Bridging 2025 Innovations with 2026 Opportunities

As we step into 2026, the fenestration industry is at a pivotal moment. Market dynamics, technological advancements, and evolving customer expectations are reshaping how manufacturers operate. From smart automation to sustainability, here are the trends that will define success in the year ahead.

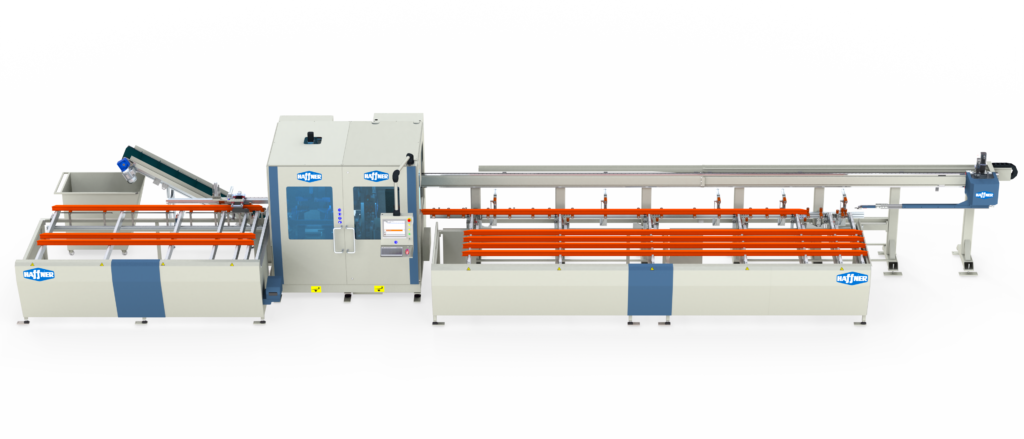

Automation & Smart Production: From Optional to Essential

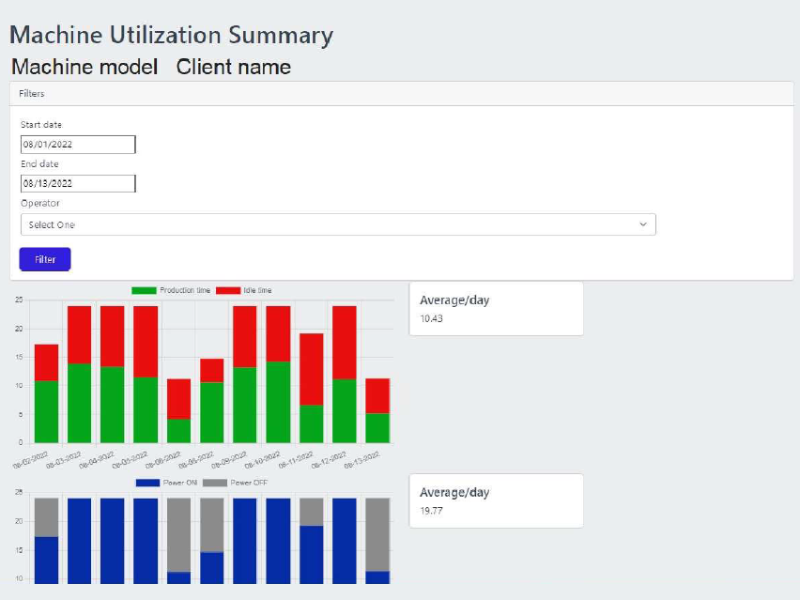

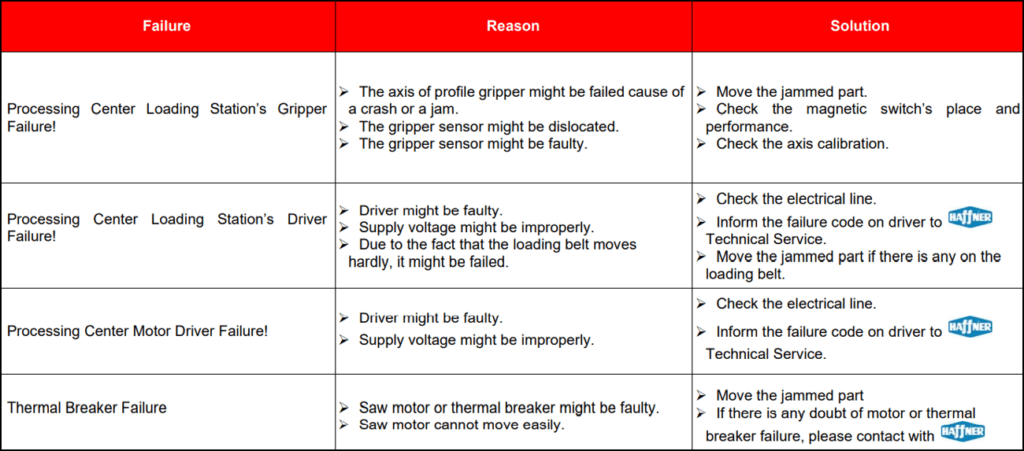

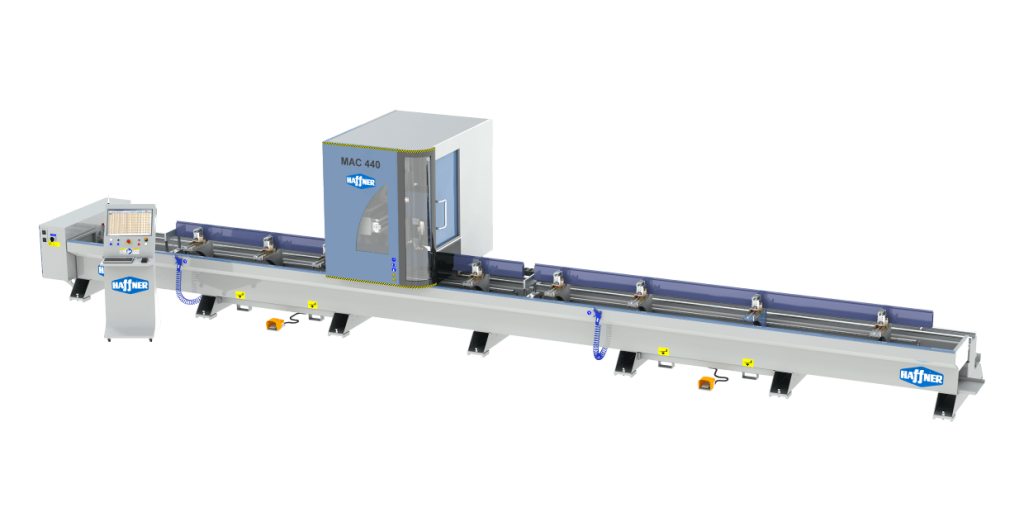

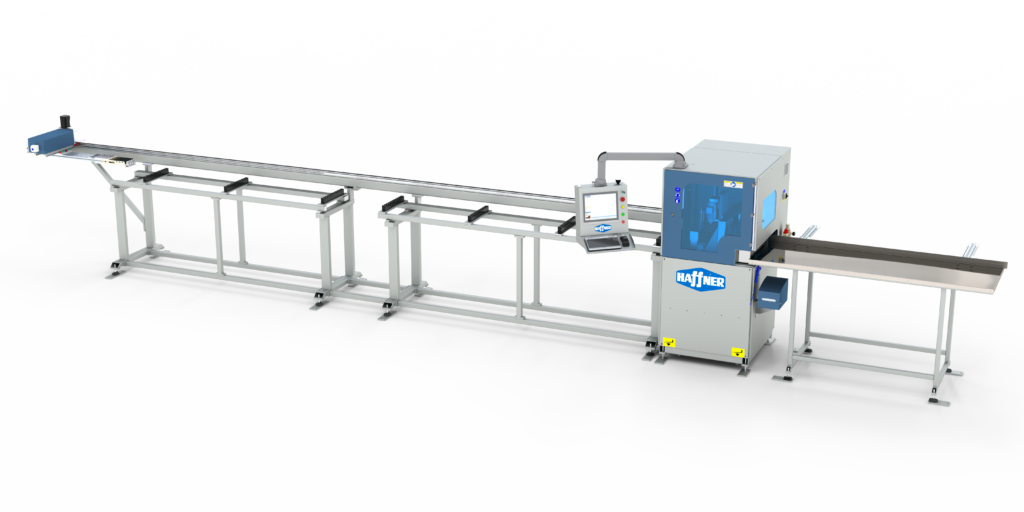

Automation is becoming the backbone of the manufacturing industry. According to recent industry surveys, over 60% of fenestration manufacturers plan to invest in production capacity with tools like automation and smart technology to offset labor shortages and improve throughput. Predictive maintenance and advanced machinery are enabling 24/7 production, reducing errors, and enhancing safety.

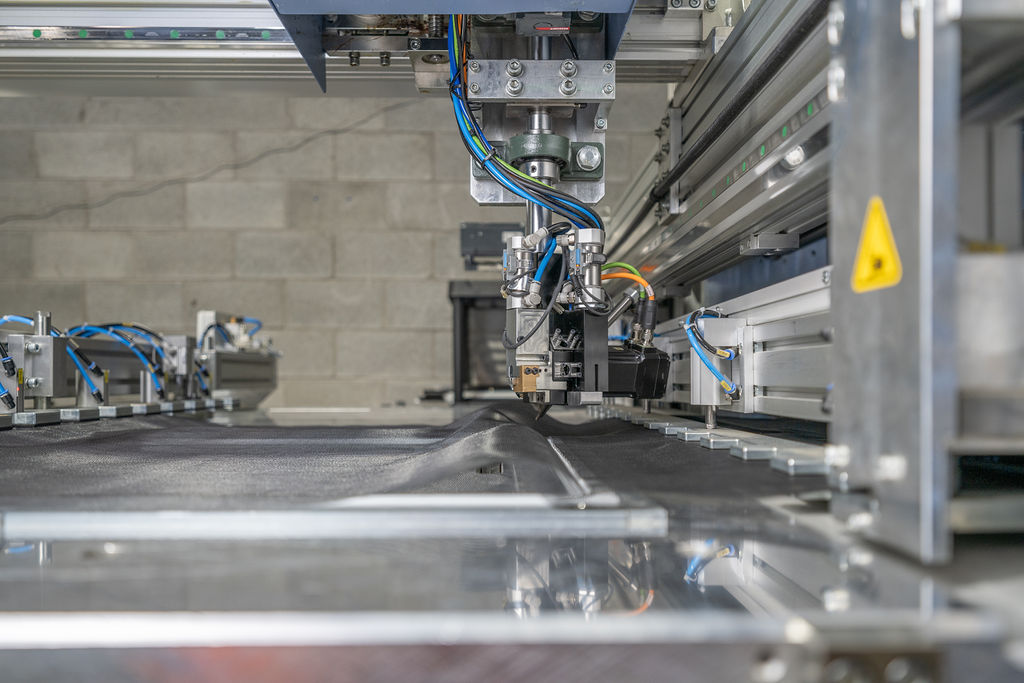

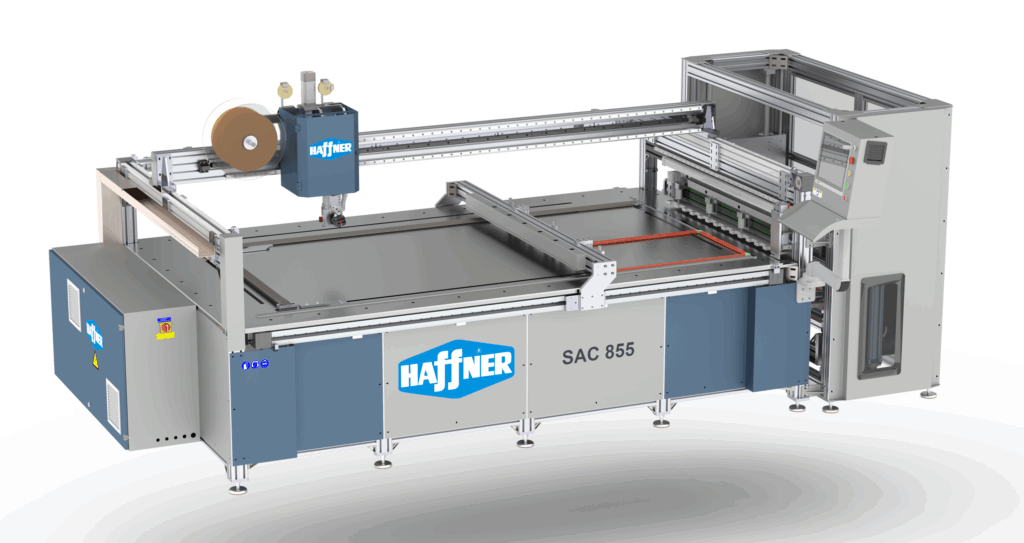

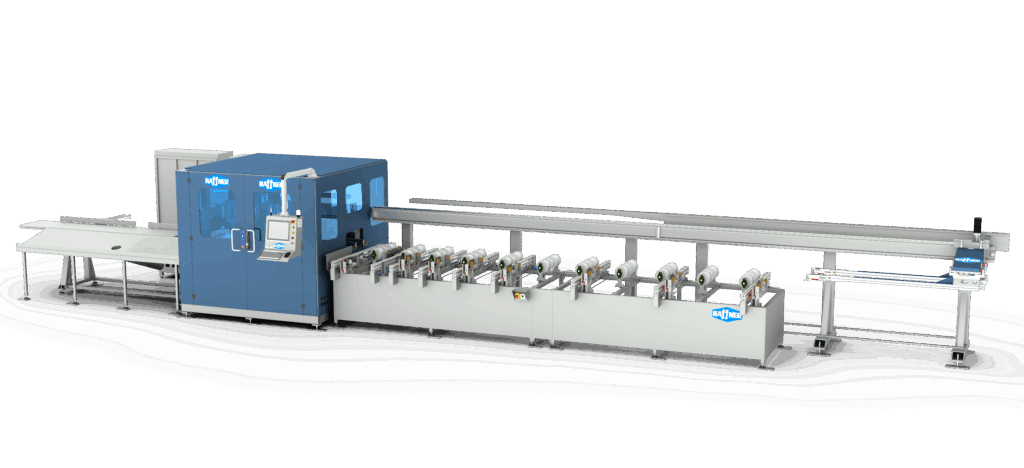

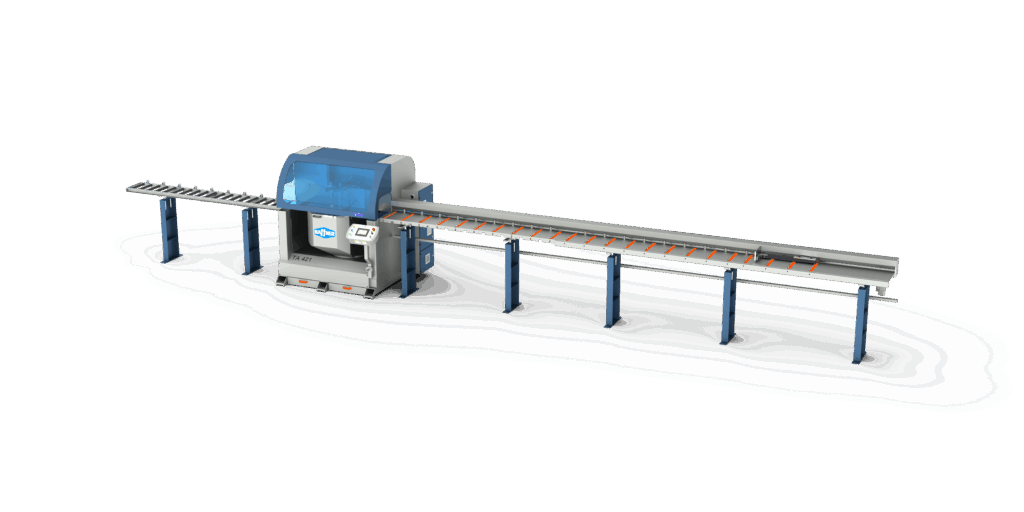

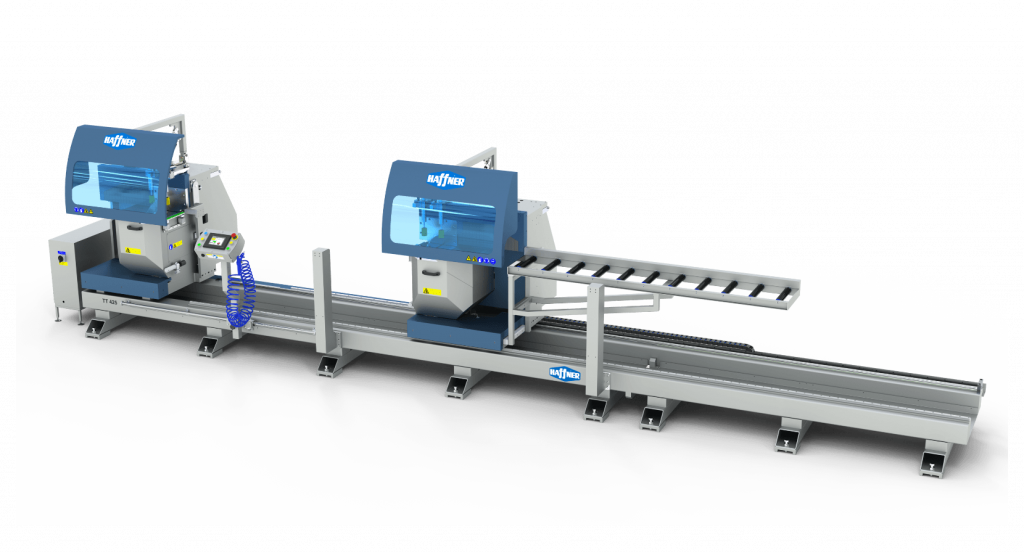

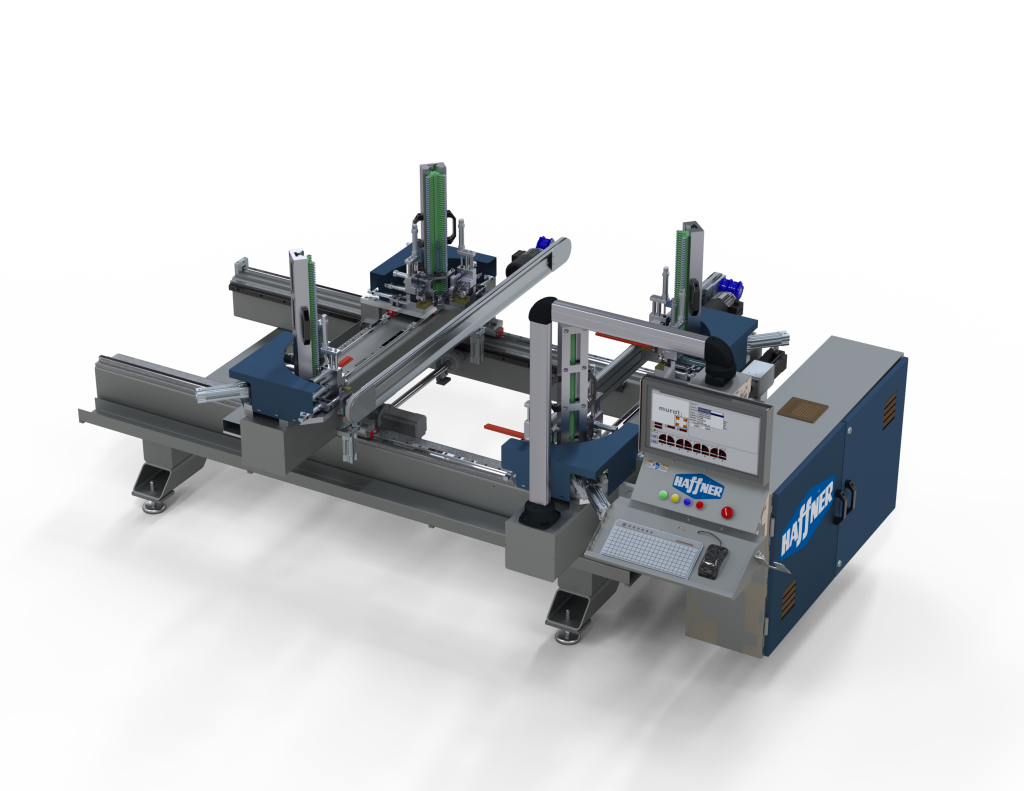

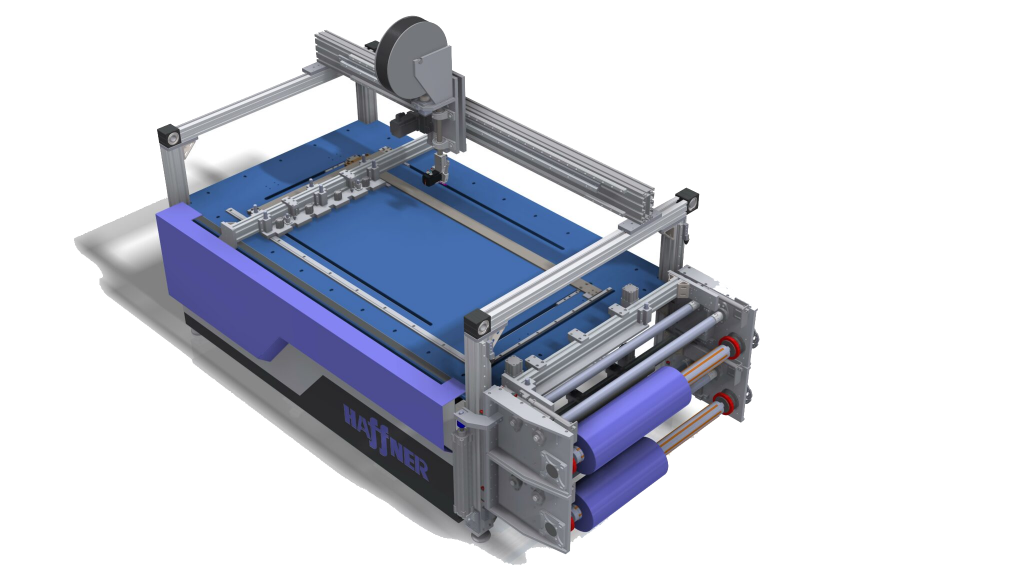

Automated systems like Haffner’s AUTOSCREEN™ demonstrate how companies can produce flawless screens in seconds, freeing skilled labor for higher-value tasks. High-speed automated lines can cut cycle times by up to 25%, reduce defects by 35%, and improve energy efficiency by 20%.

Flexibility & Customization: Meeting Diverse Demands

Customization & scalability are expected. Builders and homeowners want unique sizes, finishes, and smart features. ERP-integrated automation enables manufacturers to pivot quickly without sacrificing throughput. This agility is critical as housing starts are projected to rebound in 2026, driving demand for varied fenestration solutions.

Labor Optimization: Automation as Workforce Strategy

Skilled labor shortages remain severe, especially as manufacturers invest in smarter technologies. A Deloitte survey noted that more than a third of 600 manufacturing executives are concerned with aligning skillsets to maximize smart manufacturing. Investing in talent and leveraging technology is now going hand in hand as 2026 approaches and the skilled labor shortage continues.

Sustainability & Energy Efficiency: Driving Innovation

Energy-efficient fenestration is booming. The global energy-efficient windows market is projected to hit $25 billion by 2028. In general, the windows and doors market is expected to grow at a 4.9% CAGR through 2030, reaching $348 billion by 2032. Green building standards and consumer demand for eco-friendly products are accelerating innovation in fenestration. Expect continued growth in:

- High-performance glazing: Triple-pane, low-E coatings, and dynamic glass technologies.

- Material advancements: Recycled aluminum, composite frames, and thermally broken profiles.

- Smart systems: Automated windows and shading integrated with building management systems to optimize energy use.

The Bottom Line

2026 will reward manufacturers who embrace smart technology, flexibility, and sustainability. Companies like Haffner are leading the charge with advanced machinery that integrates seamlessly into production lines, delivering efficiency without compromising customization or quality.

Looking into 2026, be sure to:

- Audit your production processes for automation opportunities.

- Invest in flexible systems that support rapid customization.

- Align product development with sustainability and smart-home trends.

Ready to get your 2026 workflows started? Partner with Haffner Machinery to plan out the best route to efficiency and success for your fenestration production line.