured Systems at Our Booth:

- DMC-055 PVC Profile Machining Center – Double-load capability for simultaneous processing of two individual profiles at the same time, maximizing throughput.

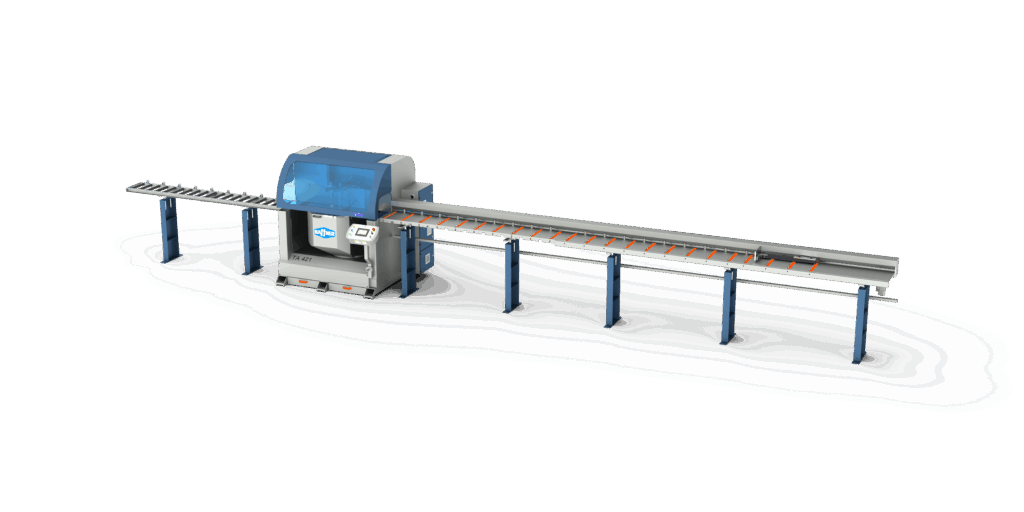

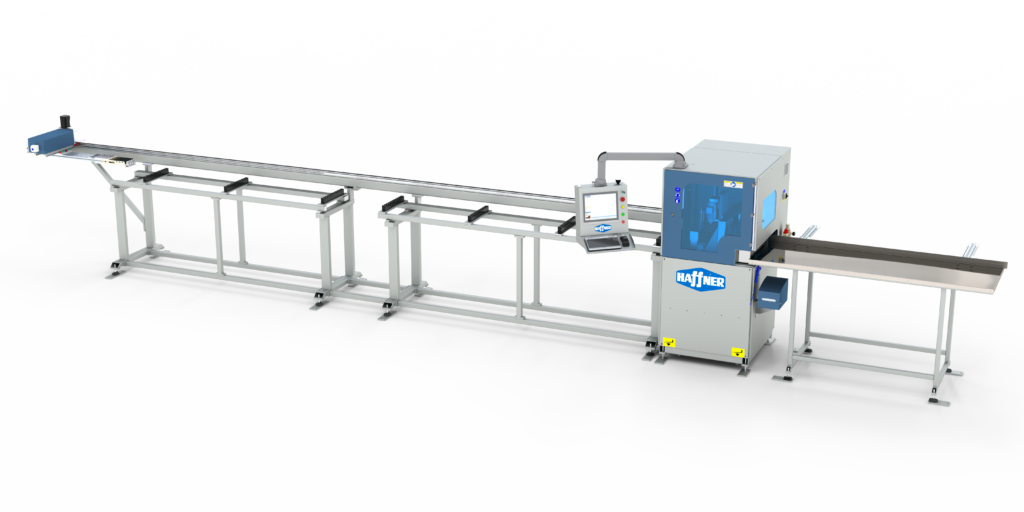

- TA-421 Automatic Single Mitre Saw – High-accuracy programmable cuts for aluminum profiles.

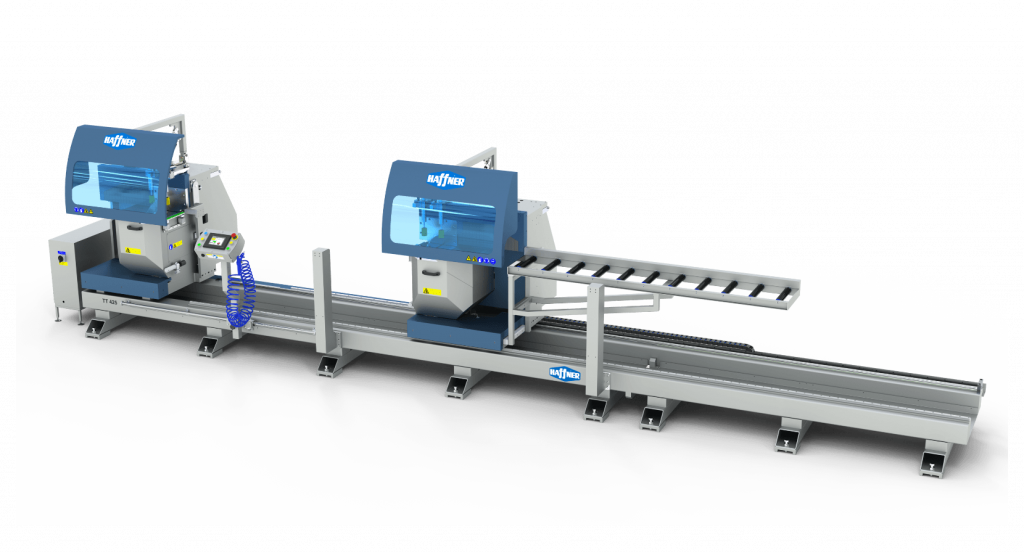

- TT-425 Double Mitre Saw – Versatile undercut technology for clean angles in aluminum and PVC.

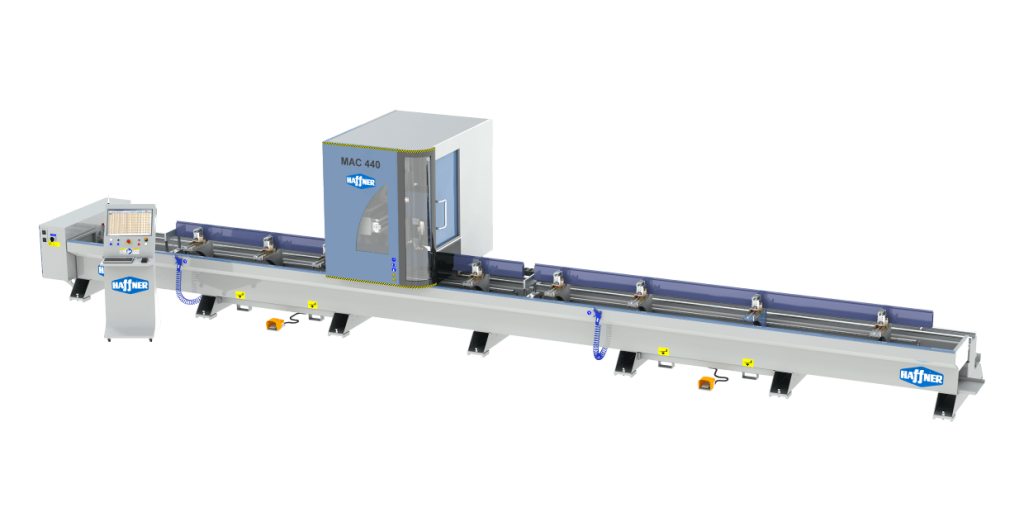

- MAC-340 & MAC-440 Aluminum Profile Processing Centers – Multi-step CNC machining with automatic tool changes for complex profiles.

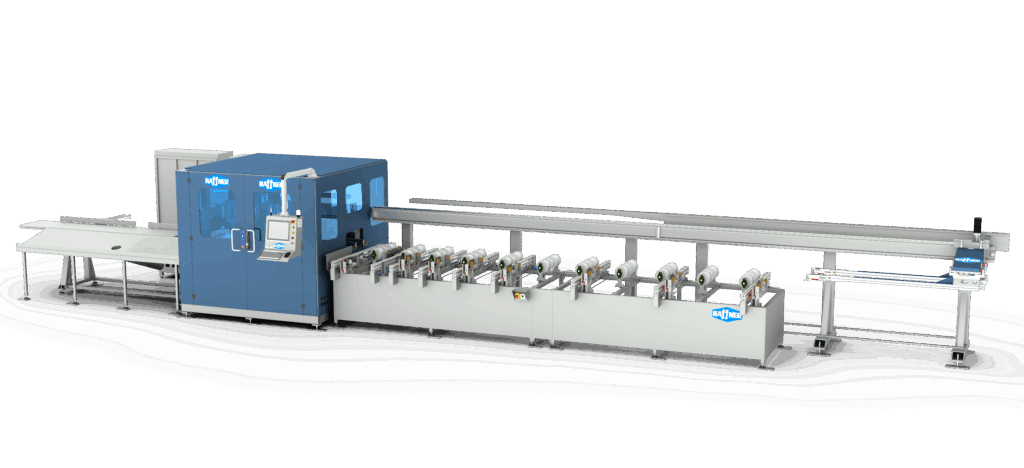

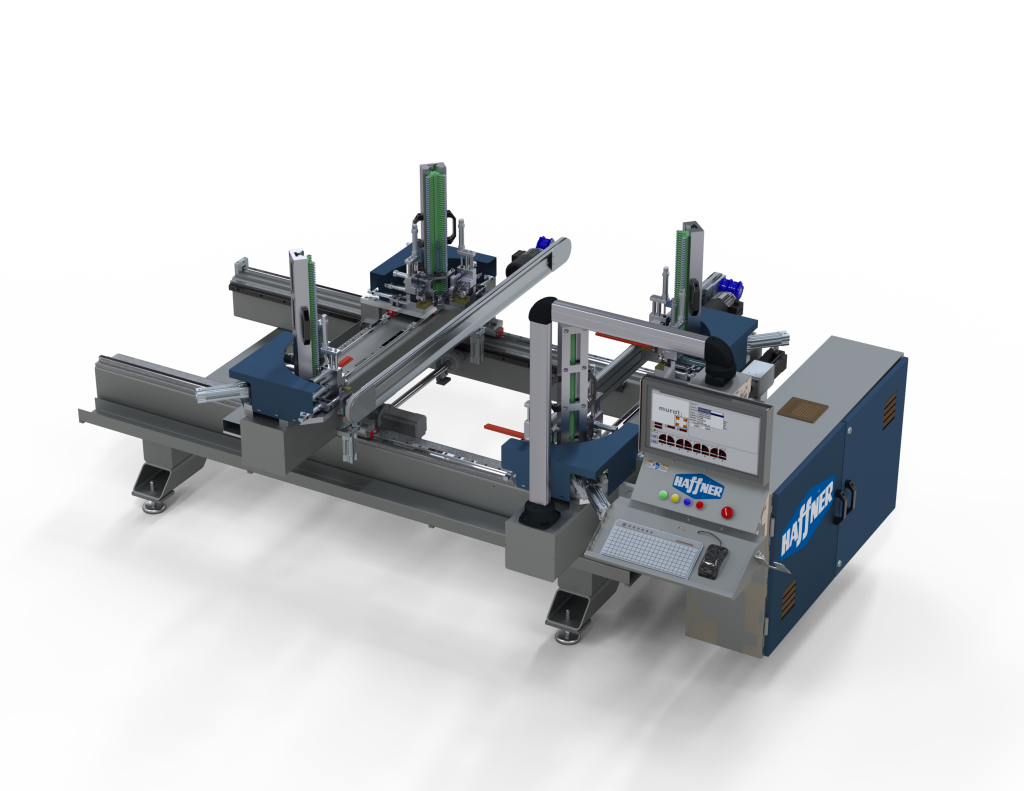

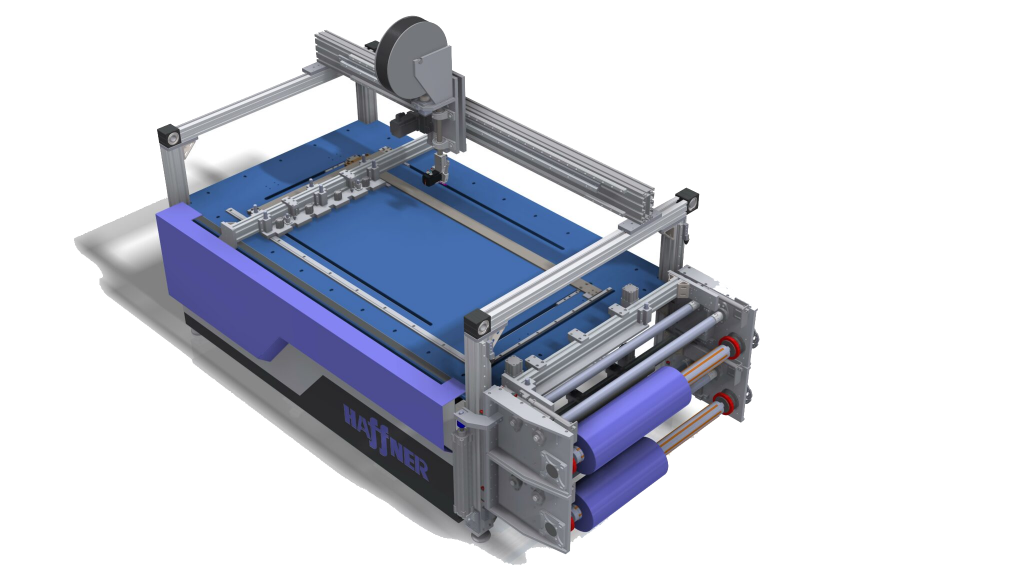

- AUTOSCREEN™ Trio – Fully automated screen assembly from cutting profile to frame assembly to screen insertion, now with patio door capability.

This year, we showed how we reshaped the window and door assembly with speed, precision, and automation.

Meet Tony C.

When you think of cutting-edge screen assembly, think of Tony C., Haffner’s Product Development Specialist. For five years, Tony has been the driving force behind automation innovation, blending mechanical expertise, software integration, and creative design to deliver solutions that redefine efficiency.

From troubleshooting machines remotely to installing advanced systems in Wisconsin and Australia, Tony’s work ensures customers worldwide experience seamless automation. His day-to-day includes:

- 3D Printing New Parts – Rapid prototyping for faster innovation.

- Testing Frames & Components – Guaranteeing precision and durability.

- Ensuring Flawless Installations – Smooth transitions from manual to automated processes.

Tony helped create the AUTOSCREEN™ product line, a fully automated solution for screen assembly that delivers speed, accuracy, and reliability. Here’s how it works:

- TA-144/30 – Automatic Aluminum Wedge Cutting Saw

- SAC-100 – Automated Screen Frame Assembly Machine

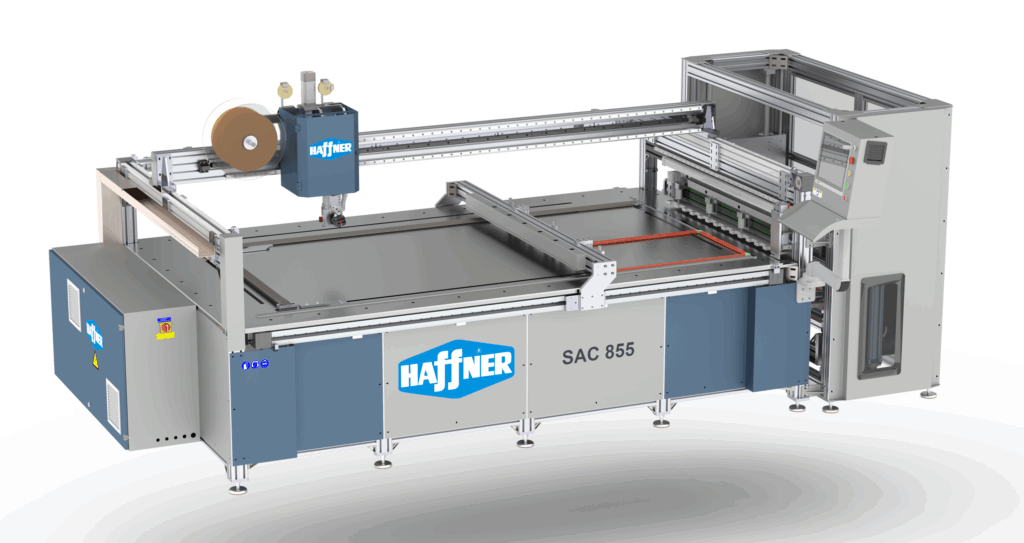

- SAC-850/855 – Automated Mesh/Spline Insertion & Trim Machines

This trio adapts to your needs while reducing labor costs and boosting throughput. Tony and the team stay with you every step of the way—from installation to training—ensuring success.

Ready to Take the Next Step?

Transform your production floor with automation that delivers speed, precision, and ROI. Contact us today to discuss your goals and discover how Haffner Machinery can help you scale.